Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | GE DS200DMCAG1A |

| Manufacturer | General Electric (GE) Industrial Automation |

| Product category | Digital Motor Control Interface Board (Mark VIe/EX2000 Compatibility) |

| Motor Type Support | 3-phase AC induction motors; 0.5kW – 50kW (0.7HP – 67HP) |

| Control Modes | V/F (Volts per Hertz), Sensorless Vector Control |

| Input Power Specifications | 24V DC (from Mark VIe backplane); 0.8A typical, 1.1A peak |

| I/O Configuration | 4 digital inputs (24V DC, sinking); 4 digital outputs (24V DC, 1A per channel); 2 analog inputs (4-20mA); 1 analog output (4-20mA) |

| Communication Protocols | RS-485 (Modbus RTU); GE SRTP (Secure Real-Time Protocol) for Mark VIe integration |

| Protection Features | Overcurrent detection, overload protection, phase loss monitoring, overheating alert |

| Physical Dimensions (H×W×D) | 130mm × 95mm × 32mm; Weight: 180g |

| Operating Temperature Range | -20°C to +65°C (ambient); -40°C to +85°C (short-term storage, <72h) |

| Certifications | CE, UL 508C, IEC 61800-5-1, RoHS 2 |

| Compatibility | GE Mark VIe Turbine Control Systems; GE EX2000 Excitation Systems; GE low-voltage motor drives |

