Description

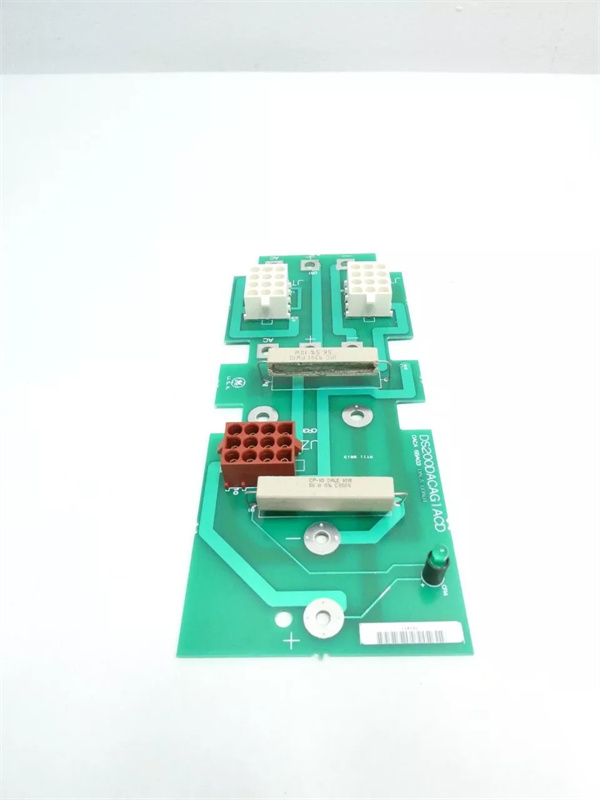

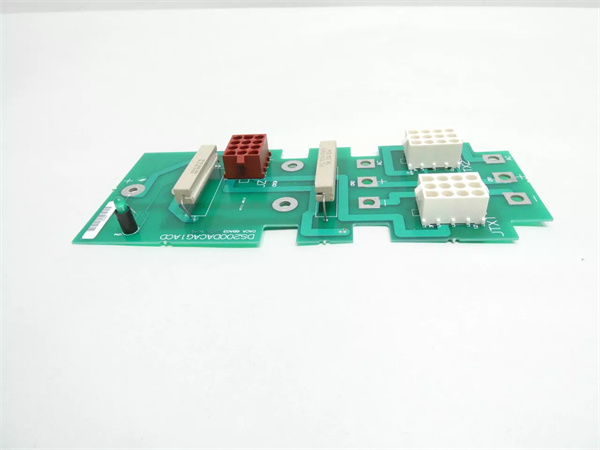

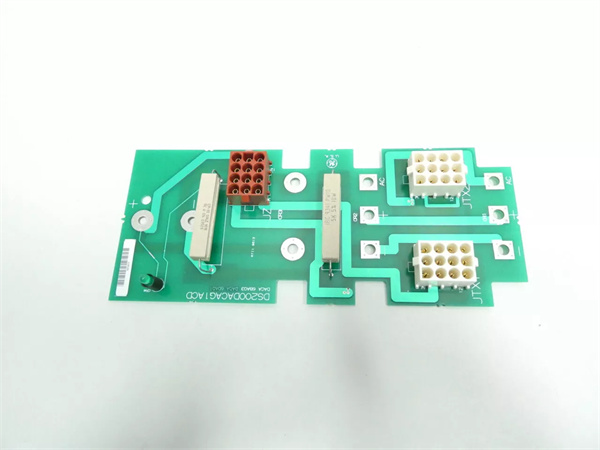

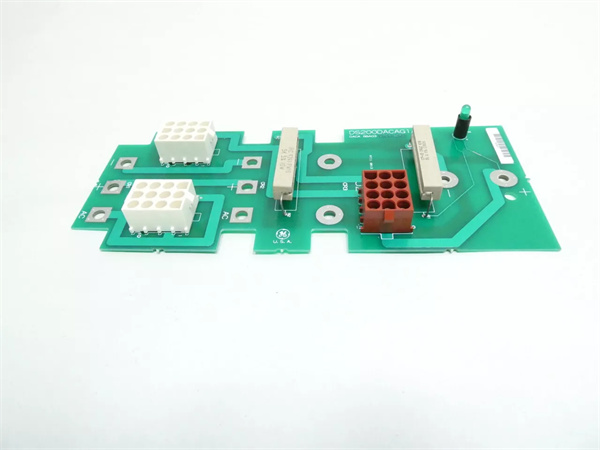

Professional Product Description: GE DS200DACAG1A Precision Digital-to-Analog Conversion Module

