Description

Key Technical Specifications

-

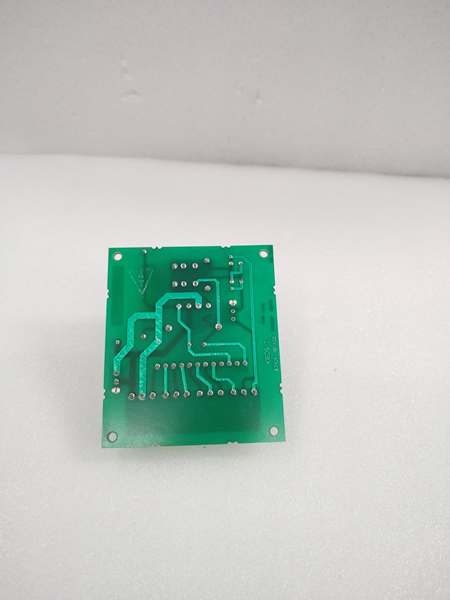

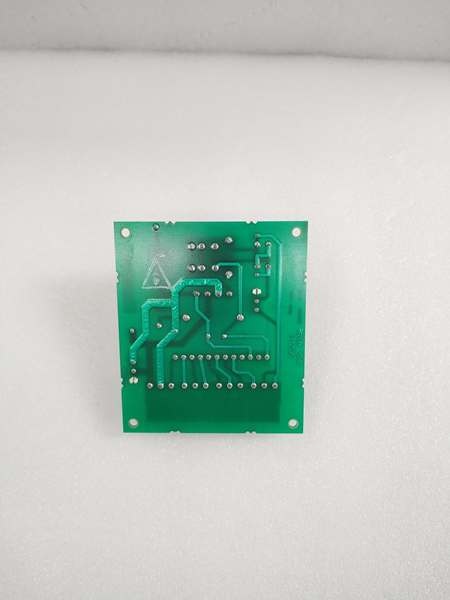

Model Number: DS200CPCAG1ABB

-

Manufacturer: General Electric

-

Functional Acronym: CPCA

-

Output Channels: 8 regulated 24 VDC, 2 A max per channel, 10 A total

-

Input Channels: 2 redundant 24 VDC feeds (18–30 VDC) from TPSA power supply

-

Isolation: 2500 Vrms ch-to-ch & field-to-logic

-

Operating Temperature: –40 °C to +70 °C

-

Protection: Short-circuit thermal shutdown, auto-reset overcurrent, 60 V over-volt clamp

-

Connectors: 1×12-pin, 2×2-pin, 4 pluggable terminal blocks (12 signal positions total)

-

Mounting: Single-slot VME rack, Mark V control cabinet

-

Diagnostics: Green/red LEDs per channel, load imbalance flag via backplane

-

Weight: 0.83 kg (1.83 lb)

GE DS200CPCAG1ABB

Field Application & Problem Solved

In a combined-cycle plant you can’t afford a contactor coil short pulling down the whole 24 V bus and tripping the unit. The CPCA card fixes that. It sits between the Mark V processor and the big contactors that drive fuel-trip solenoids, auxiliary motors, and cooling fans. Each of the eight outputs is current-limited and isolated, so when a coil shorts the card folds back, lights the red LED, and reports the fault over the backplane—plant stays online, operator sees exactly which coil died. You’ll find this board in every frame 5/6/9 gas-turbine row, usually in the middle rack right next to the TPSA supply. Its real value is letting you hot-swap a failed contactor without dropping logic power; the processor keeps running because the CPCA absorbs the abuse instead of the backplane.

