Description

DS3800HSAA1U1M: Product Overview

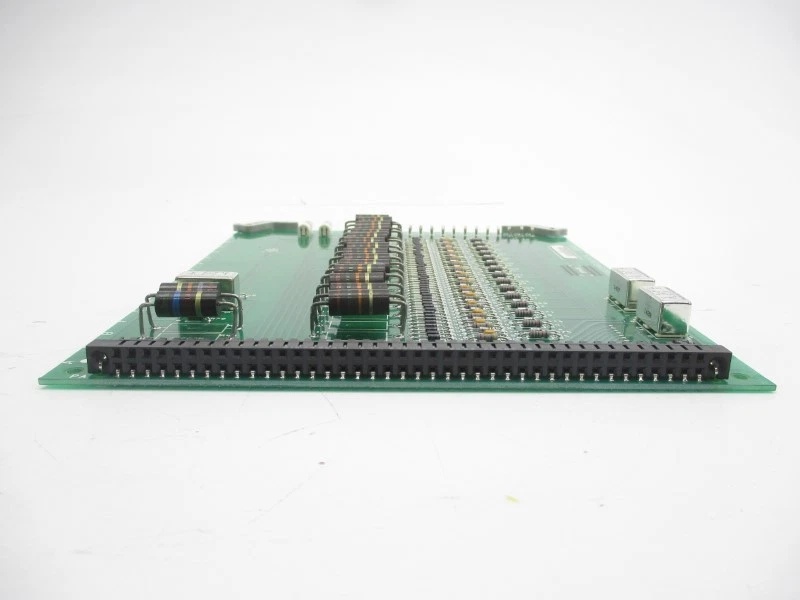

The DS3800HSAA1U1M serves as a critical servo amplification module within GE’s Speedtronic Mark IV turbine control architecture. Positioned within the drive control section of the system, this board receives low-level command signals from the main processor and converts them into precise current outputs capable of driving hydraulic servo valves. These servo valves, in turn, regulate fuel flow, steam admission, or variable geometry positioning in gas and steam turbine applications.

The board integrates an analog-to-digital converter (ADC) that processes position feedback signals from linear variable differential transformers (LVDTs) or similar position sensors. This closed-loop feedback mechanism enables the Mark IV system to maintain tight control over valve positioning with response times measured in milliseconds—essential for load following and frequency regulation in power generation environments. The DOM-PLUS designation indicates this board supports advanced diagnostic capabilities and enhanced signal processing algorithms compared to earlier DOM-series implementations.

As a member of the DS3800 series, the HSAA1U1M leverages the modular architecture that made the Mark IV system dominant in heavy-duty turbine applications throughout the 1980s and 1990s. The series standardized on a common card frame and connector system, allowing rapid replacement and minimizing spare parts inventory. The board’s design reflects GE’s field-hardened approach: conservative component derating, conformal coating for moisture protection, and mechanical retention features that withstand decades of thermal cycling and vibration in power plant environments.

GE DS3800HISA1A1A

DS3800HSAA1U1M: Technical Specifications

-

Model Number: DS3800HSAA1U1M

-

Manufacturer: General Electric

-

Product Type: DOM-PLUS Servo Amplifier Board

-

System Compatibility: Speedtronic Mark IV Turbine Control

-

Primary Connector: 34-pin ribbon cable interface with retention levers

-

Memory Interface: Socketed EEPROM module for calibration data storage

-

Signal Conditioning: 3 onboard trimmer resistors for gain/offset adjustment

-

Conversion Capability: Integrated analog-to-digital converter (ADC)

-

Thermal Management: Integrated heatsink assembly with directed airflow design

-

Mounting: Standard DS3800 series card cage with retention levers

-

Weight: Approximately 0.65 lbs (0.29 kg)

-

Operating Environment: Designed for industrial control room environments with forced air cooling

Core Features & Customer Value

Precision Control with Field-Proven Reliability: The DOM-PLUS architecture incorporates redundant signal paths and self-diagnostic routines that continuously monitor servo loop health. For plant operators, this translates to fewer false trips and the ability to detect valve drift before it impacts turbine performance. The board’s conservative design margins mean it continues operating within specification even as components age—a critical consideration for baseload power plants where unexpected outages carry severe economic penalties.

Maintainable Design for Long Service Life: The socketed EEPROM allows complete calibration data transfer to a replacement board without recalibration procedures, reducing mean time to repair (MTTR) from hours to minutes. The three trimmer resistors enable field technicians to fine-tune servo response characteristics without removing the board from service. This maintainability was revolutionary when introduced and remains a benchmark for modern control system retrofits.

Thermal Engineering for Harsh Environments: The integrated heatsink and specific airflow requirements (bottom intake, top exhaust) reflect lessons learned from early turbine control failures. By mandating proper ribbon cable routing to preserve cooling paths, GE ensured the board’s semiconductor junction temperatures remain within safe operating areas even when installed in crowded card cages with ambient temperatures exceeding 50°C. This thermal discipline directly correlates with the 20+ year service lives commonly observed in field installations.

GE DS3800HISA1A1A

Typical Applications

The DS3800HSAA1U1M is deployed in gas turbine fuel valve control systems, where it drives the hydraulic servo valves regulating natural gas or distillate fuel flow to combustion chambers. In a typical Frame 7 or Frame 9 heavy-duty gas turbine, multiple HSAA boards operate in parallel—each controlling a separate fuel valve quadrant to ensure even combustion temperature distribution and prevent hot spots that degrade turbine life.

In steam turbine applications, this board controls admission valves that regulate high-pressure steam flow from boilers to turbine cylinders. The precise positioning capability (typically ±0.1% accuracy) enables sliding pressure operation and advanced load control strategies that improve heat rate efficiency. Combined-cycle plants particularly benefit from the board’s fast response during load transients when switching between gas turbine exhaust heat recovery and duct firing modes.

The module also finds application in turbine variable geometry control, driving servo mechanisms that adjust inlet guide vanes, compressor stator stages, or exhaust diffuser angles. These functions require the board’s ADC to process multiple LVDT feedback signals and calculate optimal positioning schedules based on ambient conditions and operating points—functionality that predates modern digital valve controllers but remains operational in numerous installed bases worldwide.