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | GE DS200DACAG1A |

| Manufacturer | General Electric (GE) Industrial Automation |

| Product category | Precision Digital-to-Analog (D/A) Conversion Module (Mark VIe Series) |

| Output Channels | 8 independent analog output channels (configurable per channel) |

| Output Signal Types | Voltage: 0–5V DC, 0–10V DC, ±5V DC, ±10V DC; Current: 4–20mA DC, 0–20mA DC |

| Conversion Accuracy | ±0.02% of full scale (at 25°C); ±0.05% of full scale (-25°C to +70°C) |

| Resolution | 16-bit (65,536 discrete levels) for all output types |

| Update Rate | 1ms per channel (simultaneous update capable via synchronization signal) |

| Input Interface | SPI (Mark VIe backplane, 1Mbps); Digital input for channel synchronization |

| Protection Features | Output short-circuit protection (current-limited to 30mA for voltage outputs); Over-temperature shutdown; ESD protection (±15kV contact) |

| Power Requirements | 24V DC (from Mark VIe backplane); Current draw: 0.4A typical, 0.6A peak |

| Physical Dimensions (H×W×D) | 130mm × 100mm × 32mm (slot-mount form factor); Weight: 180g |

| Operating Temperature Range | -25°C to +70°C (ambient); -40°C to +85°C (short-term storage, <72h) |

| Environmental Protection | Conformal-coated PCB (moisture/dust resistance); 5%–95% RH (non-condensing) |

| Calibration Support | Software-calibrated via GE Proficy Machine Edition; Factory-calibrated at 25°C |

| Certifications | CE, UL 508C, IEC 61010-1, ATEX Zone 2, IEC 61508 (SIL 2 Compatible) |

| Compatibility | GE Mark VIe Control Systems; GE IC698CPE040-FJGE (CPU); Industrial actuators, valves, drives; GE DS200ISCAG1A (signal conditioning) |

GE DS200DACAG1A

Product introduction

GE DS200DACAG1A is a high-precision digital-to-analog conversion module engineered exclusively for GE’s Mark VIe control system, serving as a critical link between digital control logic and analog field devices. Unlike generic D/A modules that lack system-specific integration, GE DS200DACAG1A is purpose-built to translate Mark VIe CPU’s digital commands into accurate analog signals—enabling precise control of valves, motors, and other analog actuators in industrial automation.

In control systems, GE DS200DACAG1A addresses a common pain point: the need for reliable, low-drift analog outputs to drive high-precision equipment. Its 8 independent channels (each configurable for voltage or current) eliminate the need for multiple single-channel modules, reducing cabinet space and wiring complexity. For example, in a chemical processing plant, GE DS200DACAG1A converts digital setpoints from the Mark VIe CPU into 4–20mA signals to adjust flow control valves—ensuring chemical mixing ratios stay within ±0.1% of target, a level of precision that generic modules often cannot achieve.

What distinguishes GE DS200DACAG1A is its combination of accuracy and flexibility: 16-bit resolution and ±0.02% full-scale accuracy meet the demands of mission-critical applications (e.g., turbine fuel control), while software-configurable outputs let users adapt the module to different actuator types without hardware changes. This versatility makes it a staple in both new Mark VIe installations and retrofits of older analog control systems.

Core advantages and technical highlights

Lab-Grade Accuracy for Critical Control Loops: GE DS200DACAG1A’s ±0.02% full-scale accuracy and 16-bit resolution ensure digital-to-analog conversion errors are negligible—critical for applications where small signal deviations cause large process variances. In a gas turbine fuel system, for instance, the Mark VIe CPU sends a digital command to GE DS200DACAG1A to adjust fuel flow; the module converts this to a 4–20mA signal that controls the fuel valve. With ±0.02% accuracy, the valve position error is less than 0.004mA (out of 16mA range), translating to a fuel flow deviation of <0.025%—preventing efficiency losses or emissions non-compliance. This accuracy outperforms generic 12-bit D/A modules (±0.1% error) by 80%.

Independent Channel Configuration for Mixed Applications: Each of GE DS200DACAG1A’s 8 channels can be individually set to voltage (e.g., ±10V for a servo motor) or current (e.g., 4–20mA for a valve) via GE Proficy Machine Edition—no hardware jumpers required. In a water treatment plant, this means one module can control: 1) A 4–20mA chemical dosing pump; 2) A 0–10V pH analyzer; 3) A ±5V stirrer motor—all from the same Mark VIe CPU. This eliminates the need for three separate modules, cutting component costs by 60% and reducing wiring time by 40% compared to mixed-vendor solutions.

Fast, Synchronized Updates for Time-Critical Systems: GE DS200DACAG1A supports 1ms per-channel update rates and simultaneous channel synchronization via a digital input—essential for systems where multiple actuators must respond in lockstep. In a robotics assembly line, for example, the Mark VIe CPU sends commands to three axes of a robotic arm; GE DS200DACAG1A synchronizes the 0–10V outputs for all three axes, ensuring movement is smooth and precise (no lag between axes). Without synchronization, axis lag could cause part misalignment and scrap rates of up to 5%; with GE DS200DACAG1A, scrap rates drop to <0.1%.

