Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

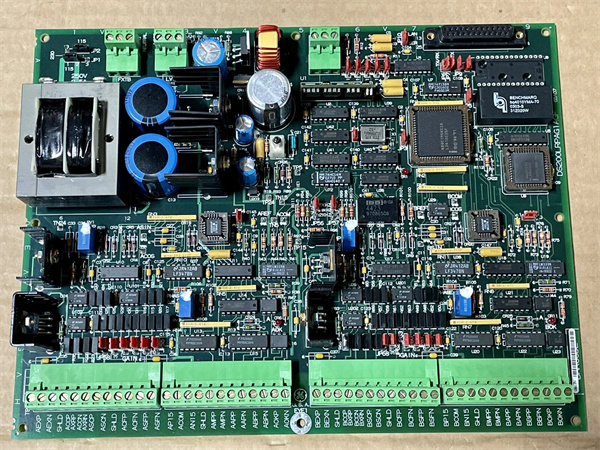

| Product model | GE DS200LRPAG1A |

| Manufacturer | General Electric (GE) Industrial Automation |

| Product category | Logic Relay & Protection Module (Mark VIe Series Compatibility) |

| Logic Inputs | 16 discrete digital inputs (24V DC sinking/sourcing); Response time: <1ms |

| Relay Outputs | 8 SPDT (Single-Pole Double-Throw) relays; 5A per pole @ 250V AC / 30V DC |

| Protection Functions | Overcurrent detection (configurable 0.5–10A); Short-circuit protection; Thermal overload monitoring |

| Communication Interface | RS-485 (Modbus RTU, 9600–115200 bps); SPI (for Mark VIe backplane integration) |

| Power Requirements | 24V DC (from Mark VIe backplane); Current draw: 0.4A typical, 0.6A peak (relay activation) |

| Physical Dimensions (H×W×D) | 135mm × 100mm × 32mm; Weight: 210g |

| Operating Temperature Range | -25°C to +70°C (ambient); -40°C to +85°C (short-term storage, <72h) |

| Environmental Protection | Conformal-coated PCB; 5%–95% RH (non-condensing); IP20-rated terminals |

| Configuration Tool | GE Proficy Machine Edition v9.0+ (logic programming, threshold setting) |

| Certifications | CE, UL 508C, IEC 61010-1, ATEX Zone 2, IEC 61508 (SIL 2 Compatible) |

| Compatibility | GE Mark VIe Control Systems; Industrial motors, pumps, conveyors; GE DS200DMCAG1A (motor control boards) |

DS200LRPAG1A

Product introduction

GE DS200LRPAG1A is a versatile logic relay & protection module engineered exclusively for GE’s Mark VIe control system, designed to unify logic programming, relay control, and equipment protection in industrial automation. Unlike standalone relays or basic protection modules, GE DS200LRPAG1A integrates three critical functions into one compact unit: discrete I/O handling, customizable logic (e.g., interlocks, timers), and real-time fault protection (overcurrent, short-circuit)—eliminating the need for multiple components in control cabinets.

In automation systems, GE DS200LRPAG1A acts as a “safety and control hub” for electromechanical devices like motors, pumps, and conveyors. For example, it uses its 16 digital inputs to monitor sensor signals (e.g., motor temperature, door interlocks) and executes preprogrammed logic to activate 8 relays—controlling equipment start/stop or triggering alarms. Its built-in protection functions also safeguard connected devices: if a pump draws excess current, GE DS200LRPAG1A trips the relay within 100ms, preventing motor burnout.

What sets GE DS200LRPAG1A apart is its seamless integration with Mark VIe. Via SPI and Modbus RTU, it syncs logic settings and fault data with the Mark VIe CPU, allowing operators to monitor and adjust parameters from a central HMI—no need for local programming tools. This integration, combined with its rugged design, makes GE DS200LRPAG1A ideal for mission-critical applications like power plant auxiliary systems or manufacturing production lines.

Core advantages and technical highlights

Integrated Logic + Protection for Simplified Design: GE DS200LRPAG1A eliminates the need to pair separate logic controllers and protection relays, reducing cabinet space by 30% and wiring complexity. In a food processing plant’s conveyor system, for example, it uses its 16 inputs to monitor conveyor speed sensors and safety door switches, then executes logic to: 1) Stop the conveyor if a door is open; 2) Trigger an alarm if speed drops below 1m/s; 3) Trip the relay if current exceeds 5A (indicating a jam). This all-in-one design cuts component costs by 25% compared to using three separate modules.

Fast Fault Response for Equipment Safety: GE DS200LRPAG1A’s overcurrent and short-circuit protection act within 100ms—faster than most generic relays (200–500ms). In a wastewater treatment plant’s pump system, this speed is critical: if a pump impeller jams, GE DS200LRPAG1A detects the current spike (from 2A to 8A) and shuts down the pump in 80ms, preventing winding damage that would cost $3,000 to repair. Unlike relays with fixed trip points, it lets users program custom current thresholds (0.5–10A) via Proficy Machine Edition, tailoring protection to specific motor ratings.

