Description

Parameter table

| Parameter name | Parameter value |

