Description

DS3800HXPE1A1A: Product Overview

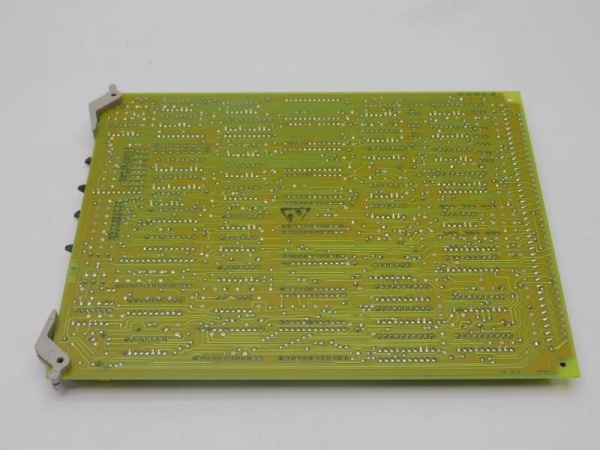

The board serves as a microprocessor expander interface within GE’s Speedtronic Mark IV turbine control architecture. Positioned within the control rack assembly, this module provides the expanded input/output capabilities and peripheral interfacing necessary to support complex turbine control algorithms. In the Mark IV’s triple modular redundant (TMR) system, this board operates within each independent control channel, extending the processing and interfacing capabilities of the main CPU modules.

As a microprocessor expander, the unit addresses the limited I/O pin availability of base microprocessors by providing additional ports, memory expansion sockets, and specialized interfaces. It enables the integration of a greater number of sensors, actuators, and communication peripherals than the base processor architecture alone would support. The board typically hosts electrically erasable programmable read-only memory (EEPROM) modules that store firmware, configuration parameters, and application-specific code for the control system’s operation.

The board features retention levers for secure installation in the Mark IV rack, ensuring positive engagement with the backplane connector while facilitating hot-swappable maintenance procedures. Configurable jumpers allow field adaptation to specific turbine models and application requirements, supporting the diverse range of Frame 3, 5, 6, 7, 9 gas turbines and LM aeroderivative units within the Mark IV installed base.

This board belongs to the DS3800 series, representing the fourth generation of GE’s turbine control systems. The platform’s distributed architecture allows this expander to operate autonomously while maintaining deterministic synchronization with the primary control processors, ensuring that expanded I/O functions remain coordinated with critical turbine protection and control loops.

GE DS3800HXPE1A1A

DS3800HXPE1A1A: Technical Specifications

-

Model Number: DS3800HXPE1A1A

-

Manufacturer: General Electric

-

Product Type: Microprocessor Expander Interface Board

-

Series: GE Speedtronic Mark IV

-

Function: CPU I/O expansion and peripheral interface

-

Memory Support: Multiple EEPROM sockets for firmware and parameter storage

-

Configuration: Hardware jumpers for operational mode selection

-

Mounting: Standard Mark IV rack slot with retention levers

-

Backplane Interface: High-density modular connector (AMD 218A4553-1 compatible)

-

Operating Temperature: -35°C to +65°C (industrial grade)

-

Storage Temperature: -40°C to +85°C

-

Physical Dimensions: Approximately 8.25 cm × 4.15 cm (standard Mark IV form factor)

-

Weight: Approximately 0.4 kg (0.9 lb)

-

Humidity: 5% to 95% non-condensing

-

Vibration/Shock: 5 g vibration / 50 g shock (per Mark IV cabinet specifications)

-

Power Supply: Derived from Mark IV rack backplane (+5 VDC logic power)

Part 4: Core Features & Customer Value

Expanded I/O Capability for Complex Control: The primary function of this expander board is to overcome the physical I/O limitations of base microprocessors in the Mark IV system. By providing additional input/output channels, the board enables integration of comprehensive sensor arrays and actuator networks required for modern turbine control. This expansion capability allows the control system to monitor more points—such as additional thermocouples, vibration probes, and pressure transmitters—without requiring additional CPU modules, reducing system cost and complexity while maintaining the deterministic performance required for turbine protection.

Firmware Flexibility with EEPROM Architecture: The board incorporates multiple sockets for EEPROM modules that store executable code and configuration data. This architecture allows site-specific control algorithms, startup curves, and fuel scheduling maps to be customized by replacing firmware chips rather than modifying hardware or downloading software. For field engineers, this means rapid adaptation to turbine modifications or retrofits; for maintenance managers, it means the ability to preserve proprietary control strategies while replacing failed hardware, ensuring continuity of operational knowledge across decades of service.

Hot-Swappable Design with Retention Levers: The integrated retention levers ensure secure mechanical mounting in high-vibration turbine environments while enabling rapid extraction and insertion during maintenance. This design supports the Mark IV’s TMR hot-swap philosophy, allowing technicians to replace expander boards while the turbine remains operational on redundant channels. The positive locking mechanism prevents vibration-induced loosening that could cause intermittent contact failures, a critical reliability feature in continuous-duty power generation applications.

Hardware Configuration for Multi-Application Support: Onboard jumpers allow the same physical board to be configured for different turbine models and application codes without hardware modifications. This configurability reduces spare parts inventory requirements—facilities can stock one board type to support multiple turbine frames or configurations, selecting operational modes via jumper settings during installation. This flexibility is particularly valuable for power plants with mixed turbine fleets or for OEM spare parts distributors serving diverse utility customers.

