Description

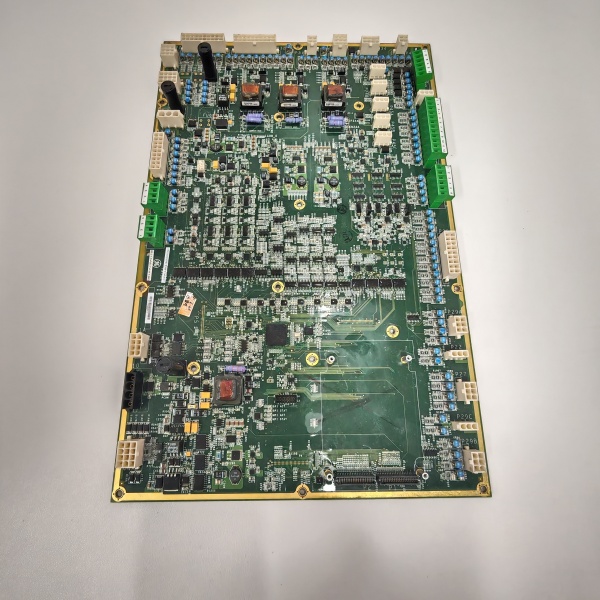

DS200STBAG1ADC Product Overview

The DS200STBAG1ADC is an RST (Resistive Sensor Terminal) mixed-I/O termination board used inside GE Mark V Speedtronic turbine and compressor control cubicles. It occupies a double-slot VME position and provides 180 termination points for field sensors—primarily RTDs, thermocouples, and 4-20 mA transmitters—plus a limited number of discrete inputs/outputs.

The DS200STBAG1ADC is an RST (Resistive Sensor Terminal) mixed-I/O termination board used inside GE Mark V Speedtronic turbine and compressor control cubicles. It occupies a double-slot VME position and provides 180 termination points for field sensors—primarily RTDs, thermocouples, and 4-20 mA transmitters—plus a limited number of discrete inputs/outputs.

In the control hierarchy the board sits at the “field-signal interface” layer: it burdens current loops, excites 3-/4-wire RTDs, cold-junction-compensates thermocouples, and converts raw resistance or current into conditioned ±10 V or 0–10 V signals that the Mark V CPU digitizes. On-board trim-pots and jumper banks allow site-specific scaling without software downloads.

Because the card is passive (no processor) and carries conformal coating, it is accepted in safety-related turbine-compressor drives where “simple device” classification avoids additional software V&V.

GE IS200WETAH1AEC

Technical Specifications

-

Model Number: DS200STBAG1ADC

-

Manufacturer: General Electric

-

Product Type: RST Mixed-I/O Terminal Board

-

Termination Points: 180 screw-clamp terminals (RTD, mA, discrete)

-

Sensor Types: RTD (Pt100, Cu10, etc.), thermocouple (J, K, T, E), 4–20 mA, dry-contact discrete I/O

-

Signal Conditioning: On-board bridge completion, cold-junction compensation, 250 Ω burden resistors

-

Output to CPU: Conditioned ±10 V or 0–10 V per channel

-

Isolation: 1500 V channel-to-ground basic insulation

-

Logic Supply: 24 VDC derived from Mark V backplane

-

Temperature: –40 … +85 °C storage; 0–60 °C operational

-

Weight: ≈ 1.56 kg (3.4 lb)

-

Certifications: CE, UL, RoHS, Zone-2 ready

Core Features & Customer Value

180-point density – One board replaces multiple smaller terminal blocks, freeing Mark V slots and reducing marshalling cabinet footprint

180-point density – One board replaces multiple smaller terminal blocks, freeing Mark V slots and reducing marshalling cabinet footprint

.

Multi-sensor compatibility – Accepts RTDs, thermocouples, 4-20 mA transmitters, and discrete contacts without external signal conditioners, cutting installation cost

.

On-board signal conditioning – Bridge completion, cold-junction compensation, and 250 Ω burdens are factory-installed, ensuring <0.1 % accuracy without user calibration

.

Passive, simple-device design – No firmware or battery; changes are made with jumpers and trim-pots, qualifying the card for safety-related systems without additional software V&V.

Zone-2 / marine certified – Conformal-coated PCB is certified for Class I Div. 2 and offshore environments, allowing direct installation in hazardous-location turbine skids without additional purge systems

GE IS200WETAH1AEC

.

Typical Applications

In combined-cycle power plants the DS200STBAG1ADC is installed in Mark V racks that monitor gas-turbine exhaust temperature (type-K thermocouples), bearing-metal temperature (3-wire RTDs), and fuel-pressure transmitters (4-20 mA). The 180-point density keeps the temperature-protection loop responsive while the on-board CJC resolves 0.1 °C changes

In combined-cycle power plants the DS200STBAG1ADC is installed in Mark V racks that monitor gas-turbine exhaust temperature (type-K thermocouples), bearing-metal temperature (3-wire RTDs), and fuel-pressure transmitters (4-20 mA). The 180-point density keeps the temperature-protection loop responsive while the on-board CJC resolves 0.1 °C changes

.

In pipeline compressor stations the same board reads 4-20 mA from suction/discharge pressure transmitters and drives auxiliary 24 V contactors, using the high-density layout to minimise marshalling cabinet footprint

.

Because the board is certified for marine environments, it is also used on off-shore platforms for well-head temperature and subsea pressure feedback without needing additional isolation barriers

.