Description

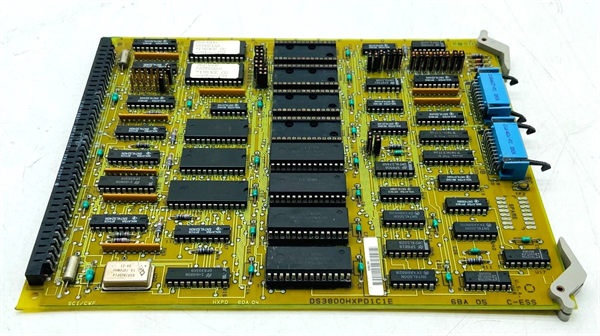

DS3800DI0H1D1E: Product Overview

The board functions as a discrete signal interface and isolation module within the Speedtronic Mark IV turbine control architecture. Positioned within the control rack assembly, this unit manages the bidirectional flow of digital status and command signals between field devices and the central microprocessor complex. In the Mark IV’s triple modular redundant (TMR) system, this board operates within each independent control channel, ensuring that discrete status inputs are reliably captured and that control outputs are safely transmitted to field actuators.

As a digital I/O interface, the unit handles the electrical translation and isolation required for industrial discrete signals. It receives status inputs from field contacts such as limit switches, pressure switches, and relay auxiliary contacts, converting these mechanical or electrical states into logic levels compatible with the Mark IV microprocessors. Simultaneously, it drives discrete outputs to control relay coils, solenoid valves, and indicator lamps with appropriate voltage and current levels. The board’s optocoupler-based isolation circuitry prevents ground loop currents and protects sensitive control electronics from high-voltage transients that may appear on field wiring.

The board supports standard industrial voltage levels commonly found in power generation environments, including 24VDC and 125VDC station battery circuits. Input circuits feature debouncing and filtering to prevent false triggering from contact bounce or electrical noise, while output circuits provide short-circuit protection and inductive kickback suppression for driving relay coils. The high-density modular backplane connector ensures reliable communication with the central processors while maintaining the physical robustness required for continuous operation in turbine control enclosures.

This board belongs to the DS3800 series of the Mark IV platform, deployed across heavy-duty gas turbines (Frame 3, 5, 6, 7, 9) and LM aeroderivative units. The platform’s distributed architecture allows discrete I/O functions to execute at the rack level while maintaining deterministic synchronization with the control algorithms, ensuring that protective actions and sequencing logic operate with the millisecond-level timing required for turbine safety systems.

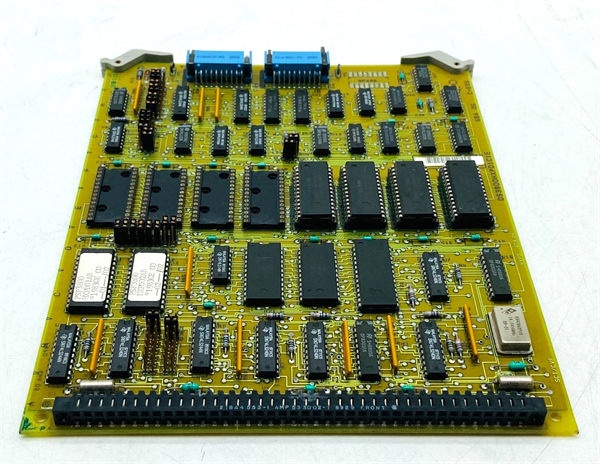

DS3800HXPD1C1E

DS3800DI0H1D1E: Technical Specifications

-

Model Number: DS3800DI0H1D1E

-

Manufacturer: General Electric

-

Product Type: Digital Input/Output Interface Board

-

Series: GE Speedtronic Mark IV

-

Architecture: Triple Modular Redundant (TMR) compatible

-

Form Factor: 6BA02 standard Mark IV board format

-

Input Types: Discrete dry contacts, 24VDC/125VDC wet inputs

-

Output Types: Relay driver outputs, 24VDC/125VDC discrete outputs

-

Isolation: Optocoupler-based galvanic isolation between field and logic sides

-

Channels: Multiple discrete input and output channels (typically 8-16 channels per board)

-

Input Conditioning: Debouncing circuits and noise filtering

-

Output Protection: Inductive kickback suppression (freewheeling diodes), short-circuit protection

-

Backplane Interface: High-density modular connector (AMD 218A4553-1 compatible)

-

Operating Temperature: -40°C to +70°C (industrial grade)

-

Storage Temperature: -40°C to +85°C

-

Humidity: 5% to 95% non-condensing

-

Vibration/Shock: 5 g vibration / 50 g shock (per Mark IV specifications)

-

Mounting: Standard Mark IV rack slot with integrated retention levers

Part 4: Core Features & Customer Value

Robust Electrical Isolation for System Protection:

The primary function of this board is to provide galvanic isolation between field wiring and sensitive control electronics using optocoupler technology. This isolation prevents ground loop currents—common in industrial power plants where multiple ground reference points exist—from corrupting logic levels or damaging microprocessor circuits. In turbine applications where high-voltage switching and generator excitation systems create substantial electrical noise, this isolation ensures that discrete status signals remain reliable and that control outputs do not inadvertently conduct fault currents into the central control system.

