Description

DS3800HLIA1B1D: Product Overview

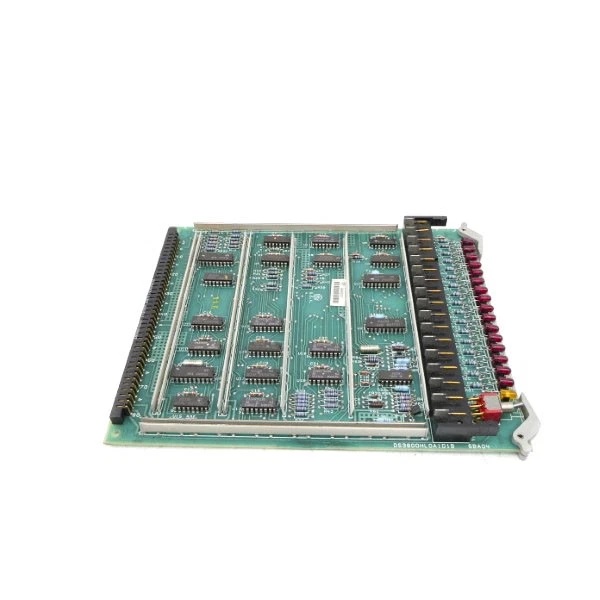

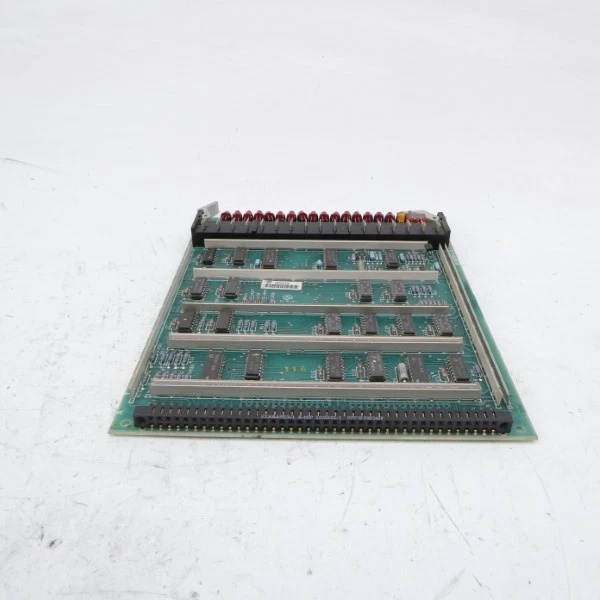

The board serves as a logic input interface and status indication module within the Speedtronic Mark IV turbine control architecture. Positioned within the control rack assembly, this unit receives discrete logic signals from auxiliary control systems and provides comprehensive visual indication of input states through an array of front-panel LEDs. In the Mark IV’s triple modular redundant (TMR) system, this board operates within each independent control channel, offering technicians immediate visual confirmation of input activity without requiring diagnostic software connections.

As a logic input board, the unit functions as part of the auxiliary input chain, processing status signals from field devices, interlocks, and control switches. It bridges the electrical interface between field wiring and the central microprocessor complex, conditioning discrete inputs for compatibility with the Mark IV’s logic levels. The prominent amber LED illuminates when the board receives power and successfully completes startup diagnostics, while the fifteen red LEDs provide circuit-by-circuit indication of input activity, allowing rapid identification of active signals and operational states.

The board features a modular connector on one end that interfaces with the high-density Mark IV backplane, ensuring reliable signal transmission and power distribution. Retention levers on the front edge facilitate secure mechanical mounting and provide the necessary extraction force for hot-swappable maintenance procedures. The component layout positions the LEDs between the retention levers, making them clearly visible to operators and maintenance personnel during normal operation.

This board belongs to the DS3800 series of the Mark IV platform, deployed across heavy-duty gas turbines (Frame 3, 5, 6, 7, 9) and LM aeroderivative units. The platform’s distributed architecture allows this input interface to operate as a discrete status monitoring point while maintaining deterministic data exchange with the central control processors, ensuring that auxiliary system states are accurately captured and displayed in real-time.

