Description

DS3800HSDD1E1E: Product Overview

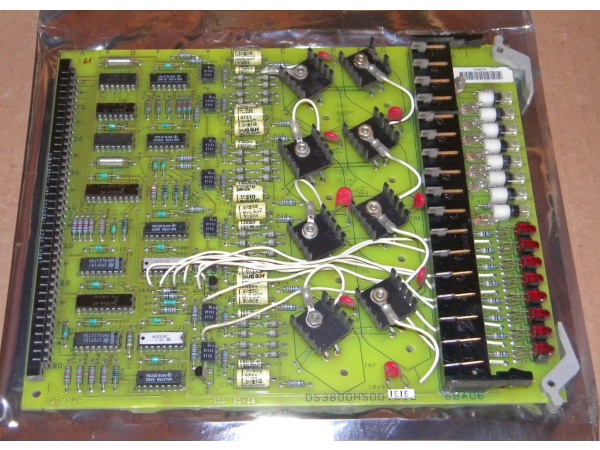

This board occupies a 6BA Euro-card slot in GE Mark IV turbine and EX2000 exciter control racks, serving as a high-speed data highway between the central processor and distributed I/O. It buffers address/data lines from the NDIA bus, converts 5 V CMOS levels to differential signals for remote transmission, and isolates the CPU from ground loops and switching transients originating in field wiring. The E1E revision includes timing refinements for improved compatibility with later-generation I/O pods and extended cable runs.

This board occupies a 6BA Euro-card slot in GE Mark IV turbine and EX2000 exciter control racks, serving as a high-speed data highway between the central processor and distributed I/O. It buffers address/data lines from the NDIA bus, converts 5 V CMOS levels to differential signals for remote transmission, and isolates the CPU from ground loops and switching transients originating in field wiring. The E1E revision includes timing refinements for improved compatibility with later-generation I/O pods and extended cable runs.

The epoxy-sealed construction makes this a line-replaceable module—internal faults require complete card swap rather than field repair. The module hot-swaps when the rack is powered down, and its low profile allows adjacent-slot population without additional cooling. As part of the DS3800 family, it benefits from the Mark IV platform’s deterministic 2 ms control interval and extensive installed base in power generation applications.

DS3800HSDD1E1E: Technical Specifications

-

Model Number: DS3800HSDD1E1E

-

Manufacturer: General Electric (GE Fanuc)

-

Product Type: High-Speed Data Distribution / Signal Buffer Board

-

Series: DS3800, Mark IV Speedtronic

-

Form Factor: 6BA Euro-card (≈ 233 × 160 mm)

-

Back-Plane Connector: Dual 40-pin header (J1/J2)

-

Logic Levels: 5 V CMOS/TTL (CPU side); differential LVDS (field side)

-

Data Rate: Up to 25 MHz (E1E enhanced speed)

-

Skew Tolerance: <1 ns channel-to-channel

-

Isolation: 1500 Vdc field-to-logic; opto-coupled control lines

-

Cable Length: Up to 15 m shielded twisted-pair to remote I/O

-

Power Demand: +5 V @ 1.2 A, +3.3 V @ 0.5 A from rack 2PL bus

-

Operating Temperature: 0 – 60 °C

-

Weight: ≈ 0.22 kg

-

Construction: Epoxy-sealed copper traces—non-repairable

DS3800HSDD1E1E

Core Features & Customer Value

Enhanced Data Rate: The E1E revision supports 25 MHz operation—25% faster than earlier D-series revisions. For control engineers, this enables higher I/O density or faster scan rates without bus saturation, providing headroom for future system expansion.

Precision Timing Control: The <1 ns skew specification ensures simultaneous sampling across distributed channels. For turbine protection applications, this means accurate phase correlation between exhaust temperature thermocouples, preventing false temperature imbalance trips during transient conditions.

Epoxy-Sealed Construction: All internal copper is encapsulated in high-temperature epoxy. In coastal or industrial environments with conductive dust and high humidity, this prevents trace-to-trace shorting that would cause random “DATA FAULT” alarms after ten-plus years. The trade-off is non-repairability—internal faults require whole-card exchange—but this is offset by reduced troubleshooting time and single-spare stocking rather than maintaining a repair bench.

Typical Applications

In combined-cycle power plants, this board installs in the Mark IV turbine control core where it distributes high-speed data to remote I/O pods monitoring exhaust temperatures, compressor discharge pressure, and generator outputs. The 25 MHz capability supports the dense thermocouple arrays common in modern F-class turbines.

On utility-scale EX2000 static exciters, the same card links the CPU to bridge-interface cards in the high-voltage cubicle. The extended 15-meter cable capability eliminates fiber-optic converters in many installations, reducing cost and complexity while maintaining noise immunity.

Mechanical-drive gas compressors in pipeline stations frequently use this part number for split-rack configurations where the CPU resides in the control room and I/O pods mount on the compressor skid. The enhanced timing margins tolerate the electrical noise and temperature extremes of these installations.