Description

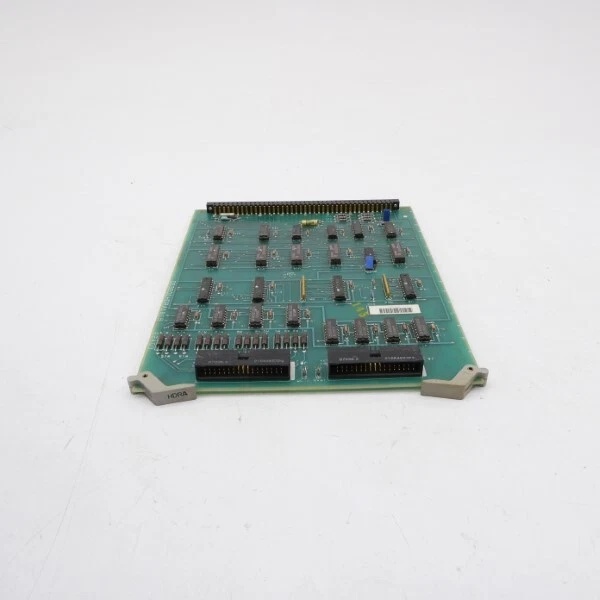

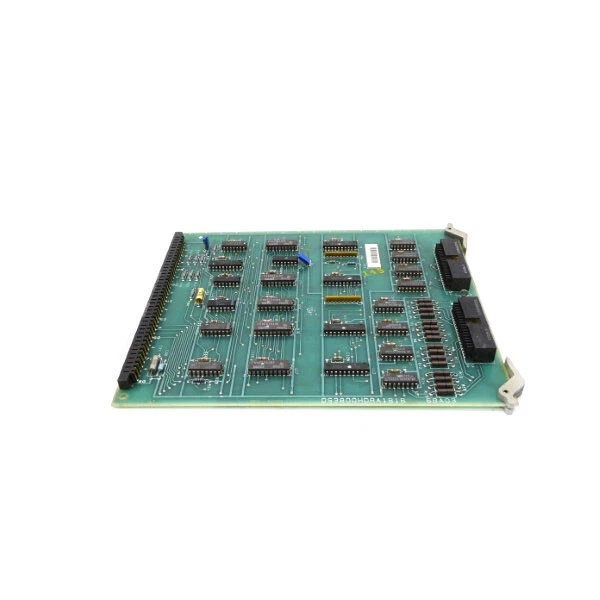

DS3800HDRA1B1B: Product Overview

The DS3800HDRA1B1B serves as a signal conditioning and communication interface within GE’s Speedtronic Mark IV turbine control architecture. Positioned within the control rack, this board functions as a critical bridge between field-terminated signals and the system’s central processing units, ensuring reliable data transmission across extended distances within industrial environments.

As a dedicated line driver and receiver, the board performs bidirectional signal conversion and amplification. On the transmission side, it boosts low-level logic signals to levels capable of driving long control cables without degradation, while the receiving circuitry conditions incoming signals to filter electrical noise and restore logic levels suitable for the Mark IV’s microprocessor-based control algorithms. The integration of transistor-transistor logic (TTL) devices provides robust interfacing between integrated circuits, ensuring compatibility with the digital logic standards employed throughout the platform.

This board belongs to the DS3800 series of the Mark IV platform, a control system renowned for its triple modular redundant (TMR) architecture designed for gas and steam turbine applications. While the line driver/receiver handles physical layer signal conditioning rather than voting logic, it operates within the same rigorous environmental and reliability standards as the broader Mark IV ecosystem. The platform’s distributed design allows for modular maintenance and diagnostic capabilities, ensuring that signal pathways remain intact even during individual board servicing.

DS3800HDRA1B1B

DS3800HDRA1B1B: Technical Specifications

-

Model Number: DS3800HDRA1B1B

-

Manufacturer: General Electric

-

Product Type: Line Driver/Receiver Board

-

Series: Mark IV

-

Signal Function: Bidirectional line driving and receiving with signal amplification

-

Front Interface: 2 x 40-pin connectors (front-accessible)

-

Backplane Connection: High-density modular connector for rack integration

-

Configuration Options: 2 jumpers for signal routing and termination settings

-

Logic Interface: Transistor-Transistor Logic (TTL) devices

-

Mounting Hardware: Integrated retention levers for secure rack mounting

-

Passive Components: Multiple capacitors for noise filtering and signal conditioning

-

Operating Environment: Industrial control cabinets (NEMA 1/12 compatible)

-

System Compatibility: GE Speedtronic Mark IV turbine control systems

Part 4: Core Features & Customer Value

Signal Integrity Over Extended Distances: The primary function of this line driver/receiver assembly is to overcome the signal degradation inherent in long cable runs within large turbine control enclosures. By amplifying outgoing signals to higher drive levels and conditioning incoming signals to reject induced electrical noise, the board ensures that command and feedback data remains uncorrupted between remote I/O terminals and the central processor. For engineers, this means reliable closed-loop control even when sensors and actuators are physically distant from the main control rack, eliminating the need for additional external signal boosters or repeaters.

Field-Configurable Architecture: The inclusion of two accessible jumpers allows technicians to modify signal routing and operational parameters without removing the board or reconfiguring software. This hardware-level configurability is essential when adapting the Mark IV system to different turbine models or retrofit applications where signal polarities or termination requirements vary. During commissioning or troubleshooting, these jumpers enable rapid isolation of signal paths, reducing the time required to verify wiring integrity or bypass faulty channels for maintenance.

Robust Physical Integration: The board features a high-density modular backplane connector that mates with the Mark IV rack, providing both signal paths and power distribution through a single insertion point. Retention levers ensure positive engagement and prevent vibration-induced backing out in industrial environments subject to turbine-induced mechanical resonance. This mechanical design supports hot-swappable maintenance procedures when properly sequenced with the redundant control channels, allowing technicians to replace the board without turbine shutdown. The front-mounted 40-pin connectors provide convenient access for portable logic analyzers or extension cables during system diagnostics, facilitating signal tracing without disturbing the backplane wiring.

DS3800HDRA1B1B

Part 5: Typical Applications

In heavy-duty gas turbine applications utilizing the Speedtronic Mark IV platform, the line driver/receiver is typically installed in the control rack to manage communication between the triple modular redundant processors and field-terminated I/O. In Frame 5, 6, and 7 gas turbines, this board drives status signals and analog setpoints over shielded multi-conductor cables extending to the turbine skid, where sensors monitor combustion dynamics, bearing temperatures, and shaft vibration. The board’s amplification capabilities ensure that logic-level signals maintain integrity across the 50 to 100-foot cable runs common in power plant installations, preventing signal attenuation that could lead to control instability or false protective trips.

Within combined-cycle power plants, the board facilitates communication between the gas turbine Mark IV controls and the steam turbine control systems or distributed control system (DCS) interfaces. When the Mark IV provides load demand signals or receives permissive interlocks from the plant DCS, the line driver/receiver conditions these discrete and pulse signals to withstand the electromagnetic interference generated by adjacent switchyard equipment or high-voltage buswork. This signal hardening is critical during grid disturbances when electrical noise peaks and control system availability is paramount.

The board also finds application in mechanical drive installations, such as gas turbines driving pipeline compressors or process pumps in petrochemical facilities. In these remote locations, the control rack may be housed in a separate building from the driven equipment, necessitating long cable runs through conduit. The receiving circuitry filters common-mode noise induced by variable frequency drives or ignition systems, ensuring that speed control signals and emergency shutdown commands are accurately transmitted without delay or corruption.