GE DS3800HLOA1D1B

DS3800HLIA1B1D: Technical Specifications

-

Model Number: DS3800HLIA1B1D

-

Manufacturer: General Electric

-

Product Type: Logic Input Board

-

Series: GE Speedtronic Mark IV

-

Architecture: Triple Modular Redundant (TMR) compatible

-

Form Factor: 6BA02 standard Mark IV board format

-

Indicator LEDs: 16 total—15 red (input status) + 1 amber (power/diagnostic)

-

LED Visibility: Front-facing, positioned between retention levers

-

Input Function: Logic level input interface for auxiliary control signals

-

Backplane Interface: Modular connector (AMD 218A4553-1 compatible)

-

Mounting: Retention levers for secure rack installation

-

Operating Temperature: -40°C to +70°C (industrial grade)

-

Storage Temperature: -40°C to +85°C

-

Humidity: 5% to 95% non-condensing

-

Vibration/Shock: 5 g vibration / 50 g shock (per Mark IV specifications)

-

Power Supply: Derived from Mark IV rack backplane

Part 4: Core Features & Customer Value

Comprehensive Visual Diagnostics:

The sixteen-element LED array provides immediate, at-a-glance status indication of board health and input activity. The amber power indicator confirms that the board is energized and has passed initialization self-tests, while each red LED corresponds to a specific input circuit, illuminating when signal activity is present. For field technicians, this eliminates the need for multimeter probing or laptop connections to verify input states during troubleshooting, significantly reducing mean time to repair during critical outages.

The sixteen-element LED array provides immediate, at-a-glance status indication of board health and input activity. The amber power indicator confirms that the board is energized and has passed initialization self-tests, while each red LED corresponds to a specific input circuit, illuminating when signal activity is present. For field technicians, this eliminates the need for multimeter probing or laptop connections to verify input states during troubleshooting, significantly reducing mean time to repair during critical outages.

Robust Mechanical Retention:

The integrated retention levers provide positive mechanical engagement with the rack backplane, ensuring reliable electrical contact despite the vibration environment typical of turbine control enclosures. These levers also serve as extraction handles, allowing technicians to remove and replace the board without tools during maintenance procedures. The secure mounting prevents fretting corrosion on connector pins—a common failure mode in high-vibration industrial environments—and ensures consistent signal integrity over years of operation.

The integrated retention levers provide positive mechanical engagement with the rack backplane, ensuring reliable electrical contact despite the vibration environment typical of turbine control enclosures. These levers also serve as extraction handles, allowing technicians to remove and replace the board without tools during maintenance procedures. The secure mounting prevents fretting corrosion on connector pins—a common failure mode in high-vibration industrial environments—and ensures consistent signal integrity over years of operation.

Hot-Swappable Maintenance Design:

The board supports replacement within the Mark IV TMR architecture, allowing technicians to restore input monitoring capabilities without turbine shutdown. The modular connector system facilitates rapid exchange, while the retention levers ensure proper seating force when reinstalling. This maintainability is essential for auxiliary input functions where continued monitoring is required for safe turbine operation, ensuring that redundant channels maintain input visibility even when one channel is being serviced.

The board supports replacement within the Mark IV TMR architecture, allowing technicians to restore input monitoring capabilities without turbine shutdown. The modular connector system facilitates rapid exchange, while the retention levers ensure proper seating force when reinstalling. This maintainability is essential for auxiliary input functions where continued monitoring is required for safe turbine operation, ensuring that redundant channels maintain input visibility even when one channel is being serviced.

Standardized Interface Compatibility:

The board utilizes the standard Mark IV modular connector and 6BA02 form factor, ensuring physical and electrical compatibility with the existing control rack infrastructure. This standardization allows the board to be installed in any available slot within the Mark IV architecture without modifications, simplifying spare parts management and system expansion. The consistent form factor also ensures that airflows and thermal management within the control cabinet remain optimized.

The board utilizes the standard Mark IV modular connector and 6BA02 form factor, ensuring physical and electrical compatibility with the existing control rack infrastructure. This standardization allows the board to be installed in any available slot within the Mark IV architecture without modifications, simplifying spare parts management and system expansion. The consistent form factor also ensures that airflows and thermal management within the control cabinet remain optimized.

Passive Diagnostic Capability:

Unlike boards that require active communication with the main processor to report status, the LED indicators operate independently of software polling, providing immediate indication even if communication paths are temporarily disrupted. This passive visibility allows technicians to distinguish between input circuit failures and communication faults—a critical distinction during troubleshooting that prevents unnecessary replacement of field wiring when the issue is actually upstream in the data path.

Unlike boards that require active communication with the main processor to report status, the LED indicators operate independently of software polling, providing immediate indication even if communication paths are temporarily disrupted. This passive visibility allows technicians to distinguish between input circuit failures and communication faults—a critical distinction during troubleshooting that prevents unnecessary replacement of field wiring when the issue is actually upstream in the data path.