The primary function of this board is to provide galvanic isolation between field wiring and sensitive control electronics using optocoupler technology. This isolation prevents ground loop currents—common in industrial power plants where multiple ground reference points exist—from corrupting logic levels or damaging microprocessor circuits. In turbine applications where high-voltage switching and generator excitation systems create substantial electrical noise, this isolation ensures that discrete status signals remain reliable and that control outputs do not inadvertently conduct fault currents into the central control system.

Comprehensive Input Conditioning:

Discrete input channels incorporate hardware debouncing and noise filtering that prevent false triggering from mechanical contact bounce or transient electrical interference. When monitoring limit switches on vibrating turbine components or pressure switches in electrically noisy environments, these filtering circuits ensure that only genuine state changes are registered by the control system. For operators, this eliminates nuisance alarms and spurious trips that could otherwise interrupt turbine operation; for maintenance personnel, it reduces troubleshooting time spent chasing intermittent electrical ghosts.

Discrete input channels incorporate hardware debouncing and noise filtering that prevent false triggering from mechanical contact bounce or transient electrical interference. When monitoring limit switches on vibrating turbine components or pressure switches in electrically noisy environments, these filtering circuits ensure that only genuine state changes are registered by the control system. For operators, this eliminates nuisance alarms and spurious trips that could otherwise interrupt turbine operation; for maintenance personnel, it reduces troubleshooting time spent chasing intermittent electrical ghosts.

High-Voltage Output Drive Capability:

Output channels are designed to drive standard industrial loads including relay coils, contactor solenoids, and indicator lamps operating at 24VDC or 125VDC. Integrated freewheeling diodes and kickback suppression protect the output transistors from the inductive voltage spikes generated when de-energizing large relay coils common in turbine auxiliary control schemes. This protection extends the operational life of the board and reduces the frequency of replacements in high-cycling applications such as sequential control of auxiliary motors during turbine startup sequences.

Output channels are designed to drive standard industrial loads including relay coils, contactor solenoids, and indicator lamps operating at 24VDC or 125VDC. Integrated freewheeling diodes and kickback suppression protect the output transistors from the inductive voltage spikes generated when de-energizing large relay coils common in turbine auxiliary control schemes. This protection extends the operational life of the board and reduces the frequency of replacements in high-cycling applications such as sequential control of auxiliary motors during turbine startup sequences.

Hot-Swappable Redundancy for Availability:

The board supports replacement within the Mark IV TMR architecture, allowing technicians to restore discrete I/O functionality without turbine shutdown. Standardized retention hardware ensures positive mechanical engagement despite the vibration environment typical of turbine enclosures. This maintainability is essential for discrete I/O channels controlling critical safety functions or permissive interlocks, as it allows failed channels to be restored quickly using available spare inventory, maintaining the redundancy necessary for safe continued operation.

The board supports replacement within the Mark IV TMR architecture, allowing technicians to restore discrete I/O functionality without turbine shutdown. Standardized retention hardware ensures positive mechanical engagement despite the vibration environment typical of turbine enclosures. This maintainability is essential for discrete I/O channels controlling critical safety functions or permissive interlocks, as it allows failed channels to be restored quickly using available spare inventory, maintaining the redundancy necessary for safe continued operation.

Flexible Voltage Compatibility:

The board accommodates the mixed voltage levels commonly encountered in industrial turbine installations, interfacing with 24VDC instrumentation circuits and 125VDC station battery systems within the same hardware platform. This flexibility eliminates the need for separate I/O boards for different voltage systems, reducing spare parts inventory and simplifying system design for facilities with diverse auxiliary equipment.

The board accommodates the mixed voltage levels commonly encountered in industrial turbine installations, interfacing with 24VDC instrumentation circuits and 125VDC station battery systems within the same hardware platform. This flexibility eliminates the need for separate I/O boards for different voltage systems, reducing spare parts inventory and simplifying system design for facilities with diverse auxiliary equipment.

