Description

The board belongs to the DS3800 series of the Mark IV platform, designed for heavy-duty gas turbines (Frame 3, 5, 6, 7, 9) and LM aeroderivative units. The platform’s distributed architecture requires that each subsystem maintain signal isolation and noise immunity, functions primarily handled by boards within the “NF” (Noise Filter/Network Front-end) designation group. The board’s design supports the Mark IV’s hot-swappable maintenance philosophy, allowing replacement without turbine shutdown when proper TMR procedures are followed.

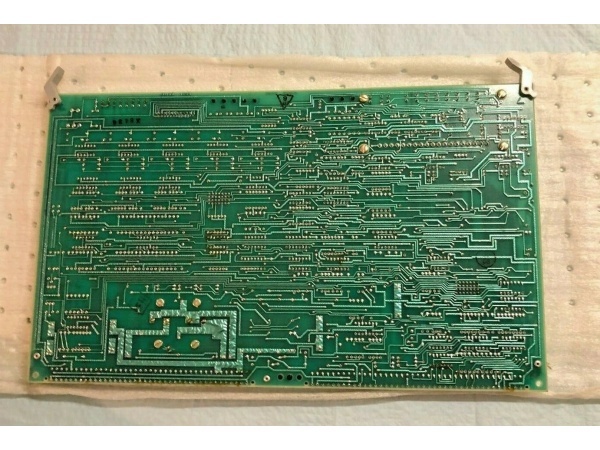

DS3800NFOA1L1G

-

Model Number: DS3800NF0A1L1G

-

Manufacturer: General Electric

-

Product Type: Noise Filter / Network Interface Board

-

Series: GE Speedtronic Mark IV

-

Filtering Function: Common-mode and differential-mode EMI suppression for data or power lines

-

Backplane Interface: High-density modular connector (AMD 218A4553-1 compatible)

-

Passive Components: Ferrite EMI suppression cores, ceramic disk capacitors, metal oxide varistors (MOVs)

-

Circuit Protection: Transient voltage suppression (TVS) diodes, surge current limiting resistors

-

Configuration: Hardware-configurable via soldered jumpers or DIP switches (site-specific)

-

Physical Mounting: Standard Mark IV 6BA09 rack slot with retention levers

-

Operating Temperature: -40°C to +70°C (industrial grade)

-

Humidity: 5% to 95% non-condensing

-

Testing Features: Multiple test points for signal integrity verification and ground continuity checks

Part 4: Core Features & Customer Value

Flexible Configuration for Multi-Application Deployment: Hardware configuration options allow the same base board to be adapted for different site requirements, such as filtering for RS-485 communication networks, analog signal conditioning, or 24/125 VDC power line filtering. This configurability reduces spare parts inventory requirements, as the board can support multiple plant standards through jumper selection or component population changes rather than requiring model-specific variants for each voltage level or signal type.

DS3800NFOA1L1G

Part 5: Typical Applications

The DS3800NF0A1L1G is typically installed in GE Frame 5, 6, and 7 gas turbine Mark IV control cabinets to filter communication lines between the triple modular redundant processors and remote I/O modules. In these applications, the board suppresses noise induced by the turbine’s high-voltage ignition exciters and variable frequency starter motors that could otherwise disrupt the data exchange necessary for voting algorithms. The filtered signal paths are essential for maintaining the synchronization of redundant channels, ensuring that protective functions such as overtemperature and overspeed detection remain reliable even during electrical disturbances.

In steam turbine applications within paper mills, petrochemical facilities, and power plants, this board filters analog servo command signals and feedback lines running to hydraulic valve positioners. The EMI filtering prevents 60 Hz ground loop currents and variable frequency drive harmonics from coupling into the valve position feedback signals, which could cause valve dither, premature actuator wear, or control instability. During plant electrical disturbances or grid faults, the board’s transient suppression capabilities protect the sensitive analog input circuits of servo amplifiers from damage.

In combined-cycle power plants where the Mark IV controls interface with plant Distributed Control Systems (DCS) via serial communication links (Modbus, GE专有协议), the board filters the communication cables running between the turbine skid and control room. The isolation prevents ground potential differences between the turbine base and control building from corrupting data transmissions. This is particularly critical during lightning storms or high-voltage switching operations when transient ground voltage rises could otherwise interrupt the control and monitoring data necessary for coordinated plant operation.

Within the Mark IV’s integrated control and protection architecture, this board filters signals associated with safety shutdown systems, including overspeed protection, vibration monitoring, and emergency stop circuits. By ensuring that these critical safety signals remain free from electrical noise, the board supports the high safety integrity levels (SIL) required for turbine protection systems. The filtered power and signal lines reduce the probability of dangerous failures caused by electromagnetic interference, supporting compliance with IEC 61508/61511 standards for safety instrumented systems.