Description

DS200TCQBG1BCA Product Overview

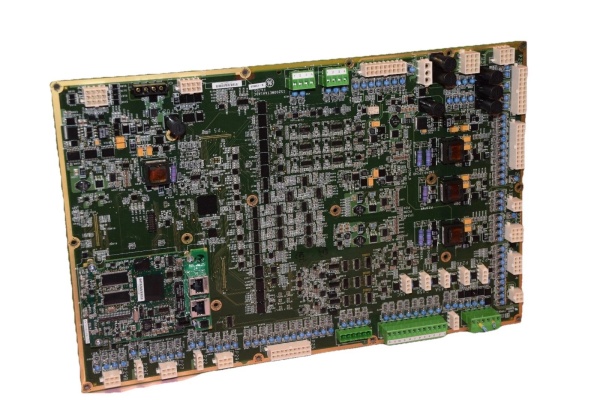

The DS200TCQBG1BCA is an RST Extended Analog I/O printed-circuit board used inside GE Mark V Speedtronic turbine and compressor control cubicles. It occupies a standard card slot on the Mark V control backplane and acts as the low-level interface between the controller’s analog-to-digital converters and field 4–20 mA or 0–200 mA loops.

The DS200TCQBG1BCA is an RST Extended Analog I/O printed-circuit board used inside GE Mark V Speedtronic turbine and compressor control cubicles. It occupies a standard card slot on the Mark V control backplane and acts as the low-level interface between the controller’s analog-to-digital converters and field 4–20 mA or 0–200 mA loops.

In the automation hierarchy the board sits at the “analog termination” layer: it receives differential current signals from transmitters, burdens them through precision resistors, and presents a low-noise voltage to the on-board A/D subsystem. Conversely, it sources up to 200 mA on two independent output loops to drive positioners or magnetic amplifiers. All ranges are set with jumper banks BJ1-BJ17—no software download required—so site-specific curves can be changed with the rack powered down.

The card is part of the DS200 “RST” family of Mark V personality boards—modules that share the same 96-pin edge connector and mechanical envelope but implement dedicated analog or timing functions. Using a common hardware platform allows plant stores to stock one spare chassis and populate it with the exact personality boards required for each turbine section.

IS200WETAH1ADC

Technical Specifications

-

Model Number: DS200TCQBG1BCA

-

Manufacturer: General Electric

-

Product Type: RST Extended Analog I/O Board

-

Input Channels: 15 differential, milliampere (4–20 mA default)

-

Output Channels: 2 milliampere, jumper-selectable 20 mA or 200 mA full-scale

-

Burden Resistor: 250 Ω ±0.1 % (inputs)

-

Output Compliance: 20 V @ 200 mA (max)

-

Jumper Banks: BJ1-BJ17 (BJ1-BJ15 = input range / DCOM; BJ16-BJ17 = output range select)

-

Isolation: Basic insulation; field-side common tied to DCOM jumper

-

Memory: On-board EPROM for calibration constants

-

Status Indication: Front-panel green “OK” LED

-

Connectors: 96-pin DIN edge finger (backplane), no external field terminals

-

Mounting: Standard Mark V card rails, captive screws

-

Weight: ≈ 0.25 kg (0.55 lb)

-

Operating Temperature: 0 … +55 °C (Mark V cabinet ambient)

-

Storage Temperature: –40 … +85 °C

-

Vibration/Shock: 5 g / 50 g (per Mark V cabinet spec)

Core Features & Customer Value

15 + 2 channel density – One card replaces separate input and output analog boards, freeing Mark V slots and reducing spare-part count while keeping the same 4–20 mA / 0–200 mA capability.

15 + 2 channel density – One card replaces separate input and output analog boards, freeing Mark V slots and reducing spare-part count while keeping the same 4–20 mA / 0–200 mA capability.

Jumper-selectable ranges – BJ1-BJ17 jumpers set input/output ranges without software; site-specific curves can be changed during an outage without a laptop or download cable.

250 Ω precision burden – Factory-trimmed to ±0.1 %, so loop accuracy is maintained without user calibration and external shunts are eliminated.

Front-panel OK LED – Local visual confirmation that all rails are within tolerance; during commissioning you can spot a failing input immediately without metering each pin at the terminal strip.

Drop-in spare – Shares the DS200 RST form factor with earlier TCQ* revisions; no mounting changes, no parameter downloads, and no calibration required during swap-out.

IS200WETAH1ADC

Typical Applications

In combined-cycle plants the DS200TCQBG1BCA is installed in the “analog I/O” section of Mark V panels that govern gas-turbine fuel flow, inlet-guide-vane position, and cooling-water temperature. The 15 input channels accept 4–20 mA from pressure and temperature transmitters, while the two 200 mA outputs drive magnetic amplifiers or servo-valve coils.

In combined-cycle plants the DS200TCQBG1BCA is installed in the “analog I/O” section of Mark V panels that govern gas-turbine fuel flow, inlet-guide-vane position, and cooling-water temperature. The 15 input channels accept 4–20 mA from pressure and temperature transmitters, while the two 200 mA outputs drive magnetic amplifiers or servo-valve coils.

In pipeline compressor stations the same board reads 4–20 mA from suction/discharge pressure transmitters and sources 0–200 mA to the anti-surge valve positioner, using the jumper-selectable ranges to match different valve brands without hardware changes.

Because the card is certified for marine environments, it is also used on off-shore platforms for well-head pressure and subsea valve-position feedback without needing additional isolation barriers.