GE DS3800HLOA1D1B

Part 5: Typical Applications

Gas Turbine Auxiliary Status Monitoring:

The board is deployed in GE Frame 5, 6, and 7 gas turbines to monitor discrete logic inputs from auxiliary systems such as lube oil pressure switches, cooling fan status contacts, and fuel valve limit switches. In these applications, the fifteen red LEDs provide circuit-specific indication of which auxiliary devices are active, allowing operators to verify proper sequencing during turbine startup. For example, technicians can confirm that the lube oil pressure switch has closed (LED illuminated) before the turbine is permitted to roll, ensuring mechanical protection without referencing diagnostic software.

The board is deployed in GE Frame 5, 6, and 7 gas turbines to monitor discrete logic inputs from auxiliary systems such as lube oil pressure switches, cooling fan status contacts, and fuel valve limit switches. In these applications, the fifteen red LEDs provide circuit-specific indication of which auxiliary devices are active, allowing operators to verify proper sequencing during turbine startup. For example, technicians can confirm that the lube oil pressure switch has closed (LED illuminated) before the turbine is permitted to roll, ensuring mechanical protection without referencing diagnostic software.

Control Cabinet Power and Status Indication:

Within the Mark IV control cabinet, the board serves as a local status indicator for various internal logic states and interlock conditions. It monitors signals such as cabinet door switches, cooling fan proof-of-flow, and internal power supply status. The amber LED provides immediate confirmation that the specific control channel is powered and operational, while the red LEDs indicate active states of internal control logic. This local indication is particularly valuable during commissioning and maintenance when technicians are working within the cabinet and cannot view the main operator interface.

Within the Mark IV control cabinet, the board serves as a local status indicator for various internal logic states and interlock conditions. It monitors signals such as cabinet door switches, cooling fan proof-of-flow, and internal power supply status. The amber LED provides immediate confirmation that the specific control channel is powered and operational, while the red LEDs indicate active states of internal control logic. This local indication is particularly valuable during commissioning and maintenance when technicians are working within the cabinet and cannot view the main operator interface.

Steam Turbine Retrofit Interface:

In steam turbine modernization projects, this board provides the discrete input interface for legacy auxiliary equipment being integrated with new Mark IV controls. It monitors the status of existing pressure switches, temperature switches, and limit devices that utilize simple contact closures. The LED indication allows calibration and verification of these inputs during commissioning without requiring connection to the central HMI, speeding up the process of matching old field wiring to new control logic and ensuring that all auxiliary interlocks are properly captured.

In steam turbine modernization projects, this board provides the discrete input interface for legacy auxiliary equipment being integrated with new Mark IV controls. It monitors the status of existing pressure switches, temperature switches, and limit devices that utilize simple contact closures. The LED indication allows calibration and verification of these inputs during commissioning without requiring connection to the central HMI, speeding up the process of matching old field wiring to new control logic and ensuring that all auxiliary interlocks are properly captured.

Aeroderivative Package Logic Monitoring:

For LM6000 and LM2500 units, the board monitors the compact, high-density logic inputs typical of aeroderivative packages, including inlet guide vane position switches, fuel staging valve status, and compartment ventilation damper positions. The visible LED indicators are particularly valuable in these applications where control cabinets may be located in noisy or cramped environments, allowing technicians to verify input states at a glance without disconnecting communications cables to connect programming devices.

For LM6000 and LM2500 units, the board monitors the compact, high-density logic inputs typical of aeroderivative packages, including inlet guide vane position switches, fuel staging valve status, and compartment ventilation damper positions. The visible LED indicators are particularly valuable in these applications where control cabinets may be located in noisy or cramped environments, allowing technicians to verify input states at a glance without disconnecting communications cables to connect programming devices.

Emergency and Safety System Inputs:

Within the Mark IV’s protection architecture, this board provides input status indication for safety-critical signals such as emergency stop contacts, fire suppression system status, and hazardous gas detection alarms. The immediate LED indication ensures that maintenance personnel can verify the state of these protective inputs during testing and inspection, confirming that safety systems are properly armed and that input circuits are intact without relying solely on software indications that could be affected by communication failures.

Within the Mark IV’s protection architecture, this board provides input status indication for safety-critical signals such as emergency stop contacts, fire suppression system status, and hazardous gas detection alarms. The immediate LED indication ensures that maintenance personnel can verify the state of these protective inputs during testing and inspection, confirming that safety systems are properly armed and that input circuits are intact without relying solely on software indications that could be affected by communication failures.