Description

DS200GSIAG1ACA Product Overview

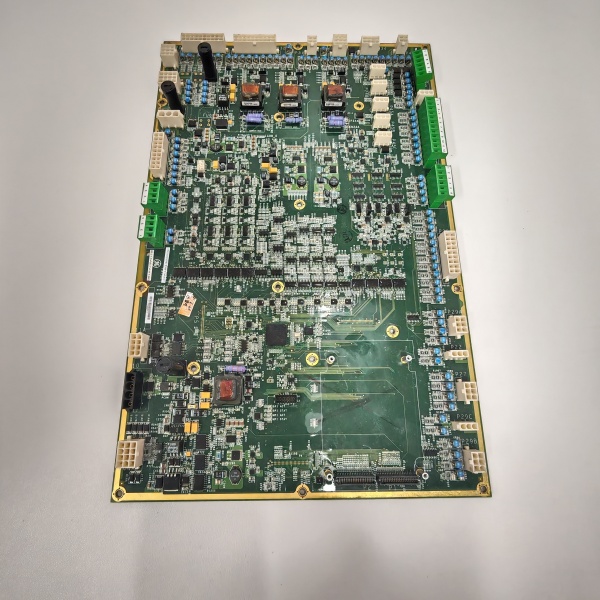

The DS200GSIAG1ACA is a “personality” printed-circuit board that installs inside GE Mark V Speedtronic medium-voltage drive cubicles. It serves two related functions:

The DS200GSIAG1ACA is a “personality” printed-circuit board that installs inside GE Mark V Speedtronic medium-voltage drive cubicles. It serves two related functions:

-

DC-bus regeneration – when the motor acts as a generator (e.g., during turbine compressor deceleration), the board routes excess DC energy back to the line-side converter or to an external braking resistor, preventing bus over-voltage.

-

IGBT snubber network – RC/RCD networks clamp dv/dt spikes generated during fast IGBT turn-off, extending semiconductor life and reducing EMI radiated into the control backplane.

The card is passive (no microprocessor) but houses six jumper banks and multiple trim-pots (PL, NL, U, V, W, PR, NR) that allow field technicians to fine-tune snubber damping or regeneration thresholds to match the installed IGBT module characteristics. Triple 40-pin and dual 16-pin keyed headers route gate-drive signals, fault feedback, and DC-bus voltage sampling between the power stack and the main control card.

Because the board is conformal-coated and certified for marine environments, it is widely used in gas-turbine compressor drives, off-shore platform VFDs, and pipeline booster stations where fan-less, high-dv/dt immunity is mandatory.

GE IS200WETAH1AEC

Technical Specifications

-

Model Number: DS200GSIAG1ACA

-

Manufacturer: General Electric

-

Product Type: Common DC Bus Regenerative / Snubber Interface Board

-

Function: DC-bus regeneration + dv/dt snubber for IGBT power stacks

-

Connectors: 3 × 40-pin Molex headers + 2 × 16-pin headers (keyed)

-

Trim Controls: 6 jumper banks + multi-turn pots (PL, NL, U, V, W, PR, NR) for damping/regen tuning

-

Snubber Elements: Foil capacitors & metal-film resistors (RC/RCD network)

-

Working Voltage: 1500 VDC typical (Mark V IGBT stack)

-

Isolation: Basic insulation; user must maintain IGBT safety clearances

-

Logic Supply: 24 VDC derived from Mark V backplane

-

Weight: ≈ 1.56 kg (3.4 lb)

-

Dimensions: 25 × 30 × 3 cm (approx.)

-

Temperature: –40 … +85 °C storage; 0–60 °C operational (drive ambient)

-

Coating: Standard GE Mark V conformal coating for humidity & contamination resistance

-

Certifications: CE, UL, RoHS, marine-environment ready

GE IS200WETAH1AEC

Core Features & Customer Value

Regeneration + snubber in one card – Eliminates separate braking resistors and external RC networks, saving panel space and wiring time while ensuring IGBT dv/dt compliance

Regeneration + snubber in one card – Eliminates separate braking resistors and external RC networks, saving panel space and wiring time while ensuring IGBT dv/dt compliance

.

Field-adjustable damping – Multi-turn pots let technicians fine-tune overshoot for different IGBT module types without removing the card, reducing commissioning time

.

Keyed high-density headers – Standard Mark V 40-pin and 16-pin connectors route gate-drive, DC-bus, and fault feedback in one plug, reducing wiring errors and vibration-related failures

.

Conformal-coated & marine-rated – Survives salt, humidity, and conductive dust common in off-shore compressor drives without additional enclosure pressurisation

.

Drop-in spare – Shares the DS200 form factor with earlier IAXS revisions; no mounting changes, no parameter downloads, and no calibration required during swap-out.

Typical Applications

In combined-cycle power plants the DS200IAXSG1A is installed in Mark V drive cubicles that feed the gas-turbine compressor motor. The snubber network clamps IGBT turn-off spikes, keeping EMI within IEEE 519 limits and extending IGBT lifetime beyond 100,000 hours

In combined-cycle power plants the DS200IAXSG1A is installed in Mark V drive cubicles that feed the gas-turbine compressor motor. The snubber network clamps IGBT turn-off spikes, keeping EMI within IEEE 519 limits and extending IGBT lifetime beyond 100,000 hours

.

In pipeline booster stations the same card is used in 4.16 kV VFDs that drive centrifugal compressors; the trim pots are adjusted on-site to match the installed 1700 V IGBT modules, ensuring <5 % overshoot during full-load switching

.

Because the board is certified for marine environments, it is also used on off-shore platforms for well-boost compressors where fan-less, high-dv/dt immunity is mandatory

.