Description

DS3800NCVA1A1C: Product Overview

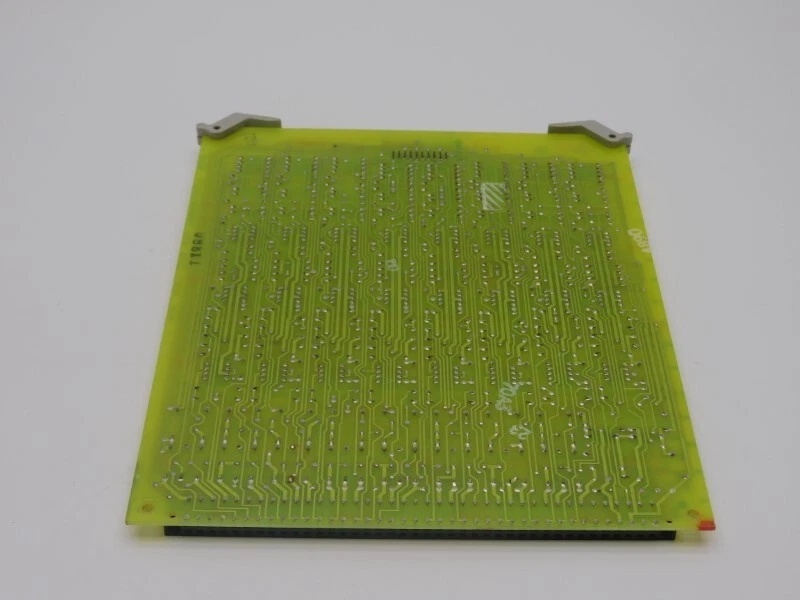

The DS3800NCVA1A1C functions as a critical analog input interface within GE’s Speedtronic Mark IV turbine control architecture. Positioned in the input/output section of the system, this board receives standard 4-20mA current loop signals from field transmitters and converts them into digital representations that the Mark IV’s central processors can utilize for control decisions. These current loops typically carry process variables such as bearing temperatures, lube oil pressures, fuel flow rates, and compressor discharge pressures—parameters essential for safe and efficient turbine operation.

The board incorporates dedicated signal conditioning circuits that isolate, filter, and scale incoming analog signals. This processing chain includes impedance matching networks, electromagnetic interference (EMI) filters, and analog-to-digital conversion stages. The conditioned signals are then transmitted via the Mark IV’s triple-modular-redundant (TMR) backplane to the system’s main processors, where they participate in voting algorithms that ensure control integrity even in the presence of single-point failures.

As a member of the DS3800 series, the NCVA1A1C adheres to the standardized form factor and connector scheme that GE established for the Mark IV platform. This standardization allows rapid field replacement and reduces spare parts inventory requirements. The board’s design reflects the era’s industrial control philosophy: discrete component reliability, conservative operating margins, and extensive use of socketed integrated circuits to facilitate maintenance. The Mark IV system, introduced in the 1980s, represented GE’s first TMR turbine control architecture and remains operational in numerous baseload power generation facilities worldwide.

DS3800NCVA1A1C

DS3800NCVA1A1C: Technical Specifications

-

Model Number: DS3800NCVA1A1C

-

Manufacturer: General Electric

-

Product Type: Current Loop Input Board

-

System Compatibility: Speedtronic Mark IV Turbine Control

-

Input Signal Type: 4-20mA current loop (industry standard process control signal)

-

Backplane Interface: Ribbon cable connector (left-edge mounting)

-

Isolation: Galvanic isolation between field inputs and internal logic

-

Signal Conditioning: Onboard filtering and scaling circuits

-

Memory: Socketed EEPROM for channel calibration data

-

Mounting: Standard DS3800 series card cage with retention hardware

-

Operating Environment: Industrial control room, forced air cooling required

-

Weight: Approximately 0.5 lbs (0.23 kg)

Core Features & Customer Value

Robust Signal Integrity in Noisy Environments: The board’s multi-stage input conditioning includes passive filtering and active buffering that reject common-mode noise typically present in power plant environments. Long cable runs from field transmitters to the control cabinet often pick up electromagnetic interference from high-voltage switchgear and rotating machinery. The NCVA1A1C’s filtering architecture ensures that control decisions are based on actual process conditions rather than electrical noise, preventing unnecessary turbine trips that can cost utilities hundreds of thousands of dollars in lost generation revenue.

Maintainable Architecture for Extended Service Life: The socketed EEPROM design allows complete calibration data preservation during board replacement. When a channel requires recalibration or a board must be swapped, technicians can transfer the EEPROM to the replacement unit, maintaining the exact scaling and offset parameters established during commissioning. This feature eliminates the need for post-replacement calibration procedures that require taking measurements offline—a significant advantage in baseload plants where availability premiums are high.

Triple-Modular-Redundant Compatibility: The NCVA1A1C is designed specifically for the Mark IV’s TMR architecture, where three identical boards (one per control channel) process the same field signals simultaneously. The board’s deterministic response characteristics ensure that all three channels produce identical digital outputs when presented with the same analog input, allowing the system’s voting logic to identify and isolate failed channels without affecting turbine operation. This redundancy level was revolutionary when introduced and remains a benchmark for safety instrumented systems in power generation.

DS3800NCVA1A1C

Typical Applications

The DS3800NCVA1A1C is deployed in gas turbine lube oil system monitoring, where it receives 4-20mA signals from pressure transmitters monitoring bearing header pressures and temperature transmitters monitoring oil cooler performance. In a typical Frame 6 or Frame 7 heavy-duty gas turbine, eight to twelve NCVA boards may be installed to handle the full complement of lubrication system sensors, with each board managing multiple loops to provide the control system with real-time visibility into mechanical health.

In steam turbine generator set applications, this board processes signals from stator winding temperature monitors, hydrogen cooling pressure sensors, and excitation system current transducers. The current loop interface provides the galvanic isolation necessary to safely bring high-voltage zone signals into the low-voltage control cabinet. The board’s fast update rates (typically 50-100ms per channel) enable the Mark IV to detect rapid temperature excursions during load transients or cooling system disturbances.

The module also serves in fuel gas metering and valve position indication systems, where it converts signals from flow computers and valve positioners into digital feedback for the turbine’s fuel control algorithms. Accurate current loop measurement at this stage is critical for emissions compliance and combustion stability, particularly during low-load operation where fuel/air mixing becomes more sensitive to flow measurement errors.