Description

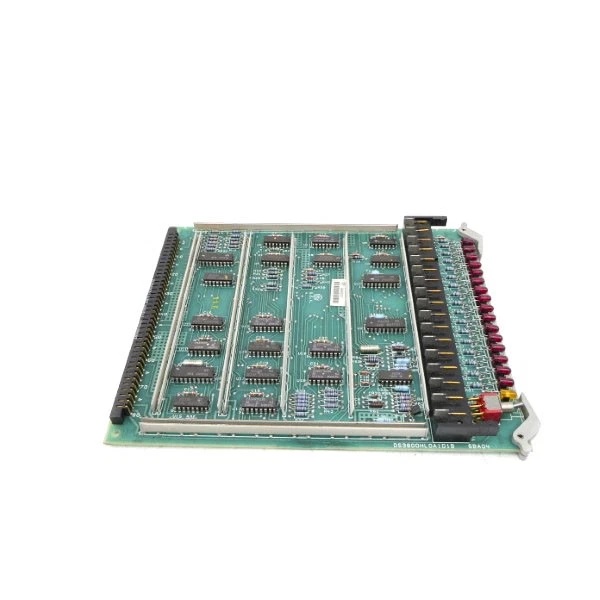

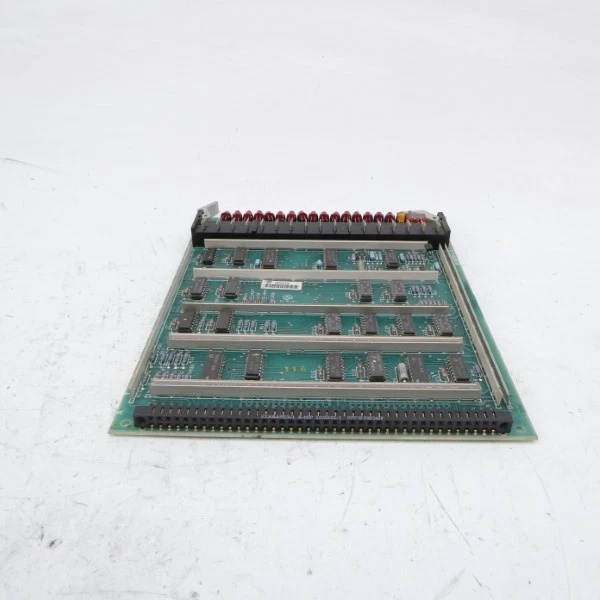

DS3800HL0A1D1B: Product Overview

The DS3800HL0A1D1B functions as a high-level logic and interface module within GE’s Speedtronic Mark IV turbine control architecture. Positioned within the control rack assembly, this board serves as a critical processing layer that bridges the gap between the system’s microprocessor-based control logic and the field-terminated input/output signals essential for turbine operation. In the Mark IV’s triple modular redundant (TMR) design, this board operates within one of three independent control channels, performing signal conditioning and logic translation necessary for fault-tolerant control.

As a member of the DS3800 “HL” (High Level) series, the board handles logic-level signal processing tasks that support the broader control strategy. It processes digital logic signals, provides buffering and isolation between circuit domains, and ensures that data exchanged between the central processors and peripheral I/O boards maintains integrity across the potentially noisy electrical environment of an industrial turbine control cabinet. The board’s circuitry typically includes transistor-transistor logic (TTL) or similar digital logic families optimized for the speed and reliability requirements of real-time turbine control.

This board belongs to the proven Mark IV platform, a microprocessor-based control system deployed across heavy-duty gas turbines (Frame 3, 5, 6, 7, 9) and LM aeroderivative units worldwide. The platform’s distributed architecture allows individual logic boards to operate autonomously while maintaining synchronization with redundant counterparts. This modularity enables online diagnostics and card-level replacement without requiring turbine shutdown, provided proper TMR maintenance procedures are followed.

GE DS3800HLOA1D1B

DS3800HL0A1D1B: Technical Specifications

-

Model Number: DS3800HL0A1D1B

-

Manufacturer: General Electric

-

Product Type: High Level Logic/Interface Board

-

Series: GE Speedtronic Mark IV

-

Architecture: Triple Modular Redundant (TMR) compatible

-

Logic Interface: Digital logic signal processing and buffering

-

Backplane Connection: High-density modular connector for rack integration

-

Status Indicators: LED indicators for power and operational status

-

Signal Conditioning: Logic level translation and noise filtering circuitry

-

Mounting: Standard Mark IV rack slot with retention hardware

-

Operating Temperature: -40°C to +70°C (industrial grade)

-

Humidity: 5% to 95% non-condensing

-

Passive Components: Industrial-grade resistors, capacitors, and ferrite EMI suppression elements

-

Circuit Protection: Transient voltage suppression and isolation barriers

Part 4: Core Features & Customer Value

Reliable Signal Processing in High-Noise Environments: The board provides robust logic-level signal conditioning that isolates sensitive microprocessor circuits from the electromagnetic interference common in turbine control enclosures. By buffering and filtering digital signals between the backplane and external interfaces, the board ensures that control commands and status feedback remain uncorrupted by electrical noise from variable frequency drives, ignition systems, and high-voltage switchgear. For control system engineers, this translates to consistent logic states and reduced susceptibility to false triggering or data corruption that could affect turbine protection schemes.