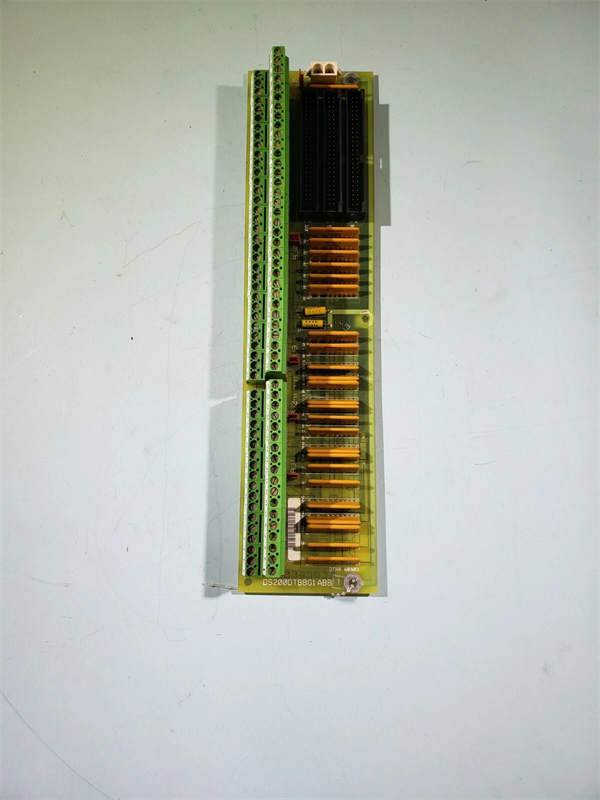

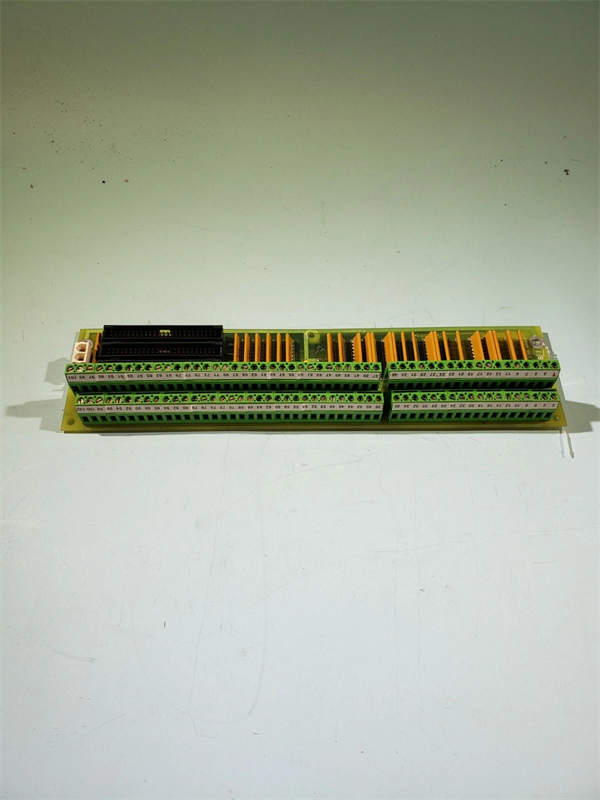

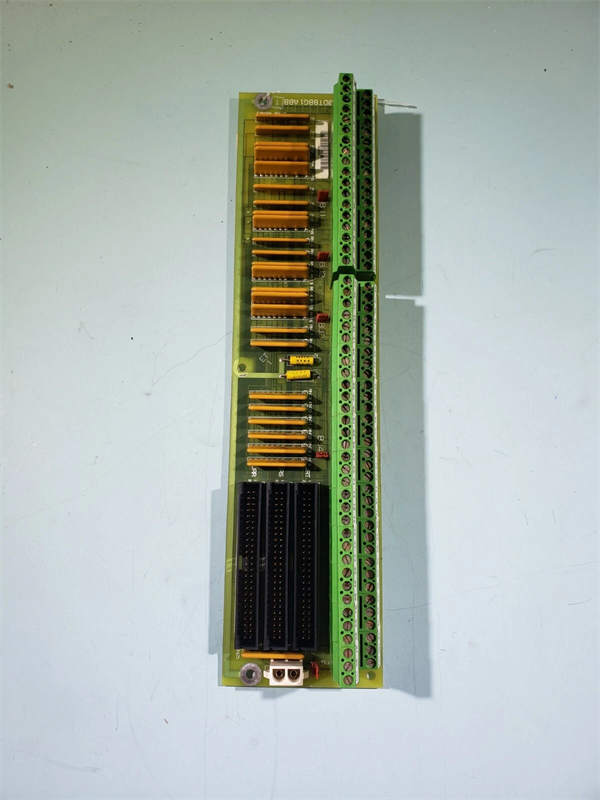

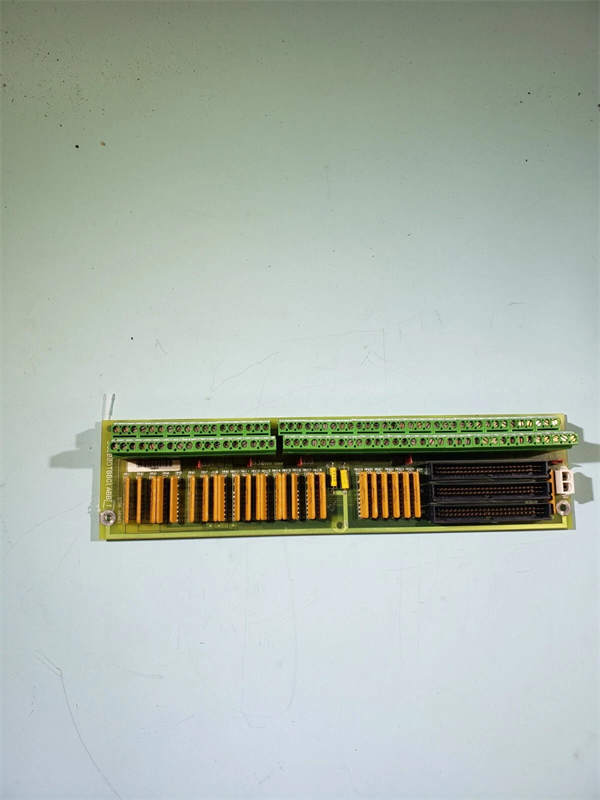

GE DS200DTBAG1A

Product introduction

GE DS200DMCAG1A is a compact, high-integration digital motor control interface board designed specifically for GE’s Mark VIe and EX2000 ecosystems, serving as a critical link between central control systems and low-to-medium power AC induction motors. Unlike standalone motor controllers, GE DS200DMCAG1A is engineered to integrate seamlessly with GE’s existing automation infrastructure—eliminating the need for third-party adapters and simplifying system architecture.

