Description

DS3800HUMA1B1B: Product Overview

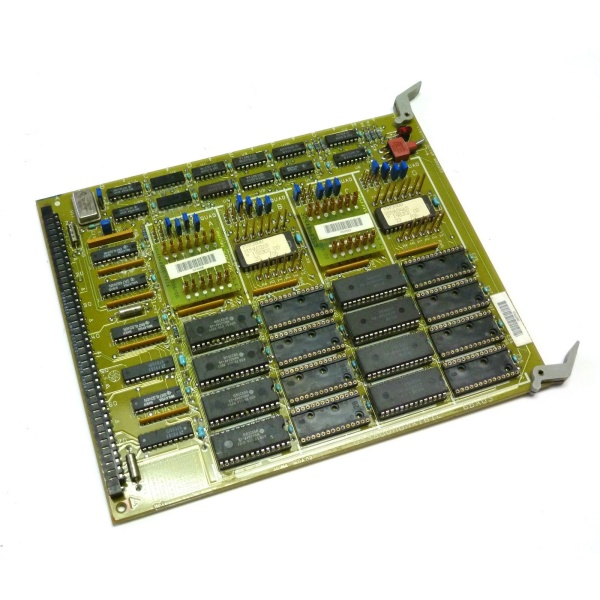

The DS3800HUMA1B1B functions as a universal memory storage module within GE’s Speedtronic Mark IV turbine control architecture. Positioned within the control rack assembly, this board provides the non-volatile memory infrastructure necessary to store critical control software, turbine configuration parameters, historical operational data, and real-time system variables. In the Mark IV’s triple modular redundant (TMR) system, this board operates within each redundant channel, ensuring that control algorithms and setpoints remain available even during power cycling or system restarts.

As a dedicated memory board, the unit employs Erasable Programmable Read-Only Memory (EPROM) technology to maintain data persistence without battery backup. These memory devices store the executable code for control sequences, fuel scheduling maps, protection logic algorithms, and communication protocols essential for turbine operation. The board interfaces with the Mark IV’s microprocessor modules through the high-speed backplane, providing rapid data retrieval for real-time control loops while maintaining data integrity across the industrial temperature ranges typical of power generation environments.

This board belongs to the DS3800 series of the Mark IV platform, a control system deployed across heavy-duty gas turbines (Frame 3, 5, 6, 7, 9) and LM aeroderivative units. The platform’s distributed architecture requires that each control channel maintain identical memory configurations to ensure synchronous operation during voting and redundancy management. The board’s universal design allows it to accommodate various memory capacities and configurations through hardware jumper settings, supporting diverse turbine models and application codes without requiring separate board variants.

DS3800HUMA1B1B: Technical Specifications

-

Model Number: DS3800HUMA1B1B

-

Manufacturer: General Electric

-

Product Type: Universal Memory Board

-

Series: GE Speedtronic Mark IV

-

Memory Technology: EPROM (Erasable Programmable Read-Only Memory)

-

Memory Organization: Quad-based architecture (Quads A, B, C, D with specific logical divisions)

-

Configuration Method: Hardware jumpers (10+ jumpers for memory mapping and logical configuration)

-

User Interface: 1 reset toggle switch, 1 red status LED

-

Backplane Interface: High-density modular connector with retention levers

-

Physical Dimensions: 8.25 cm × 4.15 cm

-

Operating Temperature: -35°C to +65°C

-

Storage Temperature: -40°C to +85°C

-

Humidity: 5% to 95% non-condensing

-

Mounting: Standard Mark IV rack slot with locking retention levers

-

Power Supply: Derived from Mark IV rack backplane (24-125 VDC system dependent)

-

Data Retention: Non-volatile (no battery required for memory retention)

GE DS3800HUMA1B1B

Part 4: Core Features & Customer Value

Non-Volatile Data Persistence for Control Security: The EPROM-based memory architecture ensures that critical turbine control algorithms, protection setpoints, and operational configurations remain intact during power outages or system shutdowns. Unlike volatile memory requiring constant power or battery-backed systems prone to failure, this board retains data indefinitely without maintenance. For power plant operators, this eliminates the risk of control system amnesia during extended outages and removes the maintenance burden of battery replacement schedules, ensuring that restart procedures proceed without time-consuming reconfiguration or data reloading.

Hardware-Based Configuration Flexibility: The onboard jumper matrix allows qualified technicians to configure memory addressing, logical divisions (Quads), and operational parameters without software tools or programming equipment. This hardware-level configurability supports different turbine models and application codes within the same physical board, reducing spare parts inventory requirements. During commissioning or retrofit projects, engineers can adapt the board to specific site requirements through simple jumper repositioning, facilitating faster startup and reducing the need for model-specific spares.

