Description

DS3800NEPA1E1D Product Overview

The DS3800NEPA1E1D is an exciter-regulator printed-wiring board that resides inside GE Mark IV or EX2000 static-exciter control cubicles. It occupies a mid-rack slot on the 6BA06 Euro-card file and acts as the analog “front end” between the DSP-based CPU and the 480 V SCR bridge: it scales armature-voltage and field-current feedback, generates the ±15 V isolated gate-drive bus, and produces the 24 Vdc field-contactor supply. Because all copper traces are encapsulated in high-temperature epoxy, the board is treated as a line-replaceable module; any over-voltage event that damages internal layers requires a complete card swap rather than field repair. The on-board Freescale 8349 processor (667 MHz) runs the exciter voltage-regulation algorithm, freeing the main CPU from the 2 ms closed-loop task. The module is fully hot-swappable when the rack is powered down, and its 12 W dissipation is low enough to allow adjacent-slot population without additional cooling.

The DS3800NEPA1E1D is an exciter-regulator printed-wiring board that resides inside GE Mark IV or EX2000 static-exciter control cubicles. It occupies a mid-rack slot on the 6BA06 Euro-card file and acts as the analog “front end” between the DSP-based CPU and the 480 V SCR bridge: it scales armature-voltage and field-current feedback, generates the ±15 V isolated gate-drive bus, and produces the 24 Vdc field-contactor supply. Because all copper traces are encapsulated in high-temperature epoxy, the board is treated as a line-replaceable module; any over-voltage event that damages internal layers requires a complete card swap rather than field repair. The on-board Freescale 8349 processor (667 MHz) runs the exciter voltage-regulation algorithm, freeing the main CPU from the 2 ms closed-loop task. The module is fully hot-swappable when the rack is powered down, and its 12 W dissipation is low enough to allow adjacent-slot population without additional cooling.

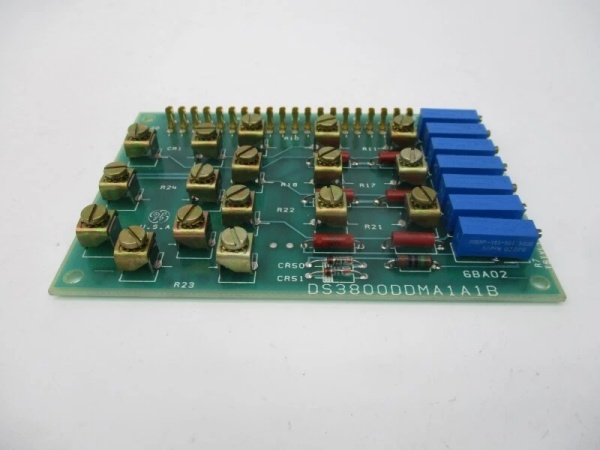

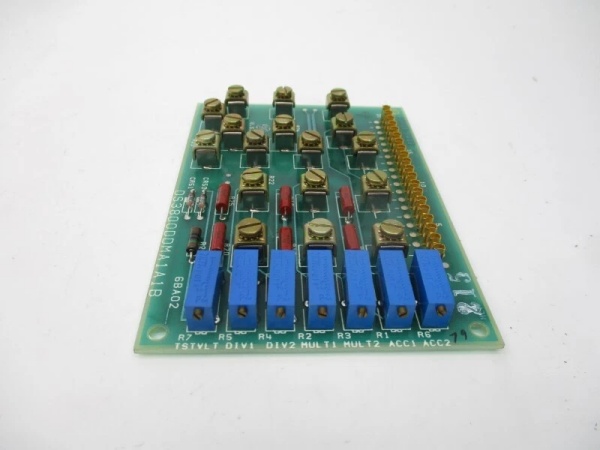

GE DS3800DDMA1A1B

DS3800NEPA1E1E Technical Specifications

-

Model Number: DS3800NEPA1E1D

-

Manufacturer: General Electric (GE Fanuc)

-

Product Type: Exciter Regulator / Analog I/O Interface Board

-

Processor: Freescale 8349 @ 667 MHz

-

Analog Channels: 12 isolated inputs (±10 V, 4–20 mA jumper-selectable)

-

Gate Drive Output: ±15 Vdc isolated, 2 A peak per SCR leg

-

Field Contactor Bus: +24 Vdc @ 3 A (current-limited)

-

Power Supply Input: 18 – 36 Vdc, 12 W max dissipation

-

Isolation: 1500 Vdc channel-to-ground, 2.5 kV optical on gate fibers

-

Operating Temperature: -20 °C to +70 °C

-

Humidity: 5 % – 95 % RH, non-condensing

-

Board Size: 6BA06 Euro-card (≈ 233 × 160 mm)

-

Weight: ≈ 0.22 kg

-

Construction: Epoxy-sealed copper traces—non-repairable

Core Features & Customer Value

Integrated Processor & Regulation Loop: By embedding a 667 MHz Freescale core, the card runs the PID voltage-regulation algorithm locally. This off-loads the main CPU and guarantees the 2 ms loop time stays constant even when the central processor is busy with communications or sequencing tasks. For the operator this means faster VAR response and tighter generator terminal-voltage control during grid disturbances.

Epoxy-Sealed Construction: All internal copper is encapsulated in a high-temperature epoxy. In coastal or industrial sites with conductive dust and high humidity the seal prevents trace-to-trace shorting that would otherwise cause random “EXCITER FAIL” alarms after ten-plus years of service. The trade-off is non-repairability—any surge damage requires a whole-card exchange—but this is offset by the reduced troubleshooting time and the fact that plants stock one spare instead of maintaining a repair bench.

Wide DC Power Window: The board accepts 18 – 36 Vdc directly from the station battery float. This allows the same part number to be used on 24 V or 32 V battery systems without additional DC-DC converters, simplifying spares inventory and reducing wiring errors during retrofit projects.

Typical Applications

In combined-cycle plants the DS3800NEPA1E1D is installed in the Mark IV exciter cubicle where it provides the closed-loop field-current regulator for the brushless exciter. During a black-start the card ramps field current from zero to rated value over a user-defined 30-second curve, preventing over-fluxing of the generator stator. The 12 analog channels also land the three-phase bridge-voltage feedback so the CPU can calculate firing angle in real time.

On mechanical-drive gas compressors the same board is used to ramp inlet-guide-vane position. The follower circuit tracks the manual raise/lower command from the control-room operator, ensuring the vane actuators move smoothly and avoid aerodynamic surge during rapid acceleration. Because the ramp time is jumper-selectable on the component side, field engineers can fine-tune the profile without a software download—useful during commissioning when start curves are still being optimized.