Description

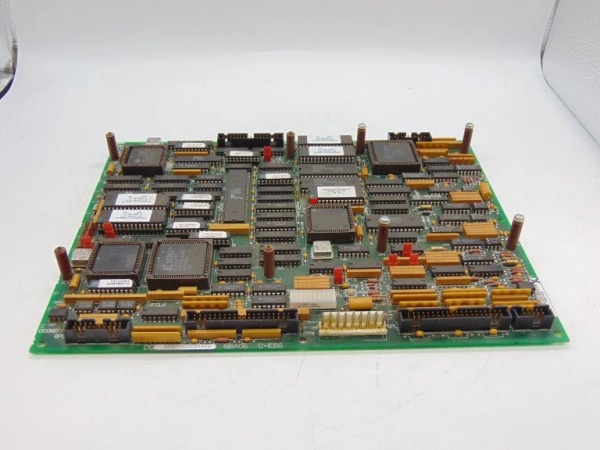

DS200SDCCG4A Product Overview

The DS200SDCCG4A is the main drive-control processor used inside GE Mark V Speedtronic and EX2000 medium-voltage variable-frequency drive cubicles. Occupying a single VME slot, the board contains three 16-bit microprocessors that share a common dual-port RAM, allowing concurrent execution of:

The DS200SDCCG4A is the main drive-control processor used inside GE Mark V Speedtronic and EX2000 medium-voltage variable-frequency drive cubicles. Occupying a single VME slot, the board contains three 16-bit microprocessors that share a common dual-port RAM, allowing concurrent execution of:

-

servo-position loops (fuel or IGV actuators)

-

high-speed digital I/O (contactors, limit switches)

-

analog I/O (±10 V, 4–20 mA pressure/flow transmitters)

In the automation hierarchy the card sits at the “primary controller” layer: it receives set-points from the triple-redundant Mark V CPU, closes current and position loops locally, and returns actual position plus diagnostics over the VME backplane. Because the processors are dual-ported, one CPU can handle math-intensive servo algorithms while another manages real-time I/O—keeping overall scan times below 1 ms even under heavy load

.

All field signals are routed through front-panel connectors (J1–J5) and are 1500 V isolated from the 5 V logic side, so 480 V contactor coils and 24 V sensors can be landed on the same card without ground-shift damage. The board is convection-cooled, carries a conformal coating, and is certified for Zone 2 hazardous locations, making it suitable for turbine skids, off-shore compressors, and pipeline booster stations where a fan-less, deterministic controller is mandatory

.

GE DS200SDCCG1A

Technical Specifications

-

Model Number: DS200SDCCG4A

-

Manufacturer: General Electric

-

Product Type: Primary Drive Control Board (SDCC functional acronym)

-

Processor Architecture: Triple 16-bit microprocessors (DCP + MCP + optional DSP) with dual-port RAM

-

I/O Capacity: High-speed digital I/O, ±10 V / 4–20 mA analog I/O, digital timer

-

Isolation: 1500 V working between field and logic

-

Connectors: 5 × front-panel headers (J1–J5) for I/O, gate-drive, and status

-

Power Consumption: +5 V @ 2 A typical, ±15 V for analog front-end

-

Operating Temperature: –30 … +65 °C (drive ambient)

-

Storage Temperature: –40 … +85 °C

-

Weight: ≈ 1 lb (0.45 kg)

-

Cooling: Convection (no fan required)

-

Certifications: CE, UL, RoHS, marine-environment conformal coating

Core Features & Customer Value

Triple 16-bit CPU with dual-port RAM – Concurrent execution of servo loops, I/O, and math functions keeps turbine or compressor control cycles deterministic even under heavy load

Triple 16-bit CPU with dual-port RAM – Concurrent execution of servo loops, I/O, and math functions keeps turbine or compressor control cycles deterministic even under heavy load

.

High-speed mixed I/O on one card – ±10 V servo commands, 4–20 mA transmitter loops, and 24 V contactor status are handled internally, eliminating external signal conditioners and reducing wiring errors.

1500 V isolation & surge immunity – TVS-protected inputs survive breaker-slam events common in medium-voltage drive cubicles, extending board life and reducing nuisance faults

.

Convection-cooled & Zone-2 ready – No fan required up to 65 °C; certified for Class I Div. 2 and offshore environments, allowing direct installation in hazardous-location turbine skids without additional HVAC

.

Drop-in spare – Shares the DS200 form factor with earlier SDCC revisions; no mounting changes, no parameter downloads, and no calibration required during swap-out.

GE DS200SDCCG1A

Typical Applications

In combined-cycle power plants the DS200SDCCG4A is installed as the main servo & I/O processor in Mark V drive cubicles that feed the gas-turbine compressor motor. It closes the current loop on the VFD while reading 4–20 mA from inlet-guide-vane positioners and driving 24 V contactors for auxiliary pumps—all on one card

In combined-cycle power plants the DS200SDCCG4A is installed as the main servo & I/O processor in Mark V drive cubicles that feed the gas-turbine compressor motor. It closes the current loop on the VFD while reading 4–20 mA from inlet-guide-vane positioners and driving 24 V contactors for auxiliary pumps—all on one card

.

In pipeline booster stations the same card is used in 4.16 kV VFDs that drive centrifugal compressors; the triple-CPU architecture keeps anti-surge valve response below 50 ms even when 500 I/O points are scanned continuously

.

Because the board is certified for marine environments, it is also used on off-shore platforms for well-boost compressors where a fan-less, deterministic, Zone-2 controller is mandatory .