Description

DS3800HPLA1A1B: Product Overview

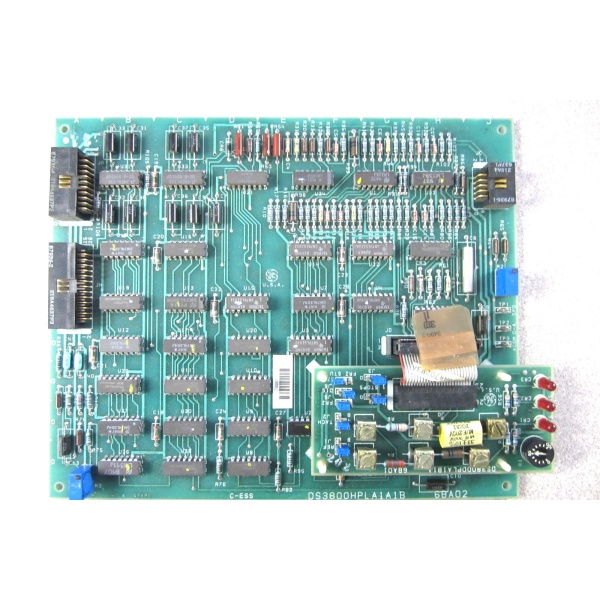

The board serves as a panel interface logic module within GE’s Speedtronic Mark IV turbine control architecture. Positioned within the control rack assembly, this unit functions as the critical bridge between the centralized control processors and the operator interface panels located at the turbine control console. In the Mark IV’s triple modular redundant (TMR) system, this board operates within each independent control channel, ensuring that operator commands are received reliably and that status information is displayed accurately across redundant processing paths.

As a panel interface board, the unit manages the bidirectional data flow between the Mark IV core logic and external operator interfaces. It processes keypad inputs, switch selections, and command entries from the operator panel, translating these human inputs into control system commands. Simultaneously, it receives operational status, alarm conditions, and turbine data from the central processors and formats this information for display on operator panels, annunciators, and indicator lights. The board’s logic circuitry handles the electrical interface requirements, signal conditioning, and protocol translation necessary for reliable communication over the panel cabling.

The board features robust construction designed for continuous operation in industrial control room environments. It incorporates EPROM-based firmware that defines the specific panel interface protocol and operational characteristics for different turbine applications. Diagnostic LEDs provide immediate visual confirmation of communication status, power integrity, and fault conditions without requiring diagnostic software connections.

This board belongs to the DS3800 series of the Mark IV platform, deployed across heavy-duty gas turbines (Frame 3, 5, 6, 7, 9) and LM aeroderivative units. The platform’s distributed architecture allows the panel interface to operate autonomously while maintaining deterministic synchronization with the core control processors, ensuring that operator commands are executed with the appropriate priority and safety interlocks.

DS3800HPLA1A1B: Technical Specifications

-

Model Number: DS3800HPLA1A1B

-

Manufacturer: General Electric

-

Product Type: Panel Interface Board

-

Series: GE Speedtronic Mark IV

-

Architecture: Triple Modular Redundant (TMR) compatible

-

Interface Function: Operator panel and HMI data exchange

-

Logic Circuits: TTL/CMOS integrated circuits for signal processing and protocol handling

-

Memory: EPROM sockets for panel interface firmware and configuration

-

Status Indication: Diagnostic LEDs for communication and power status

-

Panel Connection: Dual interface connectors for operator panel cabling

-

Backplane Interface: High-density modular connector (AMD 218A4553-1 compatible)

-

Configuration: Hardware jumpers for panel type and addressing

-

Operating Temperature: -40°C to +70°C (industrial grade)

-

Storage Temperature: -40°C to +85°C

-

Humidity: 5% to 95% non-condensing

-

Vibration/Shock: 5 g vibration / 50 g shock (per Mark IV specifications)

-

Mounting: Standard Mark IV rack slot with integrated retention levers

-

Power Supply: Derived from Mark IV rack backplane (+5 VDC logic)

GE DS3800HPLA1A1B

Part 4: Core Features & Customer Value

Reliable Operator Interface Data Exchange: The board ensures that operator commands from control panel keypads, switches, and entry devices are reliably transmitted to the Mark IV control processors, even in electrically noisy industrial environments. By providing dedicated interface logic with signal conditioning and noise filtering, the board prevents data corruption or missed commands that could result from direct connection of panel wiring to sensitive processor inputs. For control room operators, this translates to responsive, predictable interaction with the turbine control system during critical startup, loading, and shutdown operations.

Dedicated Panel Protocol Management: The board handles the specific communication protocols required by GE operator interface panels, managing timing, handshaking, and data formatting that would otherwise burden the main control processors. This protocol isolation ensures that panel communication failures or electrical faults cannot disrupt critical turbine control functions. For system integrators, this dedicated interface architecture allows panel upgrades or modifications without requiring changes to core control software, facilitating technology updates while maintaining proven control logic.