Diagnostic Visibility and Field Reset Capability: The integrated red LED indicator provides immediate visual confirmation of board status, while the reset toggle switch enables manual memory reinitialization during troubleshooting procedures. These features allow field technicians to perform basic diagnostics and recovery actions without specialized test equipment or laptop connections. When integrated with the Mark IV’s diagnostic software, the board supports comprehensive memory verification routines that detect bit errors or EPROM degradation before they impact turbine operation, enabling predictive maintenance and reducing forced outage risks.

Robust Physical Design for Industrial Longevity: The board utilizes industrial-grade epoxy-sealed EPROM devices and passive components rated for extended temperature operation within turbine control enclosures. The high-density modular connector system ensures reliable backplane mating through retention levers that prevent vibration-induced loosening in environments subject to turbine harmonics. This mechanical stability is critical for maintaining signal integrity in the high-vibration environments typical of gas turbine installations, ensuring continuous data availability for protection and control functions.

Part 5: Typical Applications

Heavy-Duty Gas Turbine Control System Memory:

The DS3800HUMA1B1B is deployed in GE Frame 5, 6, and 7 gas turbine installations to store fuel control curves, startup sequences, and protective trip algorithms. In these applications, the board maintains the executable code for the Mark IV’s microprocessor-based control loops, including combustion monitoring parameters and emissions control maps. The non-volatile memory ensures that following a plant blackout or control system reboot, the turbine can return to operation without requiring manual reloading of control software, supporting rapid grid reconnection and minimizing outage durations.

The DS3800HUMA1B1B is deployed in GE Frame 5, 6, and 7 gas turbine installations to store fuel control curves, startup sequences, and protective trip algorithms. In these applications, the board maintains the executable code for the Mark IV’s microprocessor-based control loops, including combustion monitoring parameters and emissions control maps. The non-volatile memory ensures that following a plant blackout or control system reboot, the turbine can return to operation without requiring manual reloading of control software, supporting rapid grid reconnection and minimizing outage durations.

Aeroderivative Turbine Peaking Applications:

For LM6000 and LM2500 aeroderivative units used in peaking power plants, this board stores fast-start algorithms and load-following control strategies optimized for frequent cycling. The memory board’s ability to retain data through rapid power transitions supports the quick-start capabilities required for grid stability services. In mechanical drive applications such as natural gas pipeline compression, the board stores process-specific control parameters that optimize turbine performance for varying pipeline pressure conditions, ensuring efficient operation across the full range of ambient temperatures and fuel qualities.

For LM6000 and LM2500 aeroderivative units used in peaking power plants, this board stores fast-start algorithms and load-following control strategies optimized for frequent cycling. The memory board’s ability to retain data through rapid power transitions supports the quick-start capabilities required for grid stability services. In mechanical drive applications such as natural gas pipeline compression, the board stores process-specific control parameters that optimize turbine performance for varying pipeline pressure conditions, ensuring efficient operation across the full range of ambient temperatures and fuel qualities.

Steam Turbine Electro-Hydraulic Control Retrofits:

In steam turbine applications within paper mills and petrochemical facilities, the board provides memory resources for electro-hydraulic control (EHC) system upgrades. It stores valve characterization curves, governor control algorithms, and protection logic for legacy steam turbines retrofitted with Mark IV controls. The hardware configuration jumpers allow the same board to support different valve configurations (single valve vs. sequential valve operation) and turbine ratings, simplifying spare parts management for facilities with mixed turbine fleets.

In steam turbine applications within paper mills and petrochemical facilities, the board provides memory resources for electro-hydraulic control (EHC) system upgrades. It stores valve characterization curves, governor control algorithms, and protection logic for legacy steam turbines retrofitted with Mark IV controls. The hardware configuration jumpers allow the same board to support different valve configurations (single valve vs. sequential valve operation) and turbine ratings, simplifying spare parts management for facilities with mixed turbine fleets.

Safety Instrumented Systems (SIS) Data Storage:

Within the Mark IV’s integrated protection architecture, this board stores safety-critical parameters including overspeed trip setpoints, vibration alarm limits, and emergency shutdown sequences. For applications requiring Safety Integrity Level (SIL) compliance, the board’s non-volatile memory ensures that safety configurations cannot be altered by transient electrical disturbances or software faults. The redundant memory configuration across TMR channels supports the high availability requirements of turbine protection systems, ensuring that safety functions remain operable even during single-channel maintenance activities.

Within the Mark IV’s integrated protection architecture, this board stores safety-critical parameters including overspeed trip setpoints, vibration alarm limits, and emergency shutdown sequences. For applications requiring Safety Integrity Level (SIL) compliance, the board’s non-volatile memory ensures that safety configurations cannot be altered by transient electrical disturbances or software faults. The redundant memory configuration across TMR channels supports the high availability requirements of turbine protection systems, ensuring that safety functions remain operable even during single-channel maintenance activities.