Description

DS3800HLCA1D1E: Product Overview

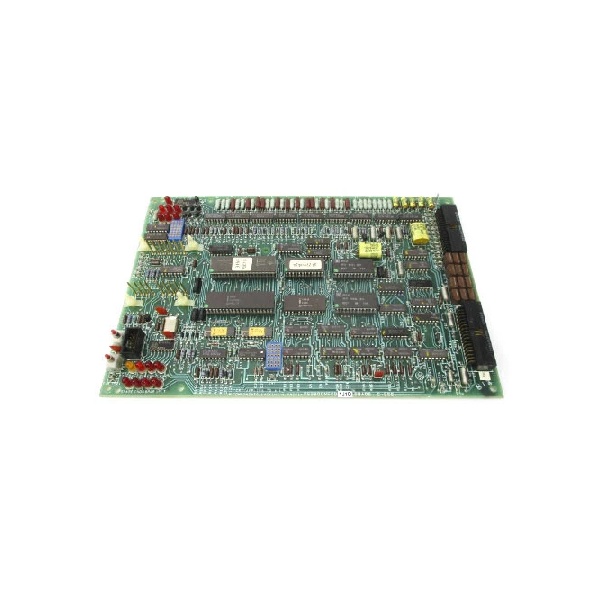

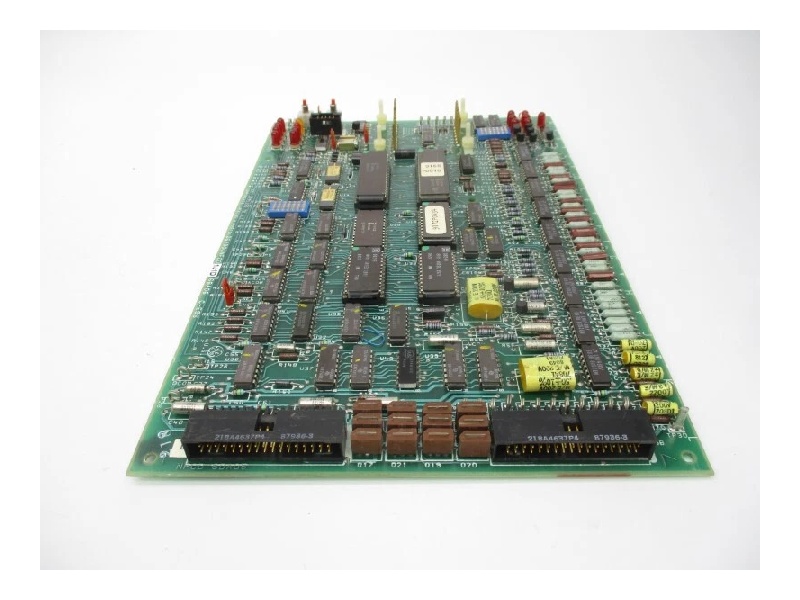

The DS3800HLCA1D1E functions as a critical I/O control interface within GE’s Speedtronic Mark IV turbine management platform. Positioned between field termination assemblies and the main processor modules, this board serves as a signal conditioning and distribution layer for gas and steam turbine control systems. In the Mark IV architecture, the board operates within a triple modular redundant (TMR) framework, where three identical control channels process data simultaneously to ensure fault tolerance and continuous operation during single-point failures.

The board handles high-level analog and discrete signals originating from turbine sensors, auxiliary equipment, and safety systems. It processes these inputs through integrated programmable interface circuits, DIP switches, and EPROM-based configuration memory, translating raw field data into standardized logic levels compatible with the Mark IV’s microprocessor-based control algorithms. Four onboard potentiometers enable field calibration of analog signal ranges, while three resistor networks provide voltage division and impedance matching for precise control loop stability.

As a member of the DS3800 series, the board benefits from the Mark IV’s proven architecture, which has been deployed extensively in heavy-duty gas turbines (Frame 3, 5, 6, 7, 9) and LM aeroderivative units. The platform’s distributed multiprocessor design allows individual I/O boards to operate autonomously while maintaining synchronization with the central control processors. This modularity enables online diagnostics, card-level fault isolation, and hot-swappable maintenance capabilities that minimize forced outage risks in continuous-process applications.

