Description

DS3800DFPN1A1A Product Overview

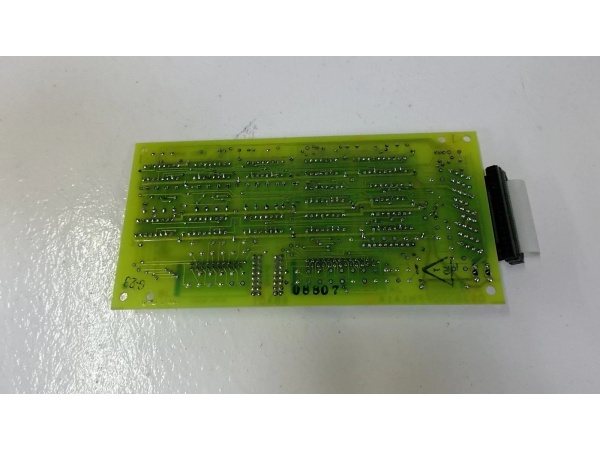

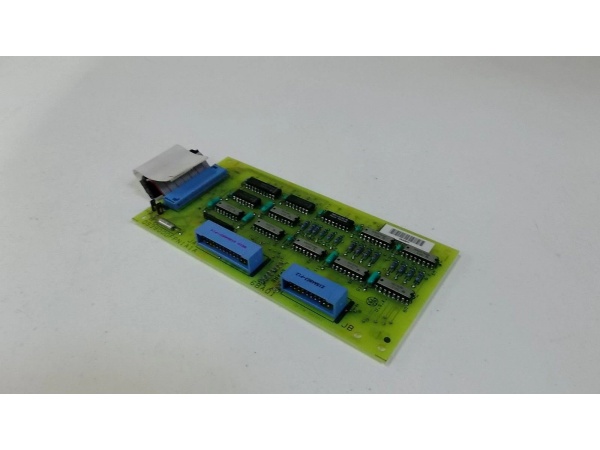

The DS3800DFPN1A1A is an auxiliary field-control PC board that resides in GE Mark IV turbine and EX2000 exciter control racks. It occupies a 6BA Euro-card slot and acts as a distributed logic node: it hosts local control algorithms (lube-oil sequencing, cooling-fan logic), buffers field I/O, and isolates the 5 V CPU from the 24 Vdc/480 V field circuits. All copper traces are fully encapsulated in high-temperature epoxy, making the unit non-repairable—any internal fault requires a complete card swap rather than component-level rework. The board is factory-sealed and Made in USA, ensuring long-term traceability for critical-infrastructure sites that must comply with domestic-content or Buy-American provisions.

The DS3800DFPN1A1A is an auxiliary field-control PC board that resides in GE Mark IV turbine and EX2000 exciter control racks. It occupies a 6BA Euro-card slot and acts as a distributed logic node: it hosts local control algorithms (lube-oil sequencing, cooling-fan logic), buffers field I/O, and isolates the 5 V CPU from the 24 Vdc/480 V field circuits. All copper traces are fully encapsulated in high-temperature epoxy, making the unit non-repairable—any internal fault requires a complete card swap rather than component-level rework. The board is factory-sealed and Made in USA, ensuring long-term traceability for critical-infrastructure sites that must comply with domestic-content or Buy-American provisions.

GE DS3800DFPN1A1A

DS3800DFPN1A1A Technical Specifications

-

Model Number: DS3800DFPN1A1A

-

Manufacturer: General Electric (GE Fanuc)

-

Product Type: Field Control / Auxiliary PC Board

-

Series: DS3800, Mark IV Speedtronic

-

Form Factor: 6BA Euro-card (≈ 233 × 160 mm)

-

Back-Plane Connector: Dual 40-pin header (J1/J2)

-

Power Supply: 24 Vdc nominal (18–36 Vdc range typical)

-

Isolation: 1500 Vdc field-to-logic; opto-coupled data lines

-

Operating Temperature: 0 – 60 °C

-

Construction: Epoxy-sealed copper traces—non-repairable

-

Country of Origin: Made in USA

Core Features & Customer Value

Distributed Field Logic: The on-board microprocessor executes fast auxiliary loops (lube pumps, cooling fans) locally, off-loading the main 5 V CPU. This guarantees deterministic response times even when the central processor is busy with sequencing or communications, reducing the risk of auxiliary-trip delays during start-up.

Epoxy-Sealed Construction: All internal copper is encapsulated in high-temperature epoxy. In coastal or industrial sites with conductive dust and high humidity the seal prevents trace-to-trace shorting that would otherwise cause random “AUX CONTROL FAIL” alarms after ten-plus years of service. The trade-off is non-repairability—any internal fault requires a whole-card exchange—but this is offset by reduced troubleshooting time and the fact that plants stock one spare instead of maintaining a repair bench.

Made-in-USA Supply Chain: The board is factory-sealed and manufactured in the United States, ensuring traceability and long-term spares availability for critical-infrastructure sites that must comply with domestic-content or Buy-American provisions.

GE DS3800DFPN1A1A

Typical Applications

In combined-cycle power plants the board is installed in the Mark IV turbine control core where it hosts the 24 Vdc auxiliary sequencing logic for the lube-oil pump, cooling-fan contactors, and hydraulic trip solenoid. The on-board opto-isolators keep 480 V switching transients from walking into the 5 V CPU data bus.

On utility-scale EX2000 static exciters the same card is used to manage the brushless-exciter cooling-fan starter and the field-discharge contactor. Because the inputs are group-isolated, a shorted fan motor will not drag down the entire digital I/O rack.

Frequently the same part number is used on mechanical-drive gas compressors to sequence the 24 Vdc inlet-guide-vane hydraulic pump. Its ability to mix 24 V logic with isolation on one card makes it a universal “auxiliary CPU” for any Mark IV loop that needs deterministic, battery-free operation.