Description

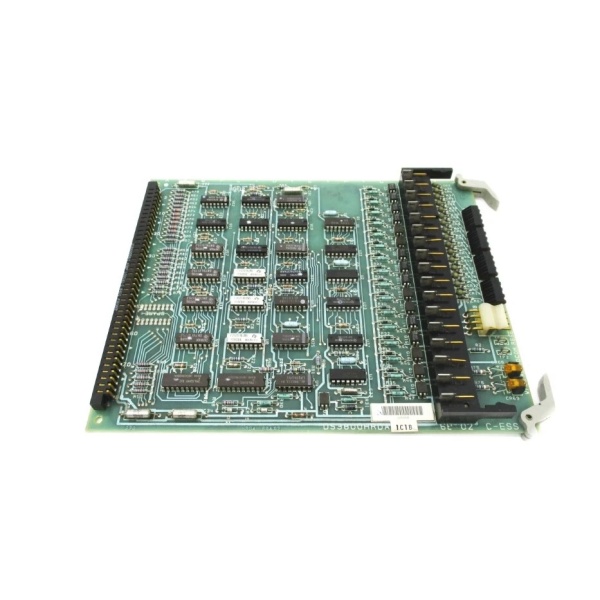

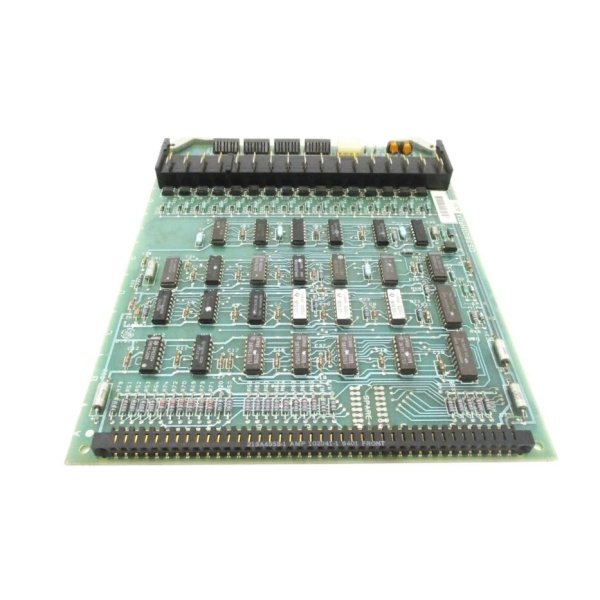

DS3800HRDA1C1B: Product Overview

The DS3800HRDA1C1B functions as a critical signal interface module within GE’s Speedtronic Mark IV turbine control architecture. Positioned between field-mounted sensors and the system’s central processors, this board performs essential buffering and decoding operations that ensure reliable data transmission across the control network. The “HRD” designation identifies this as a high-speed receiver/decoder module optimized for the demanding signal processing requirements of heavy-duty gas and steam turbine applications.

The board incorporates multiple memory sockets housing EPROM and EEPROM devices that store operational firmware and configurable parameters. These memory elements enable the board to execute decoding algorithms that translate raw sensor signals into digital formats compatible with the Mark IV’s triple-modular-redundant (TMR) processing architecture. The buffered outputs maintain signal integrity over the extended cable runs typical of power generation facilities, where control cabinets may be located hundreds of feet from turbine-mounted instrumentation.

As a member of the DS3800 series, the HRDA1C1B adheres to the standardized form factor and connector scheme that GE established for the Mark IV platform. This standardization allows rapid field replacement and minimizes spare parts inventory requirements for facilities maintaining legacy turbine control systems. The board’s design reflects the industrial control philosophy of the 1980s and 1990s: extensive use of socketed components for field serviceability, conservative electrical design margins, and robust mechanical retention features that withstand decades of thermal cycling and vibration in power plant environments.