Robust Industrial Environmental Ratings: With specifications for 5G vibration resistance and extended temperature operation, the board withstands the mechanical and thermal stresses typical of turbine control enclosures. The industrial-grade components ensure long-term reliability in environments subject to thermal cycling, electromagnetic interference from high-voltage switchgear, and mechanical vibration from rotating equipment. For asset managers, this durability translates to extended Mean Time Between Failures (MTBF) and reduced lifecycle costs despite the obsolete status of the Mark IV platform.

GE DS3800HXPE1A1A

Part 5: Typical Applications

Heavy-Duty Gas Turbine Control Expansion:

The DS3800HXPE1A1A is deployed in GE Frame 5, 6, and 7 gas turbines to expand the I/O capacity of the main microprocessor boards. In these applications, the board provides additional analog and digital interfaces for exhaust temperature monitoring systems, combustion dynamics instrumentation, and fuel system position feedback. The EEPROM sockets store turbine-specific fuel curves and startup sequences optimized for different ambient conditions or fuel qualities. During commissioning, engineers configure the jumpers to match the specific frame and application, enabling standardized hardware to support diverse operational requirements across the turbine fleet.

The DS3800HXPE1A1A is deployed in GE Frame 5, 6, and 7 gas turbines to expand the I/O capacity of the main microprocessor boards. In these applications, the board provides additional analog and digital interfaces for exhaust temperature monitoring systems, combustion dynamics instrumentation, and fuel system position feedback. The EEPROM sockets store turbine-specific fuel curves and startup sequences optimized for different ambient conditions or fuel qualities. During commissioning, engineers configure the jumpers to match the specific frame and application, enabling standardized hardware to support diverse operational requirements across the turbine fleet.

Steam Turbine Retrofit and Modernization:

In steam turbine applications within paper mills and petrochemical facilities, this board facilitates the integration of modern sensors and control elements into legacy Mark IV systems. The expander provides the I/O points necessary to add digital valve positioners, upgraded vibration monitoring, or advanced process sensors without replacing the entire control system. The firmware flexibility allows implementation of improved control algorithms—such as advanced steam temperature control or adaptive speed governing—while retaining the proven Mark IV hardware platform, extending the operational life of existing turbine assets.

In steam turbine applications within paper mills and petrochemical facilities, this board facilitates the integration of modern sensors and control elements into legacy Mark IV systems. The expander provides the I/O points necessary to add digital valve positioners, upgraded vibration monitoring, or advanced process sensors without replacing the entire control system. The firmware flexibility allows implementation of improved control algorithms—such as advanced steam temperature control or adaptive speed governing—while retaining the proven Mark IV hardware platform, extending the operational life of existing turbine assets.

Aeroderivative Turbine Package Integration:

For LM6000 and LM2500 units, the board supports the compact, high-density packaging requirements of aeroderivative control systems. It expands the CPU capability to handle the fast-acting control sequences required for peaking power applications, including rapid startup sequencing and load-following algorithms. The board’s shock and vibration ratings accommodate the higher-frequency vibration environments typical of aeroderivative packages mounted on offshore platforms or mobile power units, while the EEPROM storage enables quick configuration changes when units are relocated between sites with different grid requirements or operational protocols.

For LM6000 and LM2500 units, the board supports the compact, high-density packaging requirements of aeroderivative control systems. It expands the CPU capability to handle the fast-acting control sequences required for peaking power applications, including rapid startup sequencing and load-following algorithms. The board’s shock and vibration ratings accommodate the higher-frequency vibration environments typical of aeroderivative packages mounted on offshore platforms or mobile power units, while the EEPROM storage enables quick configuration changes when units are relocated between sites with different grid requirements or operational protocols.

Auxiliary System Control Centers:

The board finds application in auxiliary control panels managing turbine support systems such as lube oil skids, hydraulic power units, and cooling water systems. By expanding the main CPU’s I/O capability, it allows distributed control of these auxiliaries while maintaining centralized monitoring through the Mark IV operator interface. The hardware jumpers configure the board for specific auxiliary functions—such as pump sequencing logic or heat exchanger control—allowing standardized expander boards to be deployed across different auxiliary systems within the same plant, simplifying spare parts management and maintenance training.

The board finds application in auxiliary control panels managing turbine support systems such as lube oil skids, hydraulic power units, and cooling water systems. By expanding the main CPU’s I/O capability, it allows distributed control of these auxiliaries while maintaining centralized monitoring through the Mark IV operator interface. The hardware jumpers configure the board for specific auxiliary functions—such as pump sequencing logic or heat exchanger control—allowing standardized expander boards to be deployed across different auxiliary systems within the same plant, simplifying spare parts management and maintenance training.

Safety Instrumented Systems (SIS) Expansion:

Within the Mark IV’s integrated control and protection architecture, this board provides additional I/O capacity for safety instrumented functions. It supports expansion of protective trip inputs, safety valve controls, and emergency shutdown sequences while maintaining the TMR redundancy required for Safety Integrity Level (SIL) compliance. The board’s deterministic response ensures that safety functions execute within specified timeframes, while the EEPROM storage retains safety configuration data through power cycles, supporting reliable operation of turbine protection systems in critical power generation applications.

Within the Mark IV’s integrated control and protection architecture, this board provides additional I/O capacity for safety instrumented functions. It supports expansion of protective trip inputs, safety valve controls, and emergency shutdown sequences while maintaining the TMR redundancy required for Safety Integrity Level (SIL) compliance. The board’s deterministic response ensures that safety functions execute within specified timeframes, while the EEPROM storage retains safety configuration data through power cycles, supporting reliable operation of turbine protection systems in critical power generation applications.