Its core function is to translate control commands from the Mark VIe CPU into precise motor operation, supporting both basic V/F control (for fans, pumps) and sensorless vector control (for variable-load applications like conveyors or mixers). By handling motor speed, torque, and protection logic locally, GE DS200DMCAG1A reduces data traffic to the central controller, improving overall system responsiveness.

In industrial settings—such as power plant auxiliary systems or manufacturing facilities—GE DS200DMCAG1A ensures reliable motor performance while enabling remote monitoring via Modbus or SRTP. Its compact form factor makes it ideal for space-constrained cabinets, and its robust protection features prevent motor damage from electrical faults or mechanical stress—directly lowering maintenance costs and unplanned downtime.

Core advantages and technical highlights

Seamless Mark VIe/EX2000 Integration: GE DS200DMCAG1A natively supports GE’s SRTP protocol, allowing it to communicate with Mark VIe CPUs (e.g., GE IC698CPE040-FJGE) in real time without additional gateways. This integration ensures consistent data exchange—for example, in a power plant’s lube oil pump system, the Mark VIe CPU sends speed setpoints to GE DS200DMCAG1A, which adjusts the pump motor and relays runtime data (current, temperature) back to the control system. This eliminates latency issues common with generic controllers, keeping auxiliary motors synchronized with turbine operations.

Dual Control Modes for Versatile Applications: GE DS200DMCAG1A offers both V/F and sensorless vector control, adapting to diverse motor loads without hardware reconfiguration. For simple applications like HVAC fans, V/F control provides stable, energy-efficient operation with minimal setup. For more dynamic tasks—such as adjusting the speed of a coal feeder in a power plant—sensorless vector control maintains precise torque even as load fluctuates, preventing material jams and ensuring consistent fuel delivery. This versatility means GE DS200DMCAG1A can replace two separate controllers, reducing cabinet space by 40% and simplifying inventory management.

Built-In Protection and Diagnostics: GE DS200DMCAG1A includes a suite of protective features tailored to industrial motor needs. Overcurrent detection triggers an immediate shutdown if motor current exceeds 150% of rated value, while phase loss monitoring alerts operators to wiring errors or component failure. Unique to GE DS200DMCAG1A is its overheating alert, which uses internal temperature sensors to warn of cabinet overheating before it impacts motor performance. In a food processing plant, this feature once alerted technicians to a clogged cooling fan—allowing them to resolve the issue before the motor overheated and disrupted production.

Typical application scenarios

GE DS200DMCAG1A is a staple in power plant auxiliary systems, where it controls 5kW–30kW motors for lube oil pumps, cooling fans, and fuel transfer pumps. In a 400MW steam turbine plant, GE DS200DMCAG1A is integrated with the Mark VIe system to manage the turbine’s lube oil pump motor: the Mark VIe CPU sends a speed setpoint based on turbine load, and GE DS200DMCAG1A adjusts the pump using sensorless vector control to maintain consistent oil pressure.

During a routine startup, the board’s phase loss monitoring detected a loose wire in the pump motor, triggering an alarm on the Mark VIe HMI. Technicians tightened the connection before the pump engaged, avoiding a catastrophic bearing failure that could have shut down the turbine for days. The board’s analog input also monitors oil temperature, relaying data to the Mark VIe system to activate a cooling valve (via GE DS200DMCAG1A’s digital output) if temperatures exceed 55°C.