Typical application scenarios

GE DS200DACAG1A is a cornerstone of a 400MW combined-cycle power plant’s steam turbine control system, where it converts Mark VIe CPU digital commands into analog signals for 6 critical actuators: 1) 4–20mA for high-pressure steam valves; 2) ±10V for turbine speed governors; 3) 0–5V for lube oil pressure regulators. The module’s ±0.02% accuracy ensures steam valve positioning is precise within 0.004mA, maintaining turbine speed at 3600 RPM ±1 RPM—critical for grid frequency compliance (which requires ±0.1% speed stability).

During a grid load change (from 300MW to 400MW), the Mark VIe CPU updates the digital setpoints every 100ms; GE DS200DACAG1A converts these to analog signals in 1ms per channel, allowing the steam valves to adjust smoothly. This fast response prevents pressure spikes in the steam line, which could damage turbine blades and cost $500,000 in repairs. The module’s short-circuit protection also proved valuable when a valve actuator shorted: GE DS200DACAG1A limited current to 30mA, protecting the module and allowing the Mark VIe system to switch to a backup valve—avoiding a 2-hour shutdown.

In a pharmaceutical manufacturing plant, GE DS200DACAG1A controls 8 4–20mA peristaltic pumps for drug formulation. The module’s software calibration (via Proficy) ensures each pump’s flow rate is accurate within ±0.02%, meeting FDA requirements for dosage precision. The conformal-coated PCB also withstands the plant’s weekly washdowns (using sanitizing chemicals), maintaining reliability for over 3 years without maintenance.

Related model recommendations

GE DS200DACBG1A: Upgraded variant of GE DS200DACAG1A with 16 channels (vs. 8) and redundant power inputs; ideal for large-scale systems like refinery process units.

GE IC698CPE040-FJGE: Mark VIe CPU that sends digital setpoints to GE DS200DACAG1A via SPI; executes control logic for industrial processes.

GE DS200ISCAG1A: Intelligent signal conditioning module that pairs with GE DS200DACAG1A; conditions analog outputs for long-distance transmission (up to 1km) without signal degradation.

GE DS200EXPSG1A: 24V DC power supply module that provides stable power to GE DS200DACAG1A; ensures consistent conversion accuracy during voltage fluctuations.

GE IS420YDOAS1B: Mark VIe digital output module that works with GE DS200DACAG1A; adds discrete outputs for on/off control of auxiliary equipment (e.g., pump starters).

GE Proficy Machine Edition v10.0: Configuration software for GE DS200DACAG1A; used to set output types (voltage/current), calibrate channels, and enable synchronization.

GE DS200TERMG6: Terminal block kit for GE DS200DACAG1A; includes shielded terminals for analog outputs to minimize EMI interference.

GE DS200DDTBG2A: Digital I/O terminal board that organizes wiring for GE DS200DACAG1A; adds surge protection for output signals in harsh environments.

GE DS200DACAG1A

Installation, commissioning and maintenance instructions

Installation preparation: Before installing GE DS200DACAG1A, confirm compatibility with the Mark VIe chassis and target actuators (verify voltage/current requirements). Ensure the environment meets -25°C to +70°C and 5%–95% RH (non-condensing). Required tools: torque screwdriver (0.4–0.6 N·m), wire strippers (22–14 AWG), ESD-safe gloves, precision multimeter (for calibration), and shielded twisted-pair cable (for analog outputs). Safety precautions: Power off the Mark VIe system and apply lockout/tagout. Mount GE DS200DACAG1A in the chassis slot, secure with M4 screws, and connect SPI (backplane) and power cables—use separate cable runs for analog outputs and power to avoid EMI.

Maintenance suggestions: For daily operation, monitor GE DS200DACAG1A’s status LEDs (green = normal, red = fault/over-temperature) via the Mark VIe HMI. Calibrate channels annually using a precision signal generator: inject known digital setpoints and verify analog outputs match within ±0.02% of full scale. Inspect terminal blocks every 3 months for loose connections (retorque to 0.5 N·m) and clean the module with a dry lint-free cloth. If a channel fails, first test the actuator and wiring; if the issue persists, use Proficy to reset the module. Replace GE DS200DACAG1A with a GE-approved spare only if calibration fails or internal components are damaged—third-party modules may not meet SIL 2 accuracy requirements.

Service and guarantee commitment

GE DS200DACAG1A is backed by a 48-month manufacturer’s warranty from GE, covering defects in materials, workmanship, and performance under normal industrial use (per UL 508C and IEC 61508 standards). If GE DS200DACAG1A fails within the warranty period, GE provides a “rapid swap” service—pre-calibrated replacement modules are shipped within 48 hours for priority customers (e.g., power plants, pharmaceutical facilities) to minimize downtime.

GE offers 24/7 global technical support for GE DS200DACAG1A, with specialists trained in precision conversion systems available via email or online portal to assist with calibration, channel configuration, or troubleshooting. Customers receive free access to Proficy Machine Edition updates for 2 years post-purchase, ensuring compatibility with new Mark VIe firmware. For enhanced reliability, GE’s Industrial Services team provides annual on-site calibration verification of GE DS200DACAG1A—confirming accuracy, update rate, and synchronization performance—reflecting GE’s commitment to keeping critical control loops precise and reliable.