In a combined-cycle plant you can’t afford a contactor coil short pulling down the whole 24 V bus and tripping the unit. The CPCA card fixes that. It sits between the Mark V processor and the big contactors that drive fuel-trip solenoids, auxiliary motors, and cooling fans. Each of the eight outputs is current-limited and isolated, so when a coil shorts the card folds back, lights the red LED, and reports the fault over the backplane—plant stays online, operator sees exactly which coil died. You’ll find this board in every frame 5/6/9 gas-turbine row, usually in the middle rack right next to the TPSA supply. Its real value is letting you hot-swap a failed contactor without dropping logic power; the processor keeps running because the CPCA absorbs the abuse instead of the backplane.

Installation & Maintenance Pitfalls (Expert Tips)

Back-plane screws too long—crack the relay

The tall 24 V relay on the component side clears the rack by millimeters. If you use the wrong screws the relay housing hits the steel first and the PCB cracks when you torque down. Always reuse the original shoulder screws or add a 2 mm nylon washer.

The tall 24 V relay on the component side clears the rack by millimeters. If you use the wrong screws the relay housing hits the steel first and the PCB cracks when you torque down. Always reuse the original shoulder screws or add a 2 mm nylon washer.

Forget the washers, crack the board

The four corner holes are through-plated. Cranking a steel washer straight against the epoxy will star-crack the board in a month of vibration. Use the fiber washers that shipped with the original—if they’re missing, steal them from the old card before you toss it.

The four corner holes are through-plated. Cranking a steel washer straight against the epoxy will star-crack the board in a month of vibration. Use the fiber washers that shipped with the original—if they’re missing, steal them from the old card before you toss it.

Coil spike kills the driver

Contactor coils are inductive beasts. The card has MOV snubbers, but on older installs the MOVs are tired. If you’re seeing nuisance over-volt faults, tack on an external flyback diode right at the contactor terminals—saves the driver and keeps the LED green.

Contactor coils are inductive beasts. The card has MOV snubbers, but on older installs the MOVs are tired. If you’re seeing nuisance over-volt faults, tack on an external flyback diode right at the contactor terminals—saves the driver and keeps the LED green.

Swap it hot anyway—label first

Mark V allows online replacement, but the CPCA connectors are identical side-by-side. Tag every wire with the terminal number before you pull the block; mixing up 24 V out and 0 V return will back-feed the card and blow the internal fuse—then you’re hunting a spare at 2 a.m.

Mark V allows online replacement, but the CPCA connectors are identical side-by-side. Tag every wire with the terminal number before you pull the block; mixing up 24 V out and 0 V return will back-feed the card and blow the internal fuse—then you’re hunting a spare at 2 a.m.

GE DS200CPCAG1ABB

Technical Deep Dive & Overview

The DS200CPCAG1ABB is basically an eight-channel, high-side smart switch. A small MCU on-board reads backplane commands, drives eight MOSFET stages, and reports current fold-back status. Each MOSFET sits behind a 2 A thermal limit and a 2500 V opto-isolator, so field faults never reach the Mark V logic. Two independent 24 V inputs (A and B) feed a diode-or; if one supply sags the other picks up without a hiccup. Output voltage is monitored in real time—if it collapses below 18 V while commanded on, the card flags “load imbalance,” telling the operator the coil is open or the wiring is shot. All of this rides a single VME-64X form factor so the card drops straight into legacy racks built in the late ’90s—no firmware flash, no dip-switch theatre, just slide, screw, and run.

The DS200CPCAG1ABB is basically an eight-channel, high-side smart switch. A small MCU on-board reads backplane commands, drives eight MOSFET stages, and reports current fold-back status. Each MOSFET sits behind a 2 A thermal limit and a 2500 V opto-isolator, so field faults never reach the Mark V logic. Two independent 24 V inputs (A and B) feed a diode-or; if one supply sags the other picks up without a hiccup. Output voltage is monitored in real time—if it collapses below 18 V while commanded on, the card flags “load imbalance,” telling the operator the coil is open or the wiring is shot. All of this rides a single VME-64X form factor so the card drops straight into legacy racks built in the late ’90s—no firmware flash, no dip-switch theatre, just slide, screw, and run.