Description

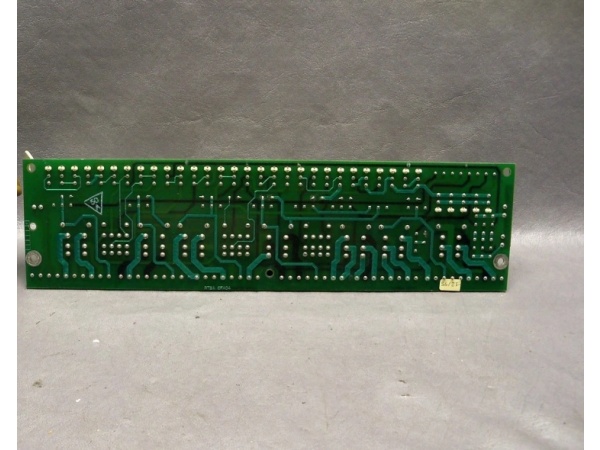

DS200RTBAG3AGC Product Overview

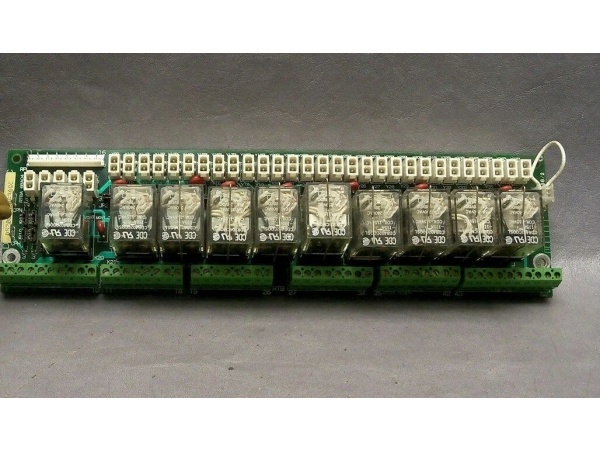

The DS200RTBAG3AGC is a “personality” relay terminal board used inside GE Mark V Speedtronic and EX2000 medium-voltage drive cubicles. It occupies a double-slot VME position and combines 10 high-current relays with 180 screw-clamp terminals, allowing the controller to drive auxiliary contactors, lock-out valves, indicator lamps, and other 115 VDC loads without external interposing hardware.

The DS200RTBAG3AGC is a “personality” relay terminal board used inside GE Mark V Speedtronic and EX2000 medium-voltage drive cubicles. It occupies a double-slot VME position and combines 10 high-current relays with 180 screw-clamp terminals, allowing the controller to drive auxiliary contactors, lock-out valves, indicator lamps, and other 115 VDC loads without external interposing hardware.

In the drive hierarchy the card sits at the “field-actuator” layer:

-

It receives 24 V logic commands from the triple-redundant CPU,

-

energises 115 VDC relay coils (K20–K29), and

-

returns contact-status feedback over the 16-pin RPL and 2-pin OPTPL connectors.

Each relay is manually configurable via front-panel jumpers: you can select internal 115 VDC coil feed (from the on-board bus) or external supply, and you can route contacts to either the local terminal strip or to remote cabinets through the pluggable Y31PL harness.

Because the board is conformal-coated and rated -40 … +85 °C, it survives the vibration, humidity, and conductive dust common in turbine compartments without additional HVAC.

Technical Specifications

-

Model Number: DS200RTBAG3AGC

-

Manufacturer: General Electric

-

Product Type: Relay Terminal Board (RTBA functional acronym)

-

Relays: 10 total (K20–K29) – 7 DPDT + 3 4PDT, 115 VDC coils

-

Coil Voltage: 115 VDC (±10 %)

-

Contact Rating: 3 A @ 125 VDC per pole (typical)

-

Connectors:

-

16-pin RPL (I/O to LTBA)

-

2-pin OPTPL (remote drive)

-

180 screw-clamp terminals for field wiring

-

-

Jumpers: 15 Berg-type jumpers for coil-source, Y31PL power, and contact routing

-

Isolation: 1500 V basic between field and logic

-

Power Supply: 24 VDC logic (backplane); 115 VDC coil (field or internal bus)

-

Status Indication: Individual green LEDs for each relay coil

-

Operating Temperature: 0–60 °C (drive ambient); –40 … +85 °C storage

-

Weight: ≈ 1.56 kg (3.4 lb)

-

Certifications: CE, UL, RoHS, Zone-2 ready

GE DS200RTBAG3AGC

Core Features & Customer Value

10-relay density – One card replaces multiple interposing relays, freeing Mark V slots and reducing spare-part count while keeping the same 115 VDC logic levels used throughout the turbine skid

10-relay density – One card replaces multiple interposing relays, freeing Mark V slots and reducing spare-part count while keeping the same 115 VDC logic levels used throughout the turbine skid

.

115 VDC coil rating – Matches legacy battery systems common in gas-turbine and compressor drives, eliminating the need for 24 V-to-125 V interposing relays.

180-point terminal strip – High-density screw-clamp layout keeps field wiring inside the cabinet, reducing marshalling errors and improving personnel safety during maintenance

.

15 jumper banks – On-board Berg jumpers allow you to select internal vs. external coil supply, remote vs. local contact routing, and Y31PL harness power without software tools, keeping commissioning time low

.

Zone-2 / marine certified – Conformal-coated PCB is certified for Class I Div. 2 and offshore environments, allowing direct installation in hazardous-location turbine skids without additional purge systems

.

Typical Applications

In combined-cycle power plants the DS200RTBAG3AGC is installed in Mark V drive cubicles that control auxiliary lube-pump contactors, cooling-fan contactors, and lock-out valves. The 115 VDC coil rating matches the plant’s DC battery, while the 10 relays give enough contacts for start permissives and alarm annunciation

In combined-cycle power plants the DS200RTBAG3AGC is installed in Mark V drive cubicles that control auxiliary lube-pump contactors, cooling-fan contactors, and lock-out valves. The 115 VDC coil rating matches the plant’s DC battery, while the 10 relays give enough contacts for start permissives and alarm annunciation

.

In pipeline booster stations the same card drives 115 VDC solenoid valves and remote indicator lamps, using the OPTPL connector to route signals to a remote marshalling cabinet without additional hardware

.

Because the board is certified for marine environments, it is also used on off-shore platforms for engine-driven generators where fan-less, Zone-2, 115 VDC relay control is mandatory

.