Description

DS3800DXRA1C1C: Product Overview

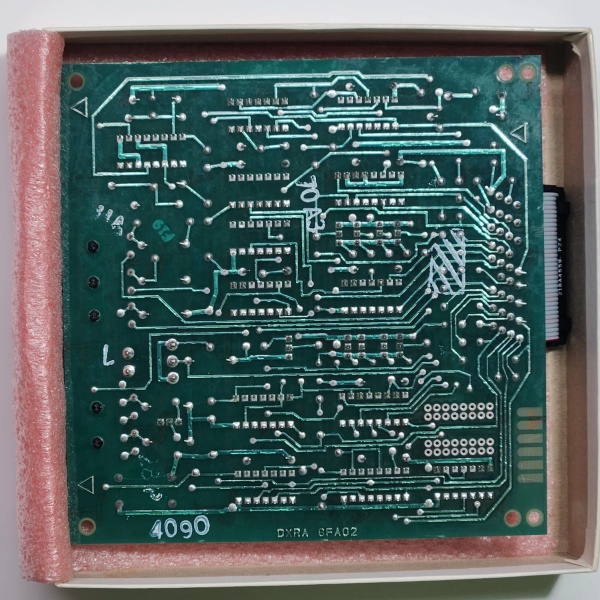

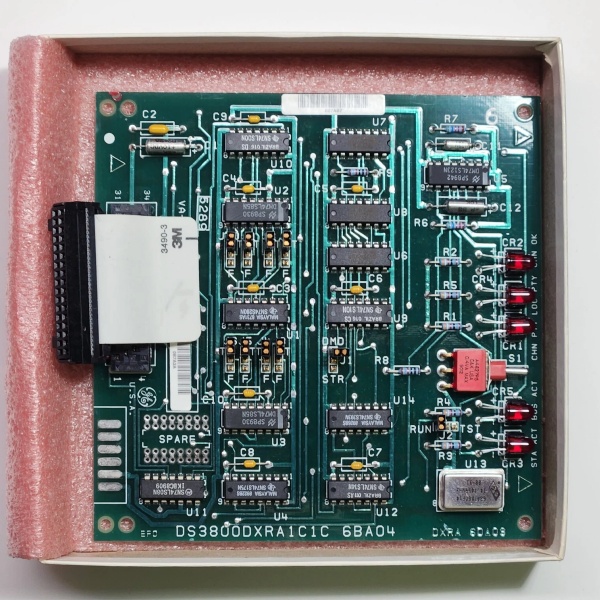

The DS3800DXRA1C1C functions as a critical signal reception interface within GE’s Speedtronic Mark IV turbine control architecture. Positioned in the data acquisition section of the system, this board receives incoming control signals from field devices, other control modules, or external systems and performs initial conditioning and buffering before transferring data to the system’s central processors. The “DXRA” designation identifies this as part of the Series Six receiver family, specifically optimized for high-reliability signal processing in turbine control applications.

The board incorporates a 20-pin connector that provides the primary interface for incoming signals, along with 10 configuration jumpers that allow field technicians to customize input characteristics for specific applications. The receiver circuits perform impedance matching, signal level translation, and noise filtering to ensure that control decisions are based on accurate, noise-free data. This signal conditioning is particularly critical in the electrically noisy environment of power generation facilities, where electromagnetic interference from large motors, switchgear, and transmission equipment can corrupt sensitive control signals.

As a member of the DS3800 series, the DXRA1C1C adheres to the standardized form factor and connector scheme established for the Mark IV platform. This standardization enables rapid field replacement and reduces spare parts inventory requirements for facilities maintaining legacy turbine control systems. The Series Six designation indicates this board supports the sixth generation of GE’s signal processing architecture, introduced to accommodate increased channel density and improved signal-to-noise performance compared to earlier implementations.

DS3800DXRA1C1C

DS3800DXRA1C1C: Technical Specifications

-

Model Number: DS3800DXRA1C1C

-

Manufacturer: General Electric

-

Product Type: Series Six Receiver Board

-

System Compatibility: Speedtronic Mark IV Turbine Control

-

Primary Function: Signal reception, conditioning, and processing

-

Connector Interface: 1 × 20-pin connector for signal input/output

-

Configuration: 10 × configuration jumpers for field customization

-

Signal Processing: Impedance matching, level translation, noise filtering

-

Mounting: Standard DS3800 series card cage with retention hardware

-

Operating Environment: Industrial control room, forced air cooling recommended

-

Weight: Approximately 0.5 lbs (0.23 kg)

Core Features & Customer Value

High-Reliability Signal Reception: The board’s receiver circuits are designed to maintain signal integrity even in the presence of electrical noise, ground potential differences, and long cable runs typical of industrial installations. For plant operators, this reliability ensures that control decisions are based on accurate process data rather than electrical artifacts, reducing the likelihood of false trips or control instability that could cause unplanned outages.

Field-Configurable Input Characteristics: The 10 configuration jumpers allow technicians to adapt the board’s input characteristics to match specific signal types and voltage levels without hardware modifications. This flexibility accommodates different sensor types, signal voltage ranges, and termination requirements that may vary between installations. During commissioning or retrofit projects, this configurability reduces the need for custom hardware or extensive rewiring.

Standardized Interface for Rapid Maintenance: The 20-pin connector provides a consistent interface that technicians can quickly identify and service using standard tools and procedures. The socketed design allows for connector replacement if pins become damaged, extending board service life. For facilities with multiple turbine units, this standardization reduces training requirements and spare parts inventory.

Series Six Architecture for Enhanced Performance: As part of GE’s Series Six receiver family, this board incorporates improved signal processing capabilities compared to earlier generations. The enhanced noise immunity and faster response times support the demanding requirements of modern turbine control algorithms while maintaining backward compatibility with existing Mark IV installations.

DS3800DXRA1C1C

Typical Applications

The DS3800DXRA1C1C is deployed in gas turbine control signal distribution systems, where it receives signals from speed sensors, temperature transmitters, and pressure transducers located on the turbine deck. In a typical Frame 7 or Frame 9 heavy-duty gas turbine, multiple DXRA boards operate in conjunction—each handling specific sensor groups that feed the system’s voting logic. The board’s signal conditioning ensures that measurements from remote field devices remain accurate despite long cable runs and electromagnetic interference.

In steam turbine supervisory instrumentation, this board processes signals from proximity probes monitoring shaft vibration, eccentricity detectors, and phase reference sensors. These measurements require high signal fidelity to detect mechanical faults measured in thousandths of an inch. The DXRA1C1C’s filtering and buffering ensure that subtle vibration signatures are preserved, enabling predictive maintenance strategies that avoid catastrophic failures.

The module also serves in turbine auxiliary system control, receiving signals from limit switches, pressure switches, and valve position indicators in lube oil, cooling water, and fuel gas systems. In these applications, the board’s configurable input characteristics accommodate both analog process variables and discrete status signals through the same hardware platform.