GE DS3800HRDA1C1B

DS3800HRDA1C1B: Technical Specifications

-

Model Number: DS3800HRDA1C1B

-

Manufacturer: General Electric

-

Product Type: Buffer Decoder Board

-

System Compatibility: Speedtronic Mark IV Turbine Control

-

Memory Configuration: Multiple EPROM and EEPROM sockets (approximately 30 devices)

-

Memory Types: EPROM (erasable programmable read-only memory), EEPROM (electrically erasable programmable read-only memory)

-

Programming: EPROM contains fixed operational firmware; EEPROM stores configurable parameters

-

Diagnostic Indicators: Multiple LED indicators (red, yellow, clear/orange, grey, green, blue)

-

Backplane Interface: Ribbon cable connectors with retention hardware

-

Connector Types: Male and female docking connectors of varying sizes

-

Mounting: Standard DS3800 series card cage with retention clips and screws

-

Component Count: Approximately 80 resistors with color-coded power ratings

-

Operating Environment: Industrial control room, forced air cooling recommended

-

Weight: Approximately 0.5 lbs (0.23 kg)

Core Features & Customer Value

Flexible Memory Architecture for Operational Adaptability: The board’s combination of EPROM and EEPROM devices provides both stable operational firmware and field-configurable parameters. The EPROM contains the core decoding algorithms that remain fixed throughout the board’s service life, ensuring consistent behavior. The EEPROM, in contrast, allows technicians to adjust timing parameters, scaling factors, and diagnostic thresholds without hardware changes. For maintenance teams, this means the ability to optimize board performance for specific turbine configurations or update operational characteristics as plant requirements evolve, all without returning the board to the manufacturer.

Comprehensive Diagnostic Visibility: The DS3800HRDA1C1B incorporates an extensive array of LED indicators that provide real-time visibility into board operational status. The red LEDs typically indicate power status and critical faults, while the multicolored diode array (clear/orange, grey, green, blue) offers granular visibility into data processing states, communication handshake status, and memory access activity. For field engineers troubleshooting intermittent issues, this visual feedback eliminates the need for specialized test equipment in many cases, allowing rapid identification of failed channels or communication errors during routine inspections.

Field-Serviceable Design for Maximum Uptime: The board’s construction emphasizes maintainability through socketed components and standardized connectors. The “SPARE” socket locations allow installation of additional memory devices for expanded functionality or diagnostic purposes. The ribbon cable connectors feature positive retention mechanisms that prevent loosening under vibration, while the extractor clips enable safe removal from crowded card cages without adjacent board disturbance. This serviceability translates directly to reduced mean time to repair (MTTR)—a critical metric for baseload power plants where unplanned outages carry severe economic penalties.

GE DS3800HRDA1C1B

Typical Applications

The DS3800HRDA1C1B is deployed in gas turbine control signal distribution systems, where it buffers and decodes signals from speed sensors, temperature transmitters, and pressure transducers before transmission to the Mark IV’s main processors. In a typical Frame 7 or Frame 9 heavy-duty gas turbine, multiple HRD boards operate in conjunction—each handling specific sensor groups that feed the system’s voting logic. The board’s buffering capability prevents signal degradation when driving multiple loads or traversing long cable distances between the turbine deck and control room.

In steam turbine supervisory instrumentation networks, this board processes signals from proximity probes monitoring shaft vibration, eccentricity detectors, and phase reference sensors. These measurements are critical for detecting rotor instabilities, bearing wear, and thermal misalignment conditions that could lead to forced outages. The HRDA1C1B’s decoding functions translate the analog sensor outputs into digital representations that the Mark IV’s protective algorithms can evaluate against trip setpoints measured in thousandths of an inch or degrees of phase angle.

The module also finds application in turbine auxiliary system control, buffering signals from lube oil system pressure switches, cooling water flow transmitters, and fuel gas valve position indicators. In these applications, the board’s ability to handle both analog and discrete signal types through configurable firmware proves valuable, allowing standardized hardware to serve diverse functions across the turbine island. The EEPROM-stored configuration parameters enable rapid repurposing of spare boards for different signal types during maintenance emergencies.