Comprehensive Diagnostic Visibility: Integrated diagnostic LEDs provide immediate indication of communication link status, power integrity, and board operational state. During commissioning or troubleshooting, technicians can verify that the panel interface is communicating with the central processors, that data is flowing bidirectionally, and that the board has initialized correctly. This visibility reduces mean time to repair by allowing rapid identification of whether faults originate in the panel cabling, interface board, or central processors.

Robust Industrial Design for Control Room Environments: The board utilizes industrial-grade integrated circuits and passive components rated for extended temperature operation and the electrical stresses encountered in turbine control applications. The retention lever system ensures reliable backplane engagement, while the modular connector design supports hot-swappable replacement in TMR configurations. Given the critical nature of operator interface availability, this construction reliability ensures continuous control room operation without unexpected interface failures.

Flexible Configuration for Diverse Panel Types: Hardware jumpers and EPROM-based firmware allow the same physical board to support different operator panel configurations—ranging from simple indicator/annunciator panels to complex keypad/display units—without hardware modifications. This flexibility reduces spare parts inventory requirements for facilities with multiple turbine types, as the board can be configured for specific panel protocols through firmware and jumper settings rather than requiring model-specific variants.

Part 5: Typical Applications

Gas Turbine Control Room Interface:

The DS3800HPLA1A1B is deployed in GE Frame 5, 6, and 7 gas turbine installations to interface between the Mark IV control rack and the operator control panel (OCP). In these applications, the board processes Start, Stop, Reset, and Load commands entered via control panel pushbuttons, ensuring these critical operator inputs are reliably transmitted to the control logic with appropriate priority. It also drives status indicators on the panel, displaying turbine speed, temperature conditions, and alarm states to operators. The board’s redundant configuration ensures that operator interface functionality remains available even during single-channel maintenance activities.

The DS3800HPLA1A1B is deployed in GE Frame 5, 6, and 7 gas turbine installations to interface between the Mark IV control rack and the operator control panel (OCP). In these applications, the board processes Start, Stop, Reset, and Load commands entered via control panel pushbuttons, ensuring these critical operator inputs are reliably transmitted to the control logic with appropriate priority. It also drives status indicators on the panel, displaying turbine speed, temperature conditions, and alarm states to operators. The board’s redundant configuration ensures that operator interface functionality remains available even during single-channel maintenance activities.

Steam Turbine Operator Station Interface:

In steam turbine applications within power plants and industrial facilities, this board manages communication with distributed operator stations and local control panels. It handles the interface for manual valve control stations, allowing operators to stroke steam admission valves during maintenance or emergency procedures. The board also manages alarm annunciation interfaces, ensuring that critical protective trips are immediately visible to operators through panel-mounted annunciators and indicator lights.

In steam turbine applications within power plants and industrial facilities, this board manages communication with distributed operator stations and local control panels. It handles the interface for manual valve control stations, allowing operators to stroke steam admission valves during maintenance or emergency procedures. The board also manages alarm annunciation interfaces, ensuring that critical protective trips are immediately visible to operators through panel-mounted annunciators and indicator lights.

Aeroderivative Turbine Package Interface:

For LM6000 and LM2500 units, the board interfaces with compact operator panels typically located in acoustically enclosed packages or remote skids. It manages the reduced wiring distances and specific panel configurations common to aeroderivative installations, ensuring reliable operator interface despite the higher-frequency vibration environments and space constraints of these applications. The board supports both local panel operation and remote interface capabilities for unmanned or lightly staffed installations.

For LM6000 and LM2500 units, the board interfaces with compact operator panels typically located in acoustically enclosed packages or remote skids. It manages the reduced wiring distances and specific panel configurations common to aeroderivative installations, ensuring reliable operator interface despite the higher-frequency vibration environments and space constraints of these applications. The board supports both local panel operation and remote interface capabilities for unmanned or lightly staffed installations.

Protection System Interface Panels:

Within the Mark IV’s protection system architecture, this board interfaces with dedicated protection panels that display overspeed, vibration, and safety system status. It ensures that protective system arming status, trip conditions, and diagnostic information are clearly presented to operators and protection engineers. The deterministic response of the panel interface ensures that alarm conditions are displayed without delay, supporting rapid operator response to emergency situations.

Within the Mark IV’s protection system architecture, this board interfaces with dedicated protection panels that display overspeed, vibration, and safety system status. It ensures that protective system arming status, trip conditions, and diagnostic information are clearly presented to operators and protection engineers. The deterministic response of the panel interface ensures that alarm conditions are displayed without delay, supporting rapid operator response to emergency situations.