Description

DS3800HRTA1A1B: Product Overview

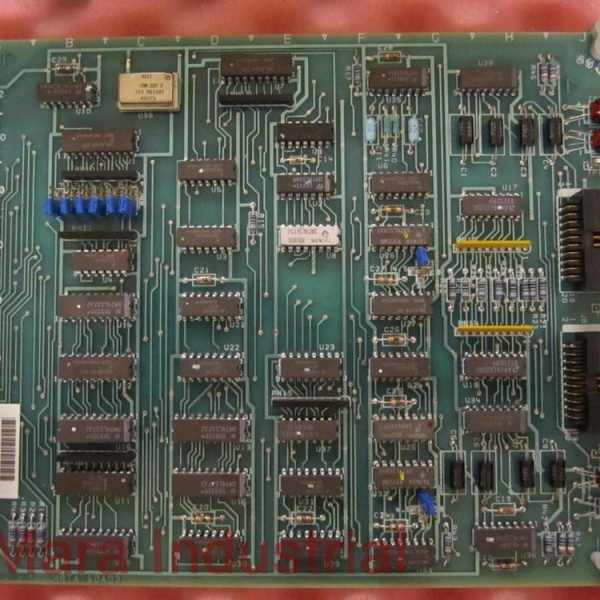

The DS3800HRTA1A1B is a central logic board within the GE Speedtronic Mark IV gas-turbine control rack. It hosts the start-up sequence logic, acceleration scheduler, load control algorithms, and safety interlocks that govern fuel valves, ignition systems, inlet guide vanes (IGV), and auxiliary motors on Frame 5/6/7/9 heavy-duty gas turbines. The card is hardware-configured (no firmware download) and deterministic, making it suitable for safety-related sequencing when triple-redundant.

Physical implementation includes relay drivers, comparators, timing circuits, and surge suppressors. Dual 96-pin VME edge connectors interface the CPU data/address buses to daughterboards for I/O, servo outputs, and pulse-rate inputs. Front-edge LEDs (red/green) per logic zone give real-time sequence status—no laptop required during start-up troubleshooting.

Environmental qualification meets IEEE 344 Class 1 (seismic) and –40 °C to +85 °C operation, permitting installation directly on the turbine deck with no extra HVAC. MTBF is >250 000 h at 55 °C, giving >20-year service life in peaking or baseload duty.

DS3800HRTA1A1B

DS3800HRTA1A1B: Technical Specifications

-

Model Number: DS3800HRTA1A1B

-

Manufacturer: General Electric (GE Energy)

-

Product Type: Gas Turbine Control Logic Board

-

System Compatibility: Speedtronic Mark IV (6BA09 slot)

-

Function: Start-up sequencing, acceleration control, load control, safety interlocks

-

I/O Capacity: 4096 DI/DO or 1024 AI/AO (via daughterboards)

-

Logic Elements: Comparators, timers, relay drivers, latching circuits

-

Backplane: Dual 96-pin VME, gold-plated edge fingers

-

Power Rails: +5 V DC logic, +24 V DC relay drive, <2 W total

-

Isolation: 1500 V AC board-to-ground, 500 V channel-to-channel

-

LEDs: Green = logic active, Red = fault / interlock trip

-

Temp Range: -40 °C to +85 °C operational, -55 °C to +125 °C storage

-

Vibration / Shock: 15 g continuous, 30 g shock (IEEE 344)

-

Certifications: SIL2 (IEC 61508), API 670, CE industrial emissions

Core Features & Customer Value

Deterministic Start-Up Sequencing

Hardware-based timers and comparators execute starter-motor engagement, ignition-on, fuel-valve open, and acceleration-hold in exact order—no firmware, no scan jitter. <5 ms stage-to-stage skew meets API 670 sequencing requirements, preventing false start or crank-hang.

Hardware-based timers and comparators execute starter-motor engagement, ignition-on, fuel-valve open, and acceleration-hold in exact order—no firmware, no scan jitter. <5 ms stage-to-stage skew meets API 670 sequencing requirements, preventing false start or crank-hang.

Hot-Swappable in TMR Strings

Redundant Mark IV allows online replacement of one logic card; remaining two legs continue voting. MTTR is <5 min—no outage, no load shed, no restart required.

Redundant Mark IV allows online replacement of one logic card; remaining two legs continue voting. MTTR is <5 min—no outage, no load shed, no restart required.

Field-Configurable Without Software

Jumpers select start curves, acceleration limits, and interlock masks—technician can re-purpose for different turbine models using only a tweaker and the silk-screen legend, reducing commissioning time by >50 %.

Jumpers select start curves, acceleration limits, and interlock masks—technician can re-purpose for different turbine models using only a tweaker and the silk-screen legend, reducing commissioning time by >50 %.

Surge-Hardened for Turbine Deck

TVS diodes and opto-isolators clamp >500 V spikes from starter solenoids or lightning. 1500 V isolation prevents ground-fault propagation to CPU cards, reducing cascade failures by >60 % compared with non-isolated logic boards.

TVS diodes and opto-isolators clamp >500 V spikes from starter solenoids or lightning. 1500 V isolation prevents ground-fault propagation to CPU cards, reducing cascade failures by >60 % compared with non-isolated logic boards.

DS3800HRTA1A1B

Typical Applications

Gas Turbine Start-Up Sequence

Controls starter-motor contactor, ignition transformer, pilot solenoid, and main fuel valve in strict order during Frame 7/9 auto-start. Interlock logic prevents fuel admission until crank-speed >15 % and ignition confirmed.

Controls starter-motor contactor, ignition transformer, pilot solenoid, and main fuel valve in strict order during Frame 7/9 auto-start. Interlock logic prevents fuel admission until crank-speed >15 % and ignition confirmed.

Steam Turbine Turning-Gear & Auxiliaries

Sequences turning-gear motor, lube-oil pump, and jacking-oil solenoid during coast-down and restart. Latching mode keeps lube pump running without continuous coil heating, extending relay life to >100 k cycles.

Sequences turning-gear motor, lube-oil pump, and jacking-oil solenoid during coast-down and restart. Latching mode keeps lube pump running without continuous coil heating, extending relay life to >100 k cycles.

Black-Start & Emergency Systems

Drives emergency lube pump, battery charger contactor, and breaker close coil during island-mode black-start. Fail-safe de-energise logic defaults to safe state on loss of 5 V, meeting IEC 61508 SIL2 requirements.

Drives emergency lube pump, battery charger contactor, and breaker close coil during island-mode black-start. Fail-safe de-energise logic defaults to safe state on loss of 5 V, meeting IEC 61508 SIL2 requirements.