Description

Part 3: Detailed Product Description

DS3800HXRC1D1C: Product Overview

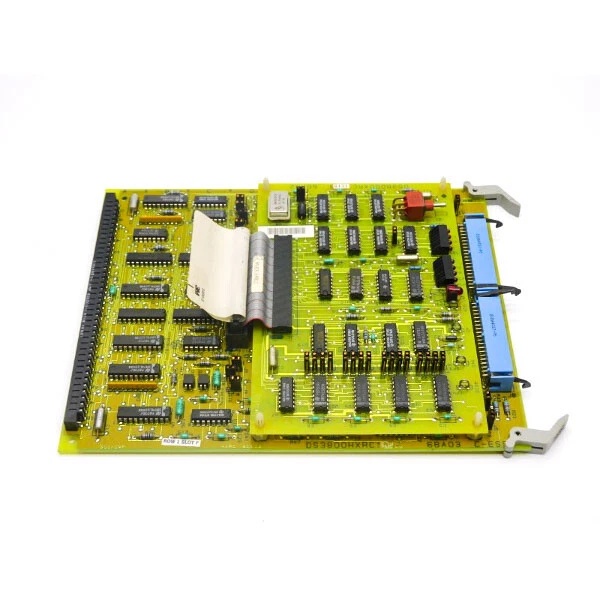

The board functions as a high-speed signal reception and distribution module within GE’s Speedtronic Mark IV turbine control architecture. Positioned within the control rack assembly, this unit serves as the critical interface between high-speed field sensors and the central processing modules. In the Mark IV’s triple modular redundant (TMR) system, this board operates within each independent control channel, ensuring that high-speed data from turbine protection systems reaches the processors with minimal latency and maximum integrity.

As a high-speed expander receiver, the unit manages the rapid signal acquisition necessary for turbine protection functions such as overspeed detection, vibration monitoring, and combustion instability sensing. It receives pulse signals, high-frequency digital communications, and fast-acting discrete inputs from field devices, conditioning these signals to logic levels compatible with the Mark IV microprocessor architecture. The board’s circuitry provides buffering, noise filtering, and signal amplification to ensure that critical protection signals are not degraded by electromagnetic interference or cable capacitance effects over long distances.

The board features integrated EPROM sockets that allow configuration of signal processing parameters for specific turbine applications. These non-volatile memory devices store calibration constants, threshold levels, and signal conditioning parameters that tailor the board’s response to different sensor types. The retention levers ensure positive engagement with the rack backplane while facilitating hot-swappable maintenance in redundant configurations.

This board belongs to the DS3800 series of the Mark IV platform, deployed across heavy-duty gas turbines (Frame 3, 5, 6, 7, 9) and LM aeroderivative units. The platform’s deterministic architecture requires that signal reception and distribution maintain microsecond-level timing precision to ensure coordinated turbine protection across three redundant channels.

GE DS3800HXRC1D1C

DS3800HXRC1D1C: Technical Specifications

-

Model Number: DS3800HXRC1D1C

-

Manufacturer: General Electric

-

Product Type: High-Speed Expander Receiver Board

-

Series: GE Speedtronic Mark IV

-

Architecture: Triple Modular Redundant (TMR) compatible

-

Signal Reception: High-speed digital pulse and discrete input conditioning

-

Memory: Multiple IC sockets for EPROM configuration storage

-

Backplane Interface: High-density modular connector (AMD 218A4553-1 compatible)

-

Status Indication: 6 diagnostic LEDs (signal activity and fault indication)

-

Test Access: 12 test points for signal verification and troubleshooting

-

Logic Interface: TTL-compatible signal levels with noise filtering

-

Mounting: Standard Mark IV rack slot with integrated retention levers

-

Operating Temperature: -40°C to +70°C (industrial grade)

-

Humidity: 5% to 95% non-condensing

-

Vibration/Shock: 5 g vibration / 50 g shock (per Mark IV specifications)

-

Power Supply: Derived from Mark IV rack backplane (+5 VDC logic)

Part 4: Core Features & Customer Value

High-Speed Signal Integrity for Critical Protection: The board’s primary function is to maintain signal fidelity for high-speed protection inputs where millisecond delays could result in machinery damage. By providing dedicated reception circuitry with controlled impedance matching and Schmitt trigger buffering, the board ensures that pulse signals from magnetic pickups, tachometers, and high-speed limit switches arrive at the processor without distortion or timing jitter. For protection engineers, this means reliable overspeed detection and rapid response to transient conditions that could compromise turbine integrity.

Field-Configurable Reception Parameters: The EPROM sockets allow site-specific configuration of input filtering time constants, threshold voltages, and signal debounce parameters without hardware modifications. This flexibility enables the same board to interface with diverse sensor types—from passive magnetic pickups generating low-voltage pulses to active proximity switches providing conditioned outputs. During commissioning, engineers can optimize the board’s response characteristics for specific sensor cable lengths and installation environments, reducing false trips caused by electrical noise while maintaining sensitivity to genuine fault conditions.

Comprehensive Diagnostic Visibility: The six LEDs provide immediate visual confirmation of signal presence, channel activity, and fault states without requiring diagnostic software connections. Technicians can verify that sensors are generating signals, that the reception circuitry is processing those signals, and that the backplane connection is communicating with the central processor. This visibility reduces troubleshooting time during startup and commissioning, allowing rapid verification of sensor wiring integrity and signal polarity before the turbine is brought to operating speed.

Robust Isolation and Noise Immunity: The board incorporates galvanic isolation and filtering components that prevent ground loop currents and common-mode noise from corrupting high-speed signal edges. In industrial environments with high-voltage switching equipment and variable frequency drives, these protection features ensure that low-level pulse signals remain distinguishable from electrical noise. For maintenance managers, this translates to reduced nuisance trips and fewer emergency shutdowns caused by intermittent electrical interference.