Seamless Mark VIe Data Sync: GE DS200LRPAG1A’s dual communication interfaces (SPI + RS-485) ensure real-time data flow with the Mark VIe system. SPI enables high-speed (up to 1Mbps) backplane communication for logic updates, while RS-485 sends fault logs to the HMI. In a power plant, this means operators can: 1) View relay status and current readings on the Mark VIe dashboard; 2) Adjust logic settings remotely (e.g., modify interlock conditions for a fuel pump); 3) Access historical fault data to diagnose recurring issues. This eliminates the need for on-site programming, saving 1–2 hours per maintenance visit.

Typical application scenarios

GE DS200LRPAG1A is a key component in a 500MW coal-fired power plant’s auxiliary control system, where it manages 8 lube oil pumps for turbine bearings. Each pump is connected to GE DS200LRPAG1A’s relay outputs, while inputs monitor pump motor current, bearing temperature, and oil pressure sensors.

The module’s preprogrammed logic ensures: 1) A pump starts only if oil pressure is >2 bar and the turbine is in “standby” mode; 2) If motor current exceeds 6A (indicating a jam), the relay trips immediately; 3) If temperature rises above 70°C, an alarm is sent to the Mark VIe HMI. During a 2024 maintenance cycle, GE DS200LRPAG1A detected a 7.2A current spike in Pump 3, tripping the relay in 90ms—preventing a bearing seizure that would have shut down the turbine for 12 hours (costing $1.2M in lost generation).

In a car manufacturing plant, GE DS200LRPAG1A controls robotic welding arm safety interlocks. Its inputs monitor light curtains and emergency stop buttons, while outputs disable the welding power supply if a worker enters the safety zone. The module’s Modbus connection to the Mark VIe HMI lets supervisors track interlock triggers, identifying bottlenecks in the production line and improving safety compliance.

Related model recommendations

GE DS200LRPBG1A: Upgraded variant of GE DS200LRPAG1A with 24 inputs/12 outputs (vs. 16/8); ideal for large-scale systems like assembly lines with multiple devices.

GE IC698CPE040-FJGE: Mark VIe CPU that communicates with GE DS200LRPAG1A via SPI; processes logic commands and displays real-time data on the HMI.

GE DS200DMCAG1A: Digital motor control board that pairs with GE DS200LRPAG1A; GE DS200LRPAG1A provides overcurrent protection, while GE DS200DMCAG1A regulates motor speed.

GE DS200EXPSG1A: 24V DC power supply module that delivers stable power to GE DS200LRPAG1A; ensures consistent relay performance during voltage fluctuations.

GE IS420YDIAS1B: Mark VIe digital input module that expands GE DS200LRPAG1A’s input capacity; adds 16 more channels for monitoring additional sensors.

GE Proficy Machine Edition v10.0: Configuration software for GE DS200LRPAG1A; used to program logic, set current thresholds, and troubleshoot faults.

GE DS200TERMG6: Terminal block kit for GE DS200LRPAG1A; includes shielded terminals and wire markers for organized wiring of inputs/outputs.

DS200LRPAG1A

Installation, commissioning and maintenance instructions

Installation preparation: Before installing GE DS200LRPAG1A, confirm compatibility with the Mark VIe chassis and target equipment (e.g., motors, pumps). Ensure the environment meets -25°C to +70°C and 5%–95% RH (non-condensing). Required tools: torque screwdriver (0.5–0.8 N·m), wire strippers (22–14 AWG), ESD-safe gloves, and a multimeter. Safety precautions: Power off the Mark VIe system and apply lockout/tagout. Mount GE DS200LRPAG1A in the chassis slot, secure with M4 screws, and connect power (24V DC) and I/O wires—use color-coded cables for inputs (blue) and outputs (red) to avoid wiring errors.

Maintenance suggestions: For daily operation, check GE DS200LRPAG1A’s LED indicators (green = normal, red = fault) via the Mark VIe HMI. Every 3 months, inspect relay contacts for arcing (signs of wear) and retorque terminal screws to 0.6 N·m. Test protection functions annually by simulating a current spike (using a variable current source) to confirm the relay trips within 100ms. If a relay fails, replace GE DS200LRPAG1A with a GE-approved spare—third-party modules may not match Mark VIe’s communication protocols or protection speed.

Service and guarantee commitment

GE DS200LRPAG1A is backed by a 48-month manufacturer’s warranty from GE, covering defects in materials, workmanship, and performance under normal industrial use (per UL 508C and IEC 61508 standards). If GE DS200LRPAG1A fails within the warranty period, GE provides a “rapid swap” service—pre-tested replacement modules are shipped within 48 hours for priority customers (e.g., power plants, manufacturing facilities) to minimize downtime.

GE offers 24/7 global technical support for GE DS200LRPAG1A, with specialists available via email or online portal to assist with logic programming, fault troubleshooting, or Mark VIe integration. Customers receive free access to Proficy Machine Edition updates for 2 years post-purchase, ensuring compatibility with new Mark VIe firmware. For enhanced reliability, GE’s Industrial Services team provides annual on-site inspections—verifying relay response time, input/output functionality, and communication links—reflecting GE’s commitment to keeping critical industrial systems safe and operational.