Description

DS3800DMPC1F1E Product Overview

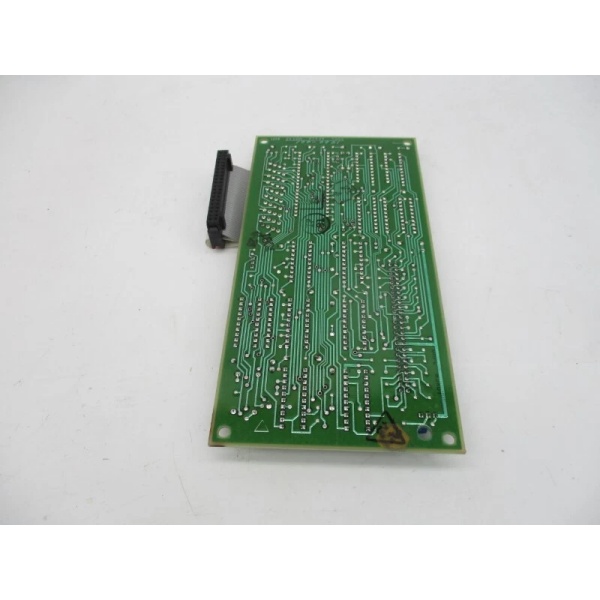

The DS3800DMPC1F1E is a DSP-based mixed-signal I/O and communication card used inside GE Mark IV and Mark VIe Speedtronic turbine-control cubicles. Occupying a 6U VME-style slot, it acts as the real-time interface between the turbine-control microprocessor and field devices such as servo valves, temperature transmitters, and auxiliary motor contactors.

The DS3800DMPC1F1E is a DSP-based mixed-signal I/O and communication card used inside GE Mark IV and Mark VIe Speedtronic turbine-control cubicles. Occupying a 6U VME-style slot, it acts as the real-time interface between the turbine-control microprocessor and field devices such as servo valves, temperature transmitters, and auxiliary motor contactors.

In the automation hierarchy the card sits at the “fast I/O & fieldbus” layer: it digitizes 16-bit analog sensor signals, drives 4-20 mA or ±10 V actuators, handles 24 V discrete logic, and exchanges data over ProfiBus DP, EtherCAT, or Modbus TCP/RTU without requiring an external gateway. An on-board DSP performs local loop control, filtering, and alarm algorithms, off-loading the main CPU and reducing scan-time jitter.

The module belongs to the DS3800 “DMPC” family of Mark IV personality boards—cards that share the same 96-pin edge connector and mechanical envelope but implement dedicated control or communication tasks. This common hardware platform allows plant stores to stock one spare chassis and populate it with the exact personality boards required for each turbine section

GE DS3800DMPC1F1E

.

Technical Specifications

-

Model Number: DS3800DMPC1F1E

-

Manufacturer: General Electric

-

Product Type: DSP-Based Analog & Digital I/O Communication Module

-

Processor: High-performance DSP, real-time signal processing optimized

-

Analog Input: 8 channels, 16-bit, ±10 V or 4-20 mA, 250 V channel isolation

-

Analog Output: 4 channels, 16-bit, 0-10 V or 4-20 mA, short-circuit protected

-

Digital Input: 16 channels, 24 VDC, photo-isolated, logic-level selectable

-

Digital Output: 16 channels, relay output, 24 VDC load, 500 mA per point

-

Fieldbus: ProfiBus DP, EtherCAT, Modbus TCP/RTU (software-selectable)

-

Ethernet: 10/100 Mbps RJ45, real-time data stream supported

-

Power Supply: 24 VDC ±10 %, 3 A typical (field & logic)

-

Isolation: 250 V channel-to-bus, meets EN 61000-6-2

-

Protection: Over-voltage, over-current, short-circuit detection with auto-shutdown

-

Temperature: -20 … +70 °C operating, -40 … +85 °C storage

-

Form Factor: 6U single-slot VME64 slave, 6BA08 revision marking

Core Features & Customer Value

On-board DSP engine – Local PID, filtering, and alarm algorithms run in <1 ms, off-loading the main CPU and keeping turbine-control loops deterministic even during heavy I/O traffic.

On-board DSP engine – Local PID, filtering, and alarm algorithms run in <1 ms, off-loading the main CPU and keeping turbine-control loops deterministic even during heavy I/O traffic.

Multi-protocol fieldbus – ProfiBus DP, EtherCAT, and Modbus are selectable in software, so the same card can be dropped into a Mark IV ProfiBus segment or a Mark VIe EtherCAT ring without hardware changes, saving spares and engineering hours.

16-bit analog chain – ±10 V or 4-20 mA I/O with 250 V isolation means you can wire servo valves and pressure transmitters directly—no external signal conditioners—while maintaining 0.003 % resolution for tight speed or temperature control.

Relay + photo-isolated digital I/O – 32 digital points handle both wet-contact status (inputs) and coil-driving outputs (500 mA relays), eliminating interposing relays and saving panel space.

Industrial temperature & protection – -20 … +70 °C rating plus auto-shutdown on over-current means the card survives cooling-fan failures and shorted field cables without damaging the backplane.

GE DS3800DMPC1F1E

Typical Applications

In combined-cycle plants the DS3800DMPC1F1E is installed in the “I/O & communication” bay of every Mark IV or Mark VIe panel that governs gas turbines. It digitizes ±1 V servo-valve feedback, drives 4-20 mA inlet-guide-vane positioners, and exchanges real-time data with the plant DCS over EtherCAT— all on one card.

In combined-cycle plants the DS3800DMPC1F1E is installed in the “I/O & communication” bay of every Mark IV or Mark VIe panel that governs gas turbines. It digitizes ±1 V servo-valve feedback, drives 4-20 mA inlet-guide-vane positioners, and exchanges real-time data with the plant DCS over EtherCAT— all on one card.

In pipeline compressor stations the same module reads 4-20 mA suction/discharge pressure transmitters, outputs ±10 V to the anti-surge valve servo, and publishes compressor maps over ProfiBus to the station PLC.

Because the DSP runs locally, the card is also accepted in safety-related nuclear standby turbine-generator sets, where deterministic response (<10 ms) is required for overspeed protection loops.