Description

DS3800NDMA1D1B Product Overview

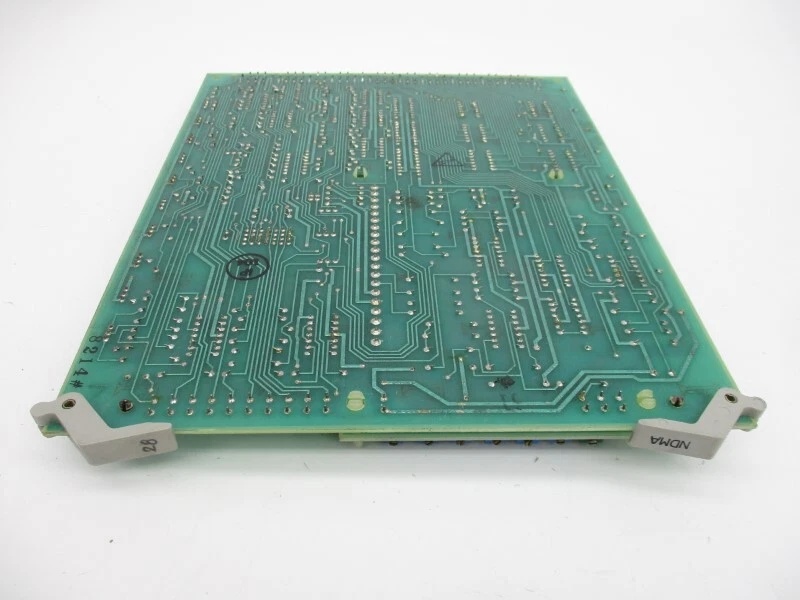

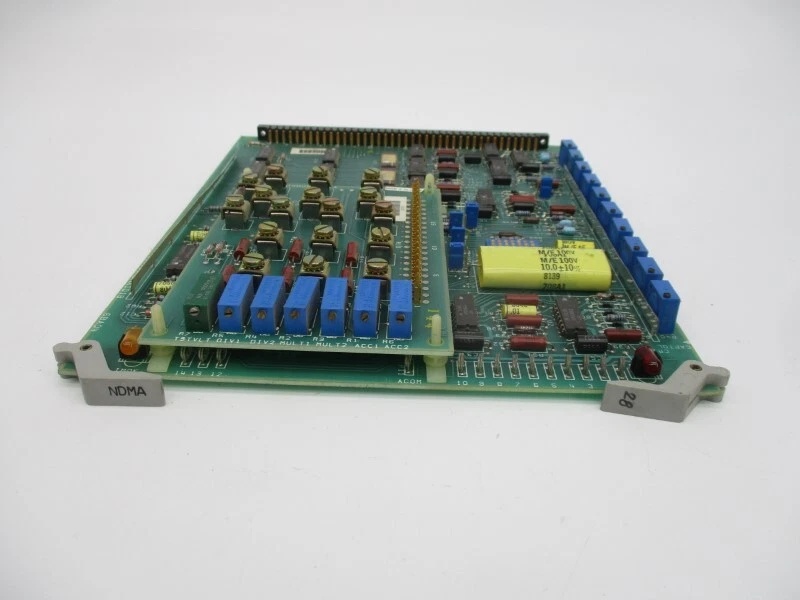

The DS3800NDMA1D1B is an auxiliary data-memory and address-buffer board that resides in GE Mark IV turbine and EX2000 exciter control racks. Occupying a 6BA04 Euro-card slot, it acts as the high-speed bridge between the main CPU (NDIA bus) and expansion SRAM or remote I/O pods: it latches address lines, buffers bi-directional data, and opto-isolates the 5 V processor from the 480 V class power electronics. Because all copper traces are fully encapsulated in high-temperature epoxy, the unit is treated as a line-replaceable module—any internal fault requires a complete card swap rather than component-level rework. The module is fully hot-swappable when the rack is powered down, and its low-profile epoxy package allows adjacent-slot population without additional cooling.

The DS3800NDMA1D1B is an auxiliary data-memory and address-buffer board that resides in GE Mark IV turbine and EX2000 exciter control racks. Occupying a 6BA04 Euro-card slot, it acts as the high-speed bridge between the main CPU (NDIA bus) and expansion SRAM or remote I/O pods: it latches address lines, buffers bi-directional data, and opto-isolates the 5 V processor from the 480 V class power electronics. Because all copper traces are fully encapsulated in high-temperature epoxy, the unit is treated as a line-replaceable module—any internal fault requires a complete card swap rather than component-level rework. The module is fully hot-swappable when the rack is powered down, and its low-profile epoxy package allows adjacent-slot population without additional cooling.

DS3800NDMA1D1B

DS3800NDMA1D1B Technical Specifications

-

Model Number: DS3800NDMA1D1B

-

Manufacturer: General Electric (GE Fanuc)

-

Product Type: Data-Memory & Address Buffer / Auxiliary MPU Board

-

Series: DS3800, Mark IV Speedtronic (NDMA sub-family)

-

Form Factor: 6BA04 Euro-card (≈ 233 × 160 mm)

-

Daughter-Card Mate: DS3800DDMA1A1A (terminal & surge block)

-

Back-Plane Connector: Dual 40-pin header (J1/J2)

-

Data Width: 16-bit address / 16-bit data (buffered)

-

Isolation: 1500 Vdc channel-to-ground; opto-coupled status lines

-

Power Demand: +5 V @ 0.8 A, +15 V @ 0.2 A from rack 2PL bus

-

Operating Temperature: 0 – 60 °C

-

Weight: ≈ 0.22 kg

-

Construction: Epoxy-sealed copper traces—non-repairable

Core Features & Customer Value

High-Speed Address/Data Buffering: The on-board bi-directional buffers maintain <5 ns skew across the 40-pin back-plane. For the control engineer this means the CPU can burst-read memory or I/O at full bus speed without wait-states, ensuring the 2 ms turbine control loop remains deterministic even when the main processor is handling expansion cards.

Epoxy-Sealed Construction: All internal copper is encapsulated in high-temperature epoxy. In environments with high humidity, dust, or conductive contamination the seal prevents trace-to-trace shorting that would otherwise cause random “MEMORY FAIL” alarms after ten-plus years of service. The trade-off is non-repairability—any internal fault requires a whole-card exchange—but this is offset by reduced troubleshooting time and the fact that plants stock one spare instead of maintaining a repair bench.

Plug-and-Play Daughter-Card Interface: The board is normally sold together with terminal block DS3800DDMA1A1A, providing screw-clamp landing for field wiring and on-board MOVs for surge suppression. For maintenance crews this translates to a three-minute replacement instead of a half-shift re-wiring job.

DS3800NDMA1D1B

Typical Applications

In combined-cycle power plants the board is installed in the Mark IV turbine control core where it provides the high-speed data path between the CPU and the expansion memory that stores start-up curves, exhaust-temperature profiles, and fault logs. The on-board opto-isolators keep 480 V switching transients from walking into the 5 V processor data bus.

On utility-scale EX2000 static exciters the same card is used to buffer the real-time firing-angle data between the main CPU and the remote bridge-interface cards. Because the memory is local to the buffer, fault history is preserved even if the station battery is disconnected during maintenance.

Frequently the same part number is used on mechanical-drive gas compressors to expand the data-throughput capacity of the inlet-guide-vane control loop. Its ability to mix high-speed address buffering with isolation on one card makes it a universal “data expander” for any Mark IV loop that needs deterministic, battery-free operation.