Description

DS3800HLCA1E1E Product Overview

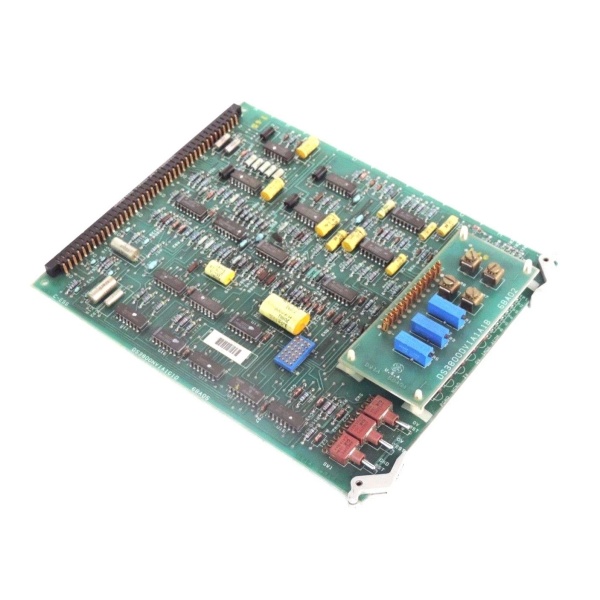

The DS3800HLCA1E1E is a high-level control and I/O interface printed-circuit board that resides in GE Mark IV Speedtronic gas- and steam-turbine control cubicles. Occupying a single 6U VME-style slot, the card acts as a programmable interface between the turbine-control microprocessor and field devices such as fuel-valve positioners, inlet-guide-vane actuators, and auxiliary motor contactors.

The DS3800HLCA1E1E is a high-level control and I/O interface printed-circuit board that resides in GE Mark IV Speedtronic gas- and steam-turbine control cubicles. Occupying a single 6U VME-style slot, the card acts as a programmable interface between the turbine-control microprocessor and field devices such as fuel-valve positioners, inlet-guide-vane actuators, and auxiliary motor contactors.

Within the automation hierarchy it sits at the “field I/O & sequencing” layer: it receives low-level commands from the CPU, applies on-board logic stored in EPROM, drives outputs through buffered drivers, and returns status bits (including BIT results) over the backplane. Transformer-isolated power rails and ceramic metal-film resistors give the card enough noise immunity to survive the ground-shift events common when 4 kV breakers close inside the turbine hall.

The board belongs to the DS3800 “HLCA” family of Mark IV personality boards—cards that share the same 96-pin edge connector and mounting rails but implement dedicated control or sequencing tasks. This common hardware platform lets sites stock one spare chassis and populate it with the exact personality boards required for each turbine section .

GE DS3800NMSM1G1E

Technical Specifications

-

Model Number: DS3800HLCA1E1E

-

Manufacturer: General Electric

-

Product Type: High-Level Control / I/O Interface Board

-

Control Inputs: Three adjustable jumper blocks for logic-level selection

-

User Interface: Test & Reset toggle switches (0.4 A rated), red BIT LED

-

Memory: On-board EPROM firmware, DIP switch pack for option selection

-

Test Access: 12 labelled test-point pins (TP1-TP12) for differential probe access

-

Edge Connector: 218A4553-1 female AMD connector, short-edge mount

-

Passives: Three resistor networks, four trim potentiometers, ceramic metal-film resistors

-

Power Rails: +5 V logic, ±12 V analog, +24 V field derived from Mark IV backplane

-

Temperature Range: 0 … +70 °C operating, -40 … +85 °C storage

-

Form Factor: 6U single-slot VME64 slave, alignment marks A-J plus triangle index

-

Weight: ≈ 0.4 kg (0.9 lb) with heat-sink bar

Core Features & Customer Value

Test/Reset toggles – Front-panel switches let technicians exercise outputs or reset logic without software tools, shortening commissioning time when the HMI is not yet online.

Test/Reset toggles – Front-panel switches let technicians exercise outputs or reset logic without software tools, shortening commissioning time when the HMI is not yet online.

EPROM firmware – Control sequencing is stored in socketed EPROM, so site-specific fuel curves or start-up ramps can be updated by simply swapping a chip—no laptop or download cable required.

12 test points – Labelled TP pins allow direct oscilloscope access to critical waveforms (servo demand, feedback, BIT flags), making it easy to verify timing or diagnose intermittent faults without removing the card.

Three jumper blocks – Logic-level and function options are set with jumpers rather than DIP switches, providing positive engagement and vibration immunity inside the turbine cubicle.

Drop-in spare – Shares the DS3800 form factor and alignment marks with earlier HLCA revisions; no mounting changes, no calibration, and no parameter downloads required during swap-out .

GE DS3800NMSM1G1E

Typical Applications

In combined-cycle power plants the DS3800HLCA1E1E is installed in the “sequencing” bay of every Mark IV panel that governs gas turbines. It handles fuel-valve position loops, inlet-guide-vane scheduling, and auxiliary motor start/stop logic while reporting BIT status to the operator station.

In combined-cycle power plants the DS3800HLCA1E1E is installed in the “sequencing” bay of every Mark IV panel that governs gas turbines. It handles fuel-valve position loops, inlet-guide-vane scheduling, and auxiliary motor start/stop logic while reporting BIT status to the operator station.

In pipeline compressor stations the same card sequences the starting means (diesel or electric motor) and manages the anti-surge valve position loop, ensuring the centrifugal compressor stays clear of the surge line during rapid transients.

Because the card stores its logic in EPROM, it is also used in safety-related nuclear standby turbine-generator sets where “simple device” classification avoids additional software V&V.