Hot-Swappable Design with Mechanical Integrity: The retention levers provide secure mechanical mounting in high-vibration environments while enabling rapid replacement during maintenance windows. In TMR configurations, technicians can replace a failed reception board while the remaining two channels maintain turbine protection, eliminating the need to shut down the unit for signal interface maintenance. The positive locking mechanism prevents vibration-induced loosening that could cause intermittent contact failures—a critical reliability feature given the obsolete status of the Mark IV platform and the difficulty in sourcing replacement components.

GE DS3800HXRC1D1C

Part 5: Typical Applications

Gas Turbine Overspeed Protection Systems:

The DS3800HXRC1D1C is deployed in GE Frame 5, 6, and 7 gas turbines to receive pulse signals from magnetic pickups monitoring turbine shaft speed. In these applications, the board conditions the low-voltage pulses generated by the pickups as gear teeth pass the sensor, converting them to clean digital transitions for the overspeed protection logic. The high-speed reception capability ensures that the control system detects acceleration rates that could indicate runaway conditions, triggering fuel trip valves within milliseconds. The EPROM configuration allows calibration of the pickup sensitivity and threshold levels to match specific gear geometries and magnetic pickup specifications.

The DS3800HXRC1D1C is deployed in GE Frame 5, 6, and 7 gas turbines to receive pulse signals from magnetic pickups monitoring turbine shaft speed. In these applications, the board conditions the low-voltage pulses generated by the pickups as gear teeth pass the sensor, converting them to clean digital transitions for the overspeed protection logic. The high-speed reception capability ensures that the control system detects acceleration rates that could indicate runaway conditions, triggering fuel trip valves within milliseconds. The EPROM configuration allows calibration of the pickup sensitivity and threshold levels to match specific gear geometries and magnetic pickup specifications.

Vibration Monitoring Signal Conditioning:

In turbine applications utilizing proximity probes for shaft vibration and thrust position monitoring, this board receives the high-frequency signal components necessary for orbit analysis and bearing condition assessment. It distributes these signals to the Mark IV’s vibration monitoring modules while providing isolation between the probe driver circuits and the control logic. The board’s noise filtering capabilities are essential in this application, as vibration signals measured in millivolts are susceptible to corruption from electromagnetic interference generated by the turbine’s excitation system or switchyard operations.

In turbine applications utilizing proximity probes for shaft vibration and thrust position monitoring, this board receives the high-frequency signal components necessary for orbit analysis and bearing condition assessment. It distributes these signals to the Mark IV’s vibration monitoring modules while providing isolation between the probe driver circuits and the control logic. The board’s noise filtering capabilities are essential in this application, as vibration signals measured in millivolts are susceptible to corruption from electromagnetic interference generated by the turbine’s excitation system or switchyard operations.

Steam Turbine Emergency Trip Systems:

In steam turbine installations within petrochemical facilities and power plants, the board receives discrete inputs from emergency trip devices such as overspeed governors, low oil pressure switches, and manual trip stations. The high-speed reception ensures that these protective signals are recognized immediately, bypassing any software processing delays that could compromise safety. The board’s configurable input parameters accommodate both dry contact switches and solid-state sensors, allowing integration of legacy mechanical protection systems with modern electronic controls during turbine retrofit projects.

In steam turbine installations within petrochemical facilities and power plants, the board receives discrete inputs from emergency trip devices such as overspeed governors, low oil pressure switches, and manual trip stations. The high-speed reception ensures that these protective signals are recognized immediately, bypassing any software processing delays that could compromise safety. The board’s configurable input parameters accommodate both dry contact switches and solid-state sensors, allowing integration of legacy mechanical protection systems with modern electronic controls during turbine retrofit projects.

Aeroderivative Turbine Speed Sensing:

For LM6000 and LM2500 units, the board receives high-resolution speed signals from the turbine’s starter and power turbine sections. These signals coordinate the starter disengagement sequence and monitor turbine acceleration during startup. The board’s ability to handle high pulse rates supports the fine speed resolution required for aero-derivative turbines, which operate at higher speeds than heavy-duty frame units. The LED indicators provide local confirmation of speed signal presence during borescoping or maintenance activities when diagnostic computers may not be available.

For LM6000 and LM2500 units, the board receives high-resolution speed signals from the turbine’s starter and power turbine sections. These signals coordinate the starter disengagement sequence and monitor turbine acceleration during startup. The board’s ability to handle high pulse rates supports the fine speed resolution required for aero-derivative turbines, which operate at higher speeds than heavy-duty frame units. The LED indicators provide local confirmation of speed signal presence during borescoping or maintenance activities when diagnostic computers may not be available.

Combustion Dynamics Monitoring:

In advanced gas turbine applications utilizing dynamic pressure sensors to monitor combustion instabilities, this board receives high-frequency pressure fluctuation signals. It conditions these signals for spectral analysis by the Mark IV’s combustion monitoring algorithms, detecting precursor conditions to combustion instabilities that could damage turbine hardware. The board’s signal conditioning circuitry preserves the high-frequency content of these dynamic signals while filtering electrical noise from the ignition excitation systems.

In advanced gas turbine applications utilizing dynamic pressure sensors to monitor combustion instabilities, this board receives high-frequency pressure fluctuation signals. It conditions these signals for spectral analysis by the Mark IV’s combustion monitoring algorithms, detecting precursor conditions to combustion instabilities that could damage turbine hardware. The board’s signal conditioning circuitry preserves the high-frequency content of these dynamic signals while filtering electrical noise from the ignition excitation systems.