Description

DS3800HMPK1L1K: Product Overview

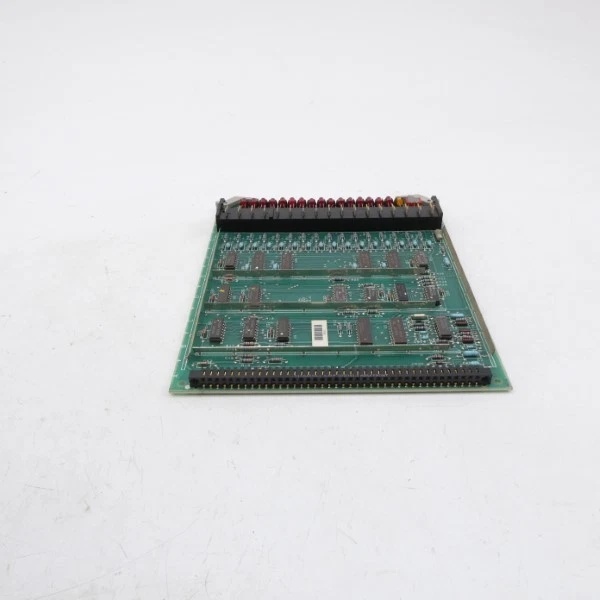

The DS3800HMPK1L1K serves as the central intelligence module within GE’s Speedtronic Mark IV turbine control architecture. Positioned as the primary processing unit in the control cabinet, this board executes the complex algorithms that govern turbine startup, shutdown, speed control, temperature limiting, and protective tripping functions. It receives conditioned input signals from various I/O boards throughout the system, performs computational operations according to embedded control strategies, and generates output commands that regulate fuel valves, guide vanes, and auxiliary systems.

The board incorporates a dedicated microprocessor supported by multiple memory devices including EPROM modules containing fixed operational firmware and EEPROM for configurable parameters. This memory architecture enables the board to execute deterministic control loops with cycle times measured in milliseconds—a critical requirement for maintaining turbine stability during load transients and grid disturbances. The dual 50-pin ribbon cable connectors interface with adjacent I/O boards, while the 34-pin connector provides backplane connectivity for power and system-level communication.

As a member of the DS3800 series, the HMPK1L1K adheres to the standardized form factor established for the Mark IV platform. This standardization allows rapid field replacement and reduces spare parts inventory requirements for facilities maintaining legacy turbine control systems. The Mark IV represented GE’s first implementation of triple-modular-redundant (TMR) architecture for turbine control, where three identical microprocessor boards operate in parallel, with their outputs voted to ensure continued operation even in the presence of single-point failures. This redundancy level was revolutionary when introduced in the 1980s and established the safety benchmark for critical rotating machinery protection.

DS3800HLIA1A1B

DS3800HMPK1L1K: Technical Specifications

-

Model Number: DS3800HMPK1L1K

-

Manufacturer: General Electric

-

Product Type: Microprocessor Board

-

System Compatibility: Speedtronic Mark IV Turbine Control

-

Processing Architecture: Microprocessor-based controller

-

Memory Configuration: Multiple EPROM and EEPROM sockets

-

Firmware Storage: EPROM modules (erasable programmable read-only memory)

-

Parameter Storage: EEPROM (electrically erasable programmable read-only memory)

-

Backplane Interface: 34-pin ribbon cable connector

-

I/O Interfaces: Dual 50-pin ribbon cable connectors

-

Status Indicators: 3 red LEDs and 1 amber LED (front-visible)

-

Power Requirements: +5 VDC

-

Thermal Management: Requires adequate airflow to prevent microprocessor overheating

-

Mounting: Standard DS3800 series card cage with retention levers

-

Operating Environment: Industrial control room with forced air cooling

-

Weight: Approximately 0.5 lbs (0.23 kg)

Core Features & Customer Value

Deterministic Control for Turbine Stability: The microprocessor architecture executes control algorithms with consistent, predictable timing essential for closed-loop turbine regulation. Speed control loops, temperature limiting functions, and acceleration schedules all require precise computational timing to prevent instability or overshoot. For plant operators, this deterministic behavior translates to smooth turbine startups, stable load following, and reliable protection against overspeed or overtemperature conditions that could cause catastrophic mechanical damage.

Modular Memory Architecture for Operational Flexibility: The separation between EPROM firmware and EEPROM parameters allows control strategies to remain fixed while operational characteristics are adjusted for specific turbine configurations. Site-specific parameters such as fuel curves, temperature limits, and alarm setpoints reside in EEPROM, enabling field customization without firmware changes. When replacement becomes necessary, transferring the EEPROM to a spare board preserves all site-specific tuning, eliminating the need for post-replacement recommissioning and reducing mean time to repair (MTTR).

Visual Diagnostic Capability: The four front-mounted LEDs (three red, one amber) provide immediate visual indication of board operational status, memory access activity, and fault conditions. For field technicians troubleshooting intermittent issues, these indicators offer a first-line diagnostic tool without requiring specialized test equipment or software interfaces. The LED patterns can indicate power status, processor activity, memory faults, or communication errors, enabling rapid identification of failed boards in a TMR configuration.

Thermal Design Considerations: The microprocessor generates significant heat during operation, and the board layout positions heat-sensitive ribbon cable connectors adjacent to the processor. Proper installation practices—ensuring adequate room-temperature airflow, avoiding crowded equipment rooms, and routing cables to prevent blocking cooling paths—are essential for long-term reliability. This thermal awareness, while requiring attention during installation, ensures the board achieves the 20+ year service lives typical of Mark IV installations when properly maintained.

DS3800HLIA1A1B

Typical Applications

The DS3800HMPK1L1K is deployed as the central controller in gas turbine generator sets, where it executes the startup sequence, acceleration control, synchronization logic, and load regulation algorithms. In a typical Frame 6, Frame 7, or Frame 9 heavy-duty gas turbine, three HMP boards operate in TMR configuration, each processing identical input data and executing the same control algorithms. Their outputs are voted before driving fuel valves and other final control elements, ensuring that a single board failure cannot cause an unsafe condition or unnecessary trip.

In steam turbine applications, this board manages admission valve control, extraction pressure regulation, and generator load control. The microprocessor calculates optimal valve positions based on load demand, throttle pressure, and temperature constraints, adjusting outputs to maintain stable grid frequency while maximizing thermal efficiency. The board’s protection algorithms monitor critical parameters such as bearing vibration, eccentricity, and differential expansion, initiating controlled shutdown sequences if safe operating limits are approached.

The module also serves in mechanical drive applications for compressors, pumps, and other rotating equipment, where it provides speed control, process variable regulation, and equipment protection. In pipeline compressor stations, the HMP board coordinates anti-surge control algorithms that prevent destructive compressor instability, adjusting guide vanes and recycle valves in response to changing flow conditions and gas composition.