DS3800HXPD1C1E

Part 5: Typical Applications

Gas Turbine Auxiliary Sequencing and Interlocks:

The board is deployed in GE Frame 5, 6, and 7 gas turbines to manage the discrete status inputs and command outputs required for auxiliary system sequencing. In these applications, it receives status signals from lube oil pressure switches, cooling fan proof-of-flow contacts, and fuel valve limit switches. It outputs control commands to relay coils that energize auxiliary pumps, open fuel valves, and actuate ventilation dampers during the turbine startup sequence. The deterministic response ensures that permissive interlocks—such as requiring lube oil pressure confirmation before allowing turbine roll-up—are evaluated within milliseconds, preventing mechanical damage from improper sequencing.

The board is deployed in GE Frame 5, 6, and 7 gas turbines to manage the discrete status inputs and command outputs required for auxiliary system sequencing. In these applications, it receives status signals from lube oil pressure switches, cooling fan proof-of-flow contacts, and fuel valve limit switches. It outputs control commands to relay coils that energize auxiliary pumps, open fuel valves, and actuate ventilation dampers during the turbine startup sequence. The deterministic response ensures that permissive interlocks—such as requiring lube oil pressure confirmation before allowing turbine roll-up—are evaluated within milliseconds, preventing mechanical damage from improper sequencing.

Steam Turbine Protection System Interface:

In steam turbine applications within paper mills and petrochemical facilities, this board provides the discrete I/O interface for protective trip systems. It monitors the status of emergency stop buttons, overspeed governor trip contacts, and bearing temperature switch contacts, providing the isolated inputs necessary for safety instrumented functions. Simultaneously, it drives output relays that trip main steam valves and excitation field breakers when protective logic detects unsafe conditions. The robust isolation ensures that faults in the high-voltage 125VDC trip circuits cannot propagate into the safety logic solvers, maintaining the integrity of protective functions.

In steam turbine applications within paper mills and petrochemical facilities, this board provides the discrete I/O interface for protective trip systems. It monitors the status of emergency stop buttons, overspeed governor trip contacts, and bearing temperature switch contacts, providing the isolated inputs necessary for safety instrumented functions. Simultaneously, it drives output relays that trip main steam valves and excitation field breakers when protective logic detects unsafe conditions. The robust isolation ensures that faults in the high-voltage 125VDC trip circuits cannot propagate into the safety logic solvers, maintaining the integrity of protective functions.

Aeroderivative Package Control and Status:

For LM6000 and LM2500 units, the board manages the concentrated discrete I/O requirements of compact aeroderivative packages. It interfaces with package-mounted limit switches indicating inlet guide vane position, fuel nozzle valve status, and compartment door interlocks. The compact 6BA02 form factor allows efficient use of limited control cabinet space while providing the channel density necessary for comprehensive package monitoring. The board’s filtering capabilities accommodate the higher vibration environments typical of these high-speed machines.

For LM6000 and LM2500 units, the board manages the concentrated discrete I/O requirements of compact aeroderivative packages. It interfaces with package-mounted limit switches indicating inlet guide vane position, fuel nozzle valve status, and compartment door interlocks. The compact 6BA02 form factor allows efficient use of limited control cabinet space while providing the channel density necessary for comprehensive package monitoring. The board’s filtering capabilities accommodate the higher vibration environments typical of these high-speed machines.

Generator Excitation and Switchyard Interface:

The board monitors discrete status from generator field breakers, excitation system contactors, and switchyard isolators. It provides the necessary 125VDC compatibility to interface with standard power plant station battery circuits used for breaker control and status indication. By isolating these high-voltage DC circuits from the low-voltage control logic, the board ensures that switchyard transients and ground faults do not disrupt turbine control functions or damage sensitive microprocessor modules.

The board monitors discrete status from generator field breakers, excitation system contactors, and switchyard isolators. It provides the necessary 125VDC compatibility to interface with standard power plant station battery circuits used for breaker control and status indication. By isolating these high-voltage DC circuits from the low-voltage control logic, the board ensures that switchyard transients and ground faults do not disrupt turbine control functions or damage sensitive microprocessor modules.

Balance of Plant Equipment Control:

In combined cycle power plants, the board extends discrete control capabilities to heat recovery steam generators, cooling tower systems, and fuel forwarding skids. It sequences auxiliary equipment such as condensate pumps, cooling water circulation pumps, and fuel forwarding pumps through discrete start/stop commands, while monitoring status feedback from motor control centers and flow switches. The isolation features protect the main turbine control system from electrical disturbances generated by large motor starters and variable frequency drives in these auxiliary systems.

In combined cycle power plants, the board extends discrete control capabilities to heat recovery steam generators, cooling tower systems, and fuel forwarding skids. It sequences auxiliary equipment such as condensate pumps, cooling water circulation pumps, and fuel forwarding pumps through discrete start/stop commands, while monitoring status feedback from motor control centers and flow switches. The isolation features protect the main turbine control system from electrical disturbances generated by large motor starters and variable frequency drives in these auxiliary systems.