Description

DS3800DPZA1D1D: Product Overview

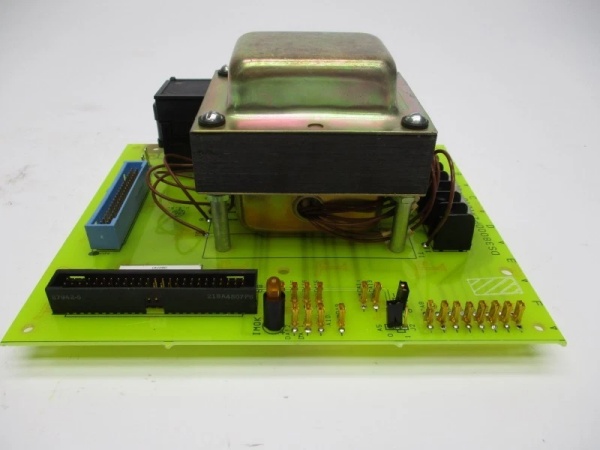

This board occupies a 6BA Euro-card slot in GE Mark IV turbine and EX2000 exciter control racks, serving as a zone-organized pulse and digital input interface. It aggregates up to 16 pulse or digital inputs into four independent zones, counts pulses within each zone, detects zone status changes, and reports condensed status words to the main CPU over the NDIA data bus. The “DPZA” designation indicates digital/pulse/zone auxiliary functionality, while the D1D revision includes enhanced zone isolation and independent scan rates per zone for mixed-speed applications.

This board occupies a 6BA Euro-card slot in GE Mark IV turbine and EX2000 exciter control racks, serving as a zone-organized pulse and digital input interface. It aggregates up to 16 pulse or digital inputs into four independent zones, counts pulses within each zone, detects zone status changes, and reports condensed status words to the main CPU over the NDIA data bus. The “DPZA” designation indicates digital/pulse/zone auxiliary functionality, while the D1D revision includes enhanced zone isolation and independent scan rates per zone for mixed-speed applications.

The epoxy-sealed construction makes this a line-replaceable module—internal faults require complete card swap rather than field repair. The module hot-swaps when the rack is powered down, and its low profile allows adjacent-slot population without additional cooling. As part of the DS3800 family, it benefits from the Mark IV platform’s deterministic 2 ms control interval and extensive installed base in power generation applications.

DS3800DPZA1D1D: Technical Specifications

-

Model Number: DS3800DPZA1D1D

-

Manufacturer: General Electric (GE Fanuc)

-

Product Type: Digital Pulse Zone Auxiliary / Multi-Zone Counter Board

-

Series: DS3800, Mark IV Speedtronic

-

Form Factor: 6BA Euro-card (≈ 233 × 160 mm)

-

Back-Plane Connector: Dual 40-pin header (J1/J2)

-

Input Organization: 4 zones × 4 inputs (16 total)

-

Input Type: Differential TTL pulse or 24 Vdc digital (zone-selectable)

-

Count Rate: 1 MHz per zone (4 MHz aggregate)

-

Zone Isolation: 500 V between zones (D1D enhancement)

-

Scan Rate: 2 ms default; 0.5–10 ms selectable per zone (D1D feature)

-

Isolation: 1500 Vdc field-to-logic; opto-coupled inputs

-

Power Demand: +5 V @ 0.8 A, +15 V @ 0.3 A, +24 V @ 0.2 A from rack 2PL bus

-

Operating Temperature: 0 – 60 °C

-

Weight: ≈ 0.26 kg

-

Construction: Epoxy-sealed copper traces—non-repairable

DS3800DPZA1D1D

Core Features & Customer Value

Zone-Based Organization: The four-zone architecture allows grouping related inputs (e.g., one zone per bearing, one per blade row) with independent scan rates. For vibration analysts, this enables high-speed sampling on critical zones while conserving bus bandwidth on slower channels—optimizing the 2 ms CPU scan for maximum information density.

Independent Zone Timing: The D1D revision adds per-zone scan rate selection (0.5–10 ms). For control engineers, this means blade-pass monitoring at 0.5 ms resolution in Zone 1 while lube pressure switches update at 10 ms in Zone 4, all on one card without software overhead.

Zone Isolation: The 500 V inter-zone isolation prevents fault propagation between zones. For protection engineers, a shorted pulse pickup in the turbine bearing zone will not corrupt data from the generator bearing zone, maintaining partial monitoring capability during degraded conditions.

Epoxy-Sealed Construction: All internal copper is encapsulated in high-temperature epoxy. In coastal or industrial environments with conductive dust and high humidity, this prevents trace-to-trace shorting that would cause zone crosstalk or false counts after ten-plus years. The trade-off is non-repairability—internal faults require whole-card exchange—but this is offset by reduced troubleshooting time and single-spare stocking rather than maintaining a repair bench.

Typical Applications

In combined-cycle power plants, this board installs in the Mark IV turbine control core where it organizes vibration monitoring by zone: Zone 1 for compressor bearings, Zone 2 for turbine bearings, Zone 3 for generator bearings, and Zone 4 for blade-pass timing. The independent scan rates match sensor criticality—0.5 ms for blade pass, 2 ms for turbine bearings, 10 ms for generator bearings.

On utility-scale EX2000 static exciters, the same card zones the diode-fail monitoring by rectifier bridge quadrant, with 1 MHz counting for fast failure detection and 10 ms digital inputs for cooling fan status. Zone isolation ensures a ground fault in one bridge does not mask failures in others.

Mechanical-drive gas compressors frequently use this part number with Zone 1 for high-speed crank position, Zone 2 for cylinder pressure switches, Zone 3 for valve position pulses, and Zone 4 for auxiliary equipment status. The zone organization simplifies software by pre-grouping related inputs into coherent status words.