Description

DS3800NEPB1C1C: Product Overview

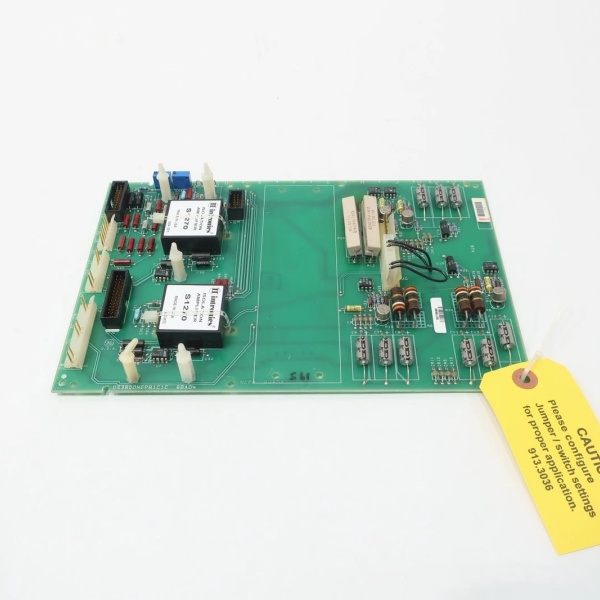

The DS3800NEPB1C1C functions as a critical power conversion and control interface within GE’s Speedtronic Mark IV turbine control architecture. Positioned within the power conversion module, this board receives control signals from the system’s microprocessor and converts them into precisely regulated power outputs that energize the field windings of synchronous motors or generators. The “NEP” designation identifies this as part of the Network/Excitation Power family of boards, specifically designed for motor excitation applications where stable field current is essential for machine performance.

The board incorporates power amplifier stages capable of handling the current demands of medium to large exciter fields, along with feedback signal conditioning circuits that monitor both field current and armature current. These feedback paths enable closed-loop control that maintains constant excitation levels despite variations in machine load, temperature, or supply voltage. The calibration circuit allows field technicians to adjust gain and offset parameters to match specific machine characteristics, while high-voltage resistor networks provide voltage division and power dissipation management for the amplifier stages.

As a member of the DS3800 series, the NEPB1C1C adheres to the standardized form factor and connector scheme established for the Mark IV platform. This standardization enables rapid field replacement and reduces spare parts inventory requirements for facilities maintaining legacy turbine control systems. The board’s design reflects the high-power handling requirements of excitation systems: generous copper traces, thermal management features including a dedicated heatsink assembly, and conservative component ratings that ensure long service life in continuous-duty applications.

DS3800NEPB1C1C

DS3800NEPB1C1C: Technical Specifications

-

Model Number: DS3800NEPB1C1C

-

Manufacturer: General Electric

-

Product Type: Motor Excitation Board

-

System Compatibility: Speedtronic Mark IV Turbine Control

-

Primary Function: Motor/generator excitation power supply and control

-

Power Amplifiers: Integrated power amplification stages for field current drive

-

Feedback Signals: Field current feedback and armature current feedback processing

-

Calibration Circuit: Onboard trimmer adjustments for gain/offset calibration

-

Voltage Handling: High-voltage resistor bridges for voltage division

-

Thermal Management: Integrated heatsink assembly for power dissipation

-

Mounting: Power conversion module installation with ribbon cable backplane interface

-

Safety Requirements: Must power down module and all energy sources before installation

-

Operating Environment: Industrial control cabinet with adequate ventilation

-

Weight: Approximately 0.5 lbs (0.23 kg)

Core Features & Customer Value

Closed-Loop Excitation Control for Machine Stability: The board’s dual feedback architecture—monitoring both field current and armature current—enables precise regulation of excitation levels that maintains generator voltage stability or motor speed control under varying load conditions. For power generation applications, this stability is essential for maintaining grid voltage and reactive power support. In motor applications, consistent field current ensures torque characteristics remain predictable, preventing stall conditions or excessive current draw during load transients.

Field-Calibratable Design for Application Flexibility: The integrated calibration circuit with accessible trimmer adjustments allows commissioning engineers to optimize board response for specific machine parameters. Different generators and motors exhibit varying field time constants and saturation characteristics; the calibration features enable matching the exciter response to these parameters without hardware modifications. For maintenance teams, this means the ability to restore optimal performance after machine rewinds or bearing replacements that alter mechanical characteristics.

Robust Power Handling for Continuous Duty: The power amplifier stages and high-voltage resistor networks are designed with conservative ratings that accommodate the thermal stresses of continuous operation. The dedicated heatsink assembly maintains semiconductor junction temperatures within safe operating areas even when driving high-field-current machines in elevated ambient temperatures. This thermal discipline directly correlates with the extended service intervals typical of baseload power plants, where unplanned outages for board replacement carry severe economic penalties.

Safety-Integrated Installation Design: The board’s requirement for complete power-down before installation reflects the dangerous energy levels present in power conversion modules. High-voltage DC bus capacitors and three-phase AC inputs present lethal hazards that cannot be isolated by simple disconnect switches. The design mandates verification of zero energy state before board extraction, protecting maintenance personnel from arc flash and shock hazards. This safety-first approach aligns with modern lockout/tagout procedures and electrical safety standards.

DS3800NEPB1C1C

Typical Applications

The DS3800NEPB1C1C is deployed in gas turbine generator excitation systems, where it regulates the field current of the synchronous generator to maintain terminal voltage and control reactive power output. In a typical combined-cycle power plant, multiple NEP boards may operate in redundant configurations, each capable of providing full excitation power to ensure continued generation during maintenance or fault conditions. The board’s fast response to voltage transients helps maintain grid stability during system disturbances.

In steam turbine generator applications, this board provides the excitation power for large synchronous generators ranging from tens to hundreds of megawatts. The closed-loop current regulation ensures consistent field excitation despite temperature variations in the field winding that alter resistance. During startup and synchronization sequences, the board responds to automatic voltage regulator (AVR) commands to ramp field current smoothly, preventing voltage overshoot that could damage switchgear or disturb the grid.

The module also finds application in large motor excitation systems for synchronous motors driving compressors, pumps, and fans in industrial processes. In these applications, the board maintains field current during motor starting and running, with the armature current feedback preventing pull-out during load transients. The calibration adjustments allow optimization for different motor designs, from salient-pole to cylindrical-rotor configurations.