In a manufacturing facility, GE DS200DMCAG1A controls 10kW conveyor motors for a packaging line. Using V/F control, it adjusts conveyor speed to match upstream production rates, while its Modbus interface allows the plant’s SCADA system to track runtime and energy usage. The board’s compact size fits easily in the conveyor’s control cabinet, and its RoHS compliance ensures it meets global environmental standards for electronics.

GE DS200DTBAG1A

Related model recommendations

GE IC698CPE040-FJGE: Mark VIe CPU that communicates with GE DS200DMCAG1A via SRTP; sends motor setpoints and receives runtime data for central control.

GE DS200EXPSG1A: 24V DC power supply module that provides stable power to GE DS200DMCAG1A; ensures consistent performance during voltage fluctuations.

GE DS200ITXDG1A: Turbine excitation interface module that works with GE DS200DMCAG1A in power plant systems; coordinates motor control with generator excitation.

GE 531X306H101: Encoder module (optional) for GE DS200DMCAG1A; adds closed-loop vector control capability for high-precision motor applications.

GE DS200TERMG5: Terminal block kit designed for GE DS200DMCAG1A; includes color-coded terminals and wire markers for organized field wiring.

GE DS200DMCBG1A: Higher-power variant of GE DS200DMCAG1A (up to 75kW); suitable for larger motors in heavy industrial applications like water pumps.

GE Proficy Machine Edition v10.0: Configuration software for GE DS200DMCAG1A; allows users to set control modes, adjust protection thresholds, and monitor diagnostics.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing GE DS200DMCAG1A, confirm compatibility with the target motor (0.5kW–50kW, 3-phase AC induction) and Mark VIe/EX2000 system. Ensure the mounting environment meets temperature (-20°C to +65°C) and humidity (5%–95% non-condensing) requirements. Required tools include a torque screwdriver (0.4–0.6 N·m for terminal blocks), wire strippers (22–14 AWG), ESD-safe gloves, and a multimeter. Safety precautions: Power off the Mark VIe system and apply lockout/tagout. Mount GE DS200DMCAG1A to the cabinet using M3 screws (torque: 0.8 N·m), ensuring 20mm clearance on all sides for ventilation. Connect the backplane connector to the Mark VIe chassis, and wire motor leads, power, and I/O to the terminal blocks—verify polarity and phase sequence to avoid damage.

Maintenance suggestions: For daily operation, check GE DS200DMCAG1A’s status LEDs (green = normal, red = fault) via the cabinet or Mark VIe HMI. Every 3 months, inspect terminal blocks for tightness (retorque to 0.5 N·m) and clean the board with a dry lint-free cloth. Calibrate analog inputs annually using a precision 4-20mA signal generator to ensure accurate load or temperature readings. If a fault occurs (e.g., overcurrent), first isolate the motor and test wiring; if the issue persists, use Proficy Machine Edition to review diagnostic logs. Replace GE DS200DMCAG1A with a GE-approved spare only if internal components fail—third-party replacements may compromise Mark VIe compatibility.

Service and guarantee commitment

GE DS200DMCAG1A is backed by a 48-month manufacturer’s warranty from General Electric, covering defects in materials, workmanship, and performance under normal industrial use (per UL 508C and IEC 61800-5-1 standards). If GE DS200DMCAG1A fails within the warranty period, GE provides a “rapid swap” service—pre-configured replacement units are shipped within 48 hours for priority customers (e.g., power utilities, manufacturing plants) to minimize downtime.

GE offers 24/7 global technical support for GE DS200DMCAG1A, with specialists available via email or online portal to assist with installation, configuration, and troubleshooting. Customers receive free access to Proficy Machine Edition software updates for 2 years post-purchase, ensuring compatibility with the latest Mark VIe firmware. For enhanced reliability, GE’s Industrial Services team provides annual on-site inspections—verifying communication links, I/O functionality, and protection settings—reflecting GE’s commitment to keeping critical motor control systems operational.