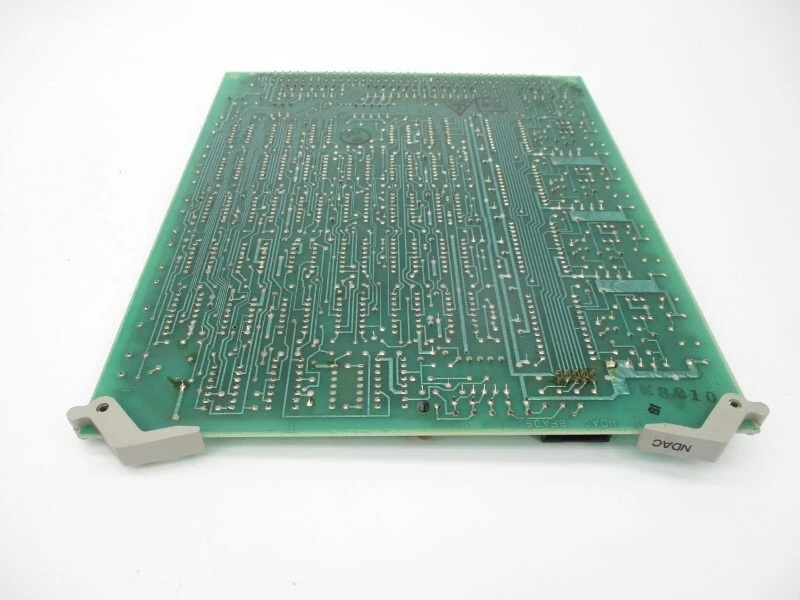

DS3800NDAC1B1C

DS3800HLCA1D1E: Technical Specifications

-

Model Number: DS3800HLCA1D1E

-

Manufacturer: General Electric

-

Product Type: I/O Control Board / High Level Control Assembly

-

Series: GE Speedtronic Mark IV

-

Architecture: Triple Modular Redundant (TMR) compatible

-

Integrated Circuits: 35+ (including programmable interfaces, DIPs, EPROMs, oscillators)

-

Adjustable Components: 4 potentiometers (voltage calibration), 3 resistor networks (voltage division)

-

Test Points: 12 TP test points (located lower right corner)

-

Indicators: 1 red LED test light

-

Switches: 2 toggle switches (Test marked A4627P5, Reset marked A4627PII, 0.4 VA max), 3 configurable jumper switches

-

Connectors: 1 AMD 218A4553-1 high-density backplane connector

-

Mounting: Factory-drilled corner holes with alignment markings (A-J) on top edge

-

Passive Components: Ceramic metal film resistors, surface-mount capacitors

-

Operating Environment: Designed for NEMA 1/12/4 control cabinet installations with appropriate cooling

DS3800NDAC1B1C

Part 4: Core Features & Customer Value

Signal Conditioning Precision and Field Calibration Capability:

The inclusion of four front-accessible potentiometers and three resistor networks allows qualified technicians to trim analog signal ranges without removing the board from service. This field-calibration capability reduces maintenance windows and eliminates the need for spare boards pre-configured for specific sensor ranges. For engineers managing multiple turbine configurations, this adjustability translates to reduced spare parts inventory and faster loop commissioning during startup or retrofit projects.

The inclusion of four front-accessible potentiometers and three resistor networks allows qualified technicians to trim analog signal ranges without removing the board from service. This field-calibration capability reduces maintenance windows and eliminates the need for spare boards pre-configured for specific sensor ranges. For engineers managing multiple turbine configurations, this adjustability translates to reduced spare parts inventory and faster loop commissioning during startup or retrofit projects.

Comprehensive Diagnostics and Test Accessibility:

With twelve dedicated test points and integrated LED indicators, the board provides immediate visual and probe-accessible verification of signal integrity. Technicians can verify power supply levels, reference voltages, and digital logic states using standard test equipment without interrupting control system operation. This diagnostic transparency shortens troubleshooting time during alarm investigations or preventive maintenance cycles, directly reducing mean time to repair (MTTR) in critical power generation applications.

With twelve dedicated test points and integrated LED indicators, the board provides immediate visual and probe-accessible verification of signal integrity. Technicians can verify power supply levels, reference voltages, and digital logic states using standard test equipment without interrupting control system operation. This diagnostic transparency shortens troubleshooting time during alarm investigations or preventive maintenance cycles, directly reducing mean time to repair (MTTR) in critical power generation applications.

Robust Physical Design for Industrial Longevity:

The board utilizes ceramic metal film resistors and industrial-grade capacitors mounted on a rigid PCB with factory-installed stiffeners. The AMD 218A4553-1 connector system ensures reliable backplane mating through thousands of insertion cycles, while corner extraction clips facilitate safe removal during hot-swap procedures. For facility managers operating in harsh industrial environments, these construction features translate to extended operational life and reduced frequency of replacement, particularly important given the obsolete status of the Mark IV series and the criticality of maintaining operational spares.

The board utilizes ceramic metal film resistors and industrial-grade capacitors mounted on a rigid PCB with factory-installed stiffeners. The AMD 218A4553-1 connector system ensures reliable backplane mating through thousands of insertion cycles, while corner extraction clips facilitate safe removal during hot-swap procedures. For facility managers operating in harsh industrial environments, these construction features translate to extended operational life and reduced frequency of replacement, particularly important given the obsolete status of the Mark IV series and the criticality of maintaining operational spares.

Triple Modular Redundancy Integration:

Designed specifically for the Mark IV’s TMR architecture, the board supports the voting and diagnostic protocols necessary for fault-tolerant turbine control. Each I/O channel operates in parallel with two redundant counterparts, with the board’s circuitry enabling signal comparison and deviation detection. This architectural integration provides protection against both random hardware failures and systematic errors, ensuring that turbine protective functions remain available even during maintenance activities or transient electrical disturbances.

Designed specifically for the Mark IV’s TMR architecture, the board supports the voting and diagnostic protocols necessary for fault-tolerant turbine control. Each I/O channel operates in parallel with two redundant counterparts, with the board’s circuitry enabling signal comparison and deviation detection. This architectural integration provides protection against both random hardware failures and systematic errors, ensuring that turbine protective functions remain available even during maintenance activities or transient electrical disturbances.