Description

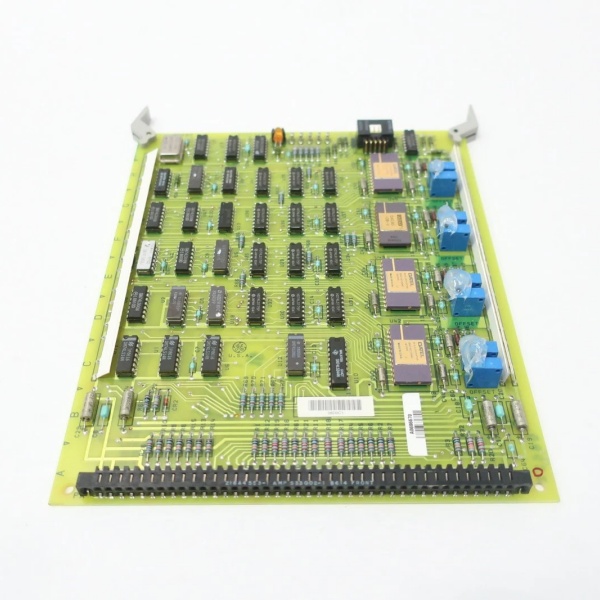

DS3800NDAC1D1E: Product Overview

The DS3800NDAC1D1E serves as a critical output interface within GE’s Speedtronic Mark IV turbine control architecture. Positioned in the output stage of the control system, this board converts digital control commands from the system’s microprocessors into precise analog signals that drive field actuators, valve positioners, and process indicators. The “NDAC” designation identifies this as a network digital-to-analog converter module optimized for high-precision control applications in power generation and industrial automation environments.

The board incorporates a sophisticated array of eight adjustable variable resistors (potentiometers) that enable fine-tuning of output signal scaling and offset characteristics. These trimmers allow field technicians to calibrate each output channel to match specific actuator requirements without software modifications. Multiple EPROM and EEPROM devices store both fixed conversion algorithms and configurable parameters, ensuring consistent behavior while allowing site-specific customization. A crystal oscillator provides the precise timing reference necessary for stable, low-drift analog output generation.

As a member of the DS3800 series, the NDAC1D1E adheres to the standardized form factor and connector scheme established for the Mark IV platform. This standardization enables rapid field replacement and reduces spare parts inventory requirements for facilities maintaining legacy turbine control systems. The board’s design reflects the industrial control philosophy of the 1980s and 1990s: extensive use of socketed components for maintainability, conservative electrical design margins, and robust mechanical retention features that withstand decades of thermal cycling in power plant environments.

GE DS3800NDAC1D1E

DS3800NDAC1D1E: Technical Specifications

-

Model Number: DS3800NDAC1D1E

-

Manufacturer: General Electric

-

Product Type: Analog Output Board

-

System Compatibility: Speedtronic Mark IV Turbine Control

-

DAC Channels: Multiple analog output channels (typically 4-8 channels)

-

Output Signal Types: Voltage and current outputs (configurable)

-

Adjustment Components: 8 adjustable variable resistors (potentiometers)

-

Memory Configuration: EPROM modules (fixed firmware) and EEPROM (configurable parameters)

-

Timing Reference: Crystal oscillator for precise frequency generation

-

Backplane Interface: 40-slot female ribbon cable connector with retention snaps

-

Diagnostic Indicators: Pale yellow LED for operational status; additional diagnostic LEDs

-

Passive Components: 74 resistors with categorized current capacities; multiple diodes (sandy, red, silver, blue-green)

-

Mounting: Standard DS3800 series card cage with screw points and fasteners

-

Operating Temperature: 0°C to +70°C (standard industrial range)

-

Storage Temperature: -40°C to +85°C

-

Humidity Tolerance: 5% to 95% non-condensing

-

Weight: Approximately 0.5 lbs (0.23 kg)

Core Features & Customer Value

Precision Analog Signal Generation for Accurate Control: The board’s digital-to-analog conversion circuitry, supported by crystal oscillator timing, generates analog outputs with high resolution and low drift characteristics essential for closed-loop control. Turbine fuel valves, inlet guide vanes, and extraction dampers all require precise positioning signals to maintain optimal combustion efficiency and emissions compliance. For plant operators, this precision translates to stable unit operation, improved heat rates, and reduced likelihood of trips caused by control signal instability or actuator hunting.

Field-Calibratable Design for Application Flexibility: The eight onboard potentiometers enable adjustment of gain, offset, and linearity parameters for each output channel without requiring software downloads or configuration tool access. This hardware-level calibration capability proves invaluable during commissioning when matching the board’s output characteristics to specific actuator response curves, or during maintenance when compensating for component aging in the field device. Technicians can perform calibration using standard test equipment, reducing dependency on specialized proprietary tools.

Robust Memory Architecture for Operational Reliability: The separation between EPROM and EEPROM memory types provides both stable operational firmware and field-configurable parameters. The EPROM contains the core DAC algorithms that remain fixed throughout the board’s service life, ensuring consistent conversion behavior. The EEPROM stores site-specific scaling factors, output range limits, and diagnostic thresholds that can be modified through the Mark IV interface. When replacement becomes necessary, transferring the EEPROM to a spare board preserves all calibration data, eliminating post-replacement commissioning time.

Comprehensive Diagnostic Visibility: The board incorporates multiple LED indicators that provide real-time visibility into operational status. The primary pale yellow LED indicates power and basic operational state, while additional diodes (sandy, red, silver, and blue-green) offer granular diagnostic information about individual channel activity, memory access patterns, and fault conditions. For troubleshooting intermittent issues, these visual indicators enable rapid identification of failed channels without requiring oscilloscope or multimeter probing of live circuits.

GE DS3800NDAC1D1E

Typical Applications

The DS3800NDAC1D1E is deployed in gas turbine fuel valve control systems, where it generates analog position commands for hydraulic servo valves that regulate natural gas or liquid fuel flow to combustion chambers. In a typical Frame 7 or Frame 9 heavy-duty gas turbine, multiple NDAC boards operate in parallel—each controlling specific valve quadrants to ensure even fuel distribution and prevent combustion hot spots that degrade turbine life. The board’s precise output scaling ensures that fuel flow matches the calculated demand from the control algorithms within tight tolerances.

In steam turbine admission valve control, this board provides analog signals to electro-hydraulic actuators that regulate high-pressure steam flow to turbine cylinders. The fast update rates and low output impedance ensure responsive valve action during load transients, while the calibration trimmers allow matching to the specific stroke characteristics of each valve actuator. Accurate valve positioning is essential for sliding pressure operation and advanced load control strategies that improve heat rate efficiency in combined-cycle applications.

The module also serves in turbine auxiliary system control, driving analog inputs to variable frequency drives for cooling fans, lube oil pumps, and hydraulic power units. In these applications, the board’s configurable output ranges (typically 4-20mA or 0-10V) accommodate different drive input requirements without hardware changes. The isolation between channels prevents ground loop interactions between multiple drives that share a common control reference.