Description

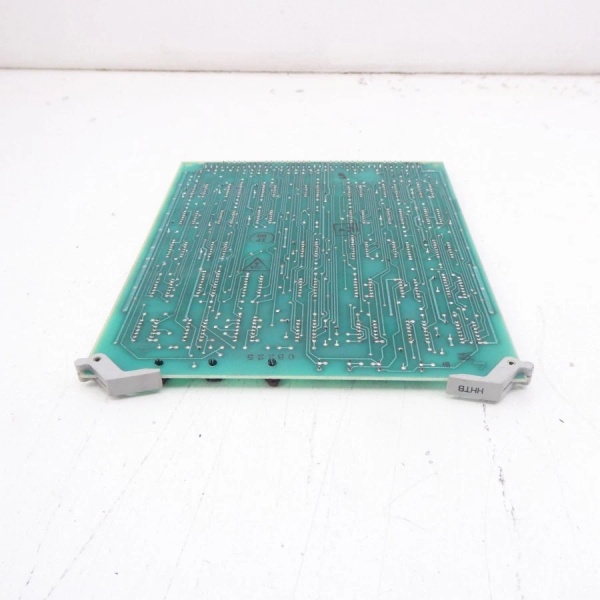

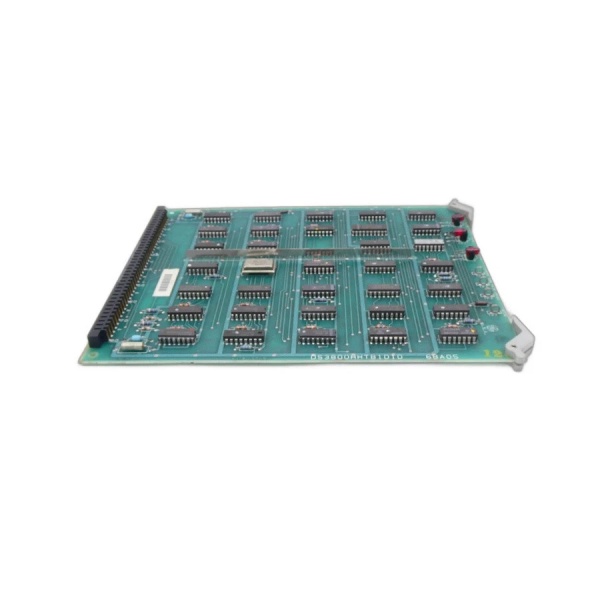

DS3800HHTB1D1D Product Overview

The DS3800HHTB1D1D is a high-density analog input board used inside GE Mark IV and Mark V Speedtronic turbine-control cubicles. It occupies one 6U card slot on the control backplane and converts low-level bipolar voltage signals (±1 V) from sensors such as servo valves, vibration probes, and pressure transducers into 15-bit digital codes for the microprocessor.

The DS3800HHTB1D1D is a high-density analog input board used inside GE Mark IV and Mark V Speedtronic turbine-control cubicles. It occupies one 6U card slot on the control backplane and converts low-level bipolar voltage signals (±1 V) from sensors such as servo valves, vibration probes, and pressure transducers into 15-bit digital codes for the microprocessor.

In the automation hierarchy the card sits at the “sensor interface” layer: it receives ±1 V differential signals on the field side, transformer-isolates each channel, and presents the digitized result to the VME bus. A 7.5 ms per-channel conversion rate keeps the speed-control loop responsive, while on-board BIT logic drives a front-panel LED to flag open inputs or over-range conditions.

The module belongs to the DS3800 “HHT” family of Mark IV personality boards—cards that share the same mechanical envelope and 96-pin edge connector but perform dedicated analog or timing functions. Using a common hardware platform allows plant stores to stock one spare chassis and populate it with the exact personality boards required for each turbine section.

DS3800HHTB1D1D

Technical Specifications

-

Model Number: DS3800HHTB1D1D

-

Manufacturer: General Electric

-

Product Type: Analog Input Module (differential voltage)

-

Input Channels: 8 differential, transformer-isolated

-

Input Range: -1 V … +1 V DC differential

-

Resolution: 15-bit (±0.003 % FSR)

-

Conversion Time: 7.5 ms per channel

-

Common-Mode Range: ±5 V (transformer isolated)

-

Input Impedance: >1 MΩ differential

-

Excitation Output: +24 VDC field supply (50 mA max) for two-wire transmitters

-

Data Interface: VME slave, A16 short I/O map, D16 transfers

-

Diagnostics: BIT LED (red = fault, green = ready)

-

Power: +5 V backplane @ 2 mA typical; optional external +24 V for field devices

-

Temperature: 0 … +70 °C operating, -40 … +85 °C storage

-

Form Factor: 6U single-slot VME64 slave

DS3800HHTB1D1D

Core Features & Customer Value

Transformer-isolated inputs – Each channel floats up to ±5 V common-mode, so ground-shift events (common when 4 kV breakers close) do not propagate into the microprocessor logic, improving measurement integrity and reducing nuisance faults.

Transformer-isolated inputs – Each channel floats up to ±5 V common-mode, so ground-shift events (common when 4 kV breakers close) do not propagate into the microprocessor logic, improving measurement integrity and reducing nuisance faults.

15-bit resolution at 7.5 ms – The combination gives ±0.003 % accuracy with enough speed for closed-loop servo or vibration monitoring; you can resolve micro-strain from a bonded-foil pressure cell or micro-g from an accelerometer without adding a separate signal conditioner.

24 V field excitation – An on-board 50 mA supply lets you power two-wire 4–20 mA transmitters or LVDTs directly, eliminating external DC supplies and their associated wiring and heat.

BIT LED & open-circuit flag – The red LED lights if any input is open or over-range, so during commissioning you can spot a broken sensor immediately without metering each pin at the terminal strip.

Drop-in spare – Shares the same DS3800 form factor as earlier HHT revisions; no mounting changes, no calibration downloads, and no external pots to adjust during swap-out.

Typical Applications

In combined-cycle plants the DS3800HHTB1D1D is installed in the “analog input” bay of every Mark IV or Mark V panel that governs gas turbines, boiler-feed pumps, or induced-draft fans. It measures ±1 V signals from servo-valve position sensors, vibration probes, and differential pressure transmitters and feeds the digitized result to the speed-control algorithm.

In combined-cycle plants the DS3800HHTB1D1D is installed in the “analog input” bay of every Mark IV or Mark V panel that governs gas turbines, boiler-feed pumps, or induced-draft fans. It measures ±1 V signals from servo-valve position sensors, vibration probes, and differential pressure transmitters and feeds the digitized result to the speed-control algorithm.

In pipeline compressor stations the same board reads ±1 V outputs from magnetic speed pickups and LVDT position sensors on inlet guide vanes; the 7.5 ms conversion time keeps the anti-surge loop stable during rapid transients.

Because the card is passive (no firmware) it is also accepted in nuclear standby turbine-generator sets, where “simple device” classification avoids additional software V&V.