Support for Fault-Tolerant TMR Architecture: Designed specifically for integration into the Mark IV’s triple modular redundant system, the board operates in parallel with two redundant counterparts to ensure continuous availability. Each board processes data independently, with the system’s voting logic comparing outputs to detect and isolate faults. This architectural integration means that a failure of a single logic board does not compromise turbine control or protection, allowing maintenance to be performed during operation without forced outages. For plant managers, this redundancy design directly supports availability goals and reduces maintenance window constraints.

Field-Proven Industrial Durability: Constructed with industrial-grade components and rigid PCB mounting hardware, the board withstands the thermal cycling, vibration, and humidity conditions typical of power generation environments. The high-density backplane connector system ensures reliable electrical contact through thousands of insertion cycles, supporting hot-swappable maintenance procedures. This physical robustness translates to extended service life and reduced frequency of replacement, which is particularly valuable given the obsolete status of the Mark IV series and the criticality of maintaining operational spares for legacy turbine installations.

Modular Maintenance and Diagnostics: The board’s design supports the Mark IV diagnostic philosophy, with visible status indicators providing immediate visual confirmation of power and basic operational states. When integrated with the system’s diagnostic software, the board facilitates fault isolation to the card level, allowing technicians to identify and replace failed components quickly. This diagnostic transparency reduces mean time to repair (MTTR) and minimizes the risk of extended outages due to control system faults.

GE DS3800HLOA1D1B

Part 5: Typical Applications

Heavy-Duty Gas Turbine Control Systems:

The DS3800HL0A1D1B is deployed in GE Frame 5, 6, and 7 gas turbine installations to provide logic processing for control sequences and protective functions. In these applications, the board processes digital logic signals associated with fuel control valves, starter sequences, and protective trip logic. Working within the TMR architecture, it ensures that critical safety functions such as overspeed protection and overtemperature shutdowns remain active and reliable. The board’s signal conditioning capabilities are essential for maintaining the integrity of high-speed logic signals in environments where large motor starters and high-voltage ignition systems generate significant electrical noise.

The DS3800HL0A1D1B is deployed in GE Frame 5, 6, and 7 gas turbine installations to provide logic processing for control sequences and protective functions. In these applications, the board processes digital logic signals associated with fuel control valves, starter sequences, and protective trip logic. Working within the TMR architecture, it ensures that critical safety functions such as overspeed protection and overtemperature shutdowns remain active and reliable. The board’s signal conditioning capabilities are essential for maintaining the integrity of high-speed logic signals in environments where large motor starters and high-voltage ignition systems generate significant electrical noise.

Steam Turbine Electro-Hydraulic Control (EHC):

In steam turbine applications within paper mills, petrochemical facilities, and district heating plants, this board interfaces with hydraulic control systems and governor mechanisms. It processes discrete logic inputs from pressure switches, limit switches, and trip devices, providing the logic translation necessary for the Mark IV control algorithms to regulate steam admission valves. The board’s robust design ensures reliable operation despite the thermal and vibrational stresses present in steam turbine enclosures, supporting continuous process operations where unplanned outages carry significant economic penalties.

In steam turbine applications within paper mills, petrochemical facilities, and district heating plants, this board interfaces with hydraulic control systems and governor mechanisms. It processes discrete logic inputs from pressure switches, limit switches, and trip devices, providing the logic translation necessary for the Mark IV control algorithms to regulate steam admission valves. The board’s robust design ensures reliable operation despite the thermal and vibrational stresses present in steam turbine enclosures, supporting continuous process operations where unplanned outages carry significant economic penalties.

Aeroderivative Turbine Packages:

For LM6000 and LM2500 aeroderivative units used in peaking power plants and mechanical drive applications such as natural gas pipeline compression, the board provides the logic interface for fast-acting control sequences. These applications require rapid startup and load-following capabilities, demanding logic circuits that respond consistently within milliseconds. The board’s reliable signal processing ensures that emergency shutdown sequences execute promptly when triggered by protective systems, safeguarding high-value turbine equipment from damage during upset conditions.

For LM6000 and LM2500 aeroderivative units used in peaking power plants and mechanical drive applications such as natural gas pipeline compression, the board provides the logic interface for fast-acting control sequences. These applications require rapid startup and load-following capabilities, demanding logic circuits that respond consistently within milliseconds. The board’s reliable signal processing ensures that emergency shutdown sequences execute promptly when triggered by protective systems, safeguarding high-value turbine equipment from damage during upset conditions.

Safety Instrumented Systems (SIS) Integration:

Within the Mark IV’s integrated control and protection architecture, this logic board supports safety functions by processing signals associated with protective trip logic and voting algorithms. In applications requiring Safety Integrity Level (SIL) compliance, the board’s participation in the TMR voting scheme ensures that safety shutdown signals are reliably generated and transmitted to final control elements such as fuel trip valves. The fault-tolerant design ensures that no single point of failure can disable protective functions, supporting compliance with industrial safety standards.

Within the Mark IV’s integrated control and protection architecture, this logic board supports safety functions by processing signals associated with protective trip logic and voting algorithms. In applications requiring Safety Integrity Level (SIL) compliance, the board’s participation in the TMR voting scheme ensures that safety shutdown signals are reliably generated and transmitted to final control elements such as fuel trip valves. The fault-tolerant design ensures that no single point of failure can disable protective functions, supporting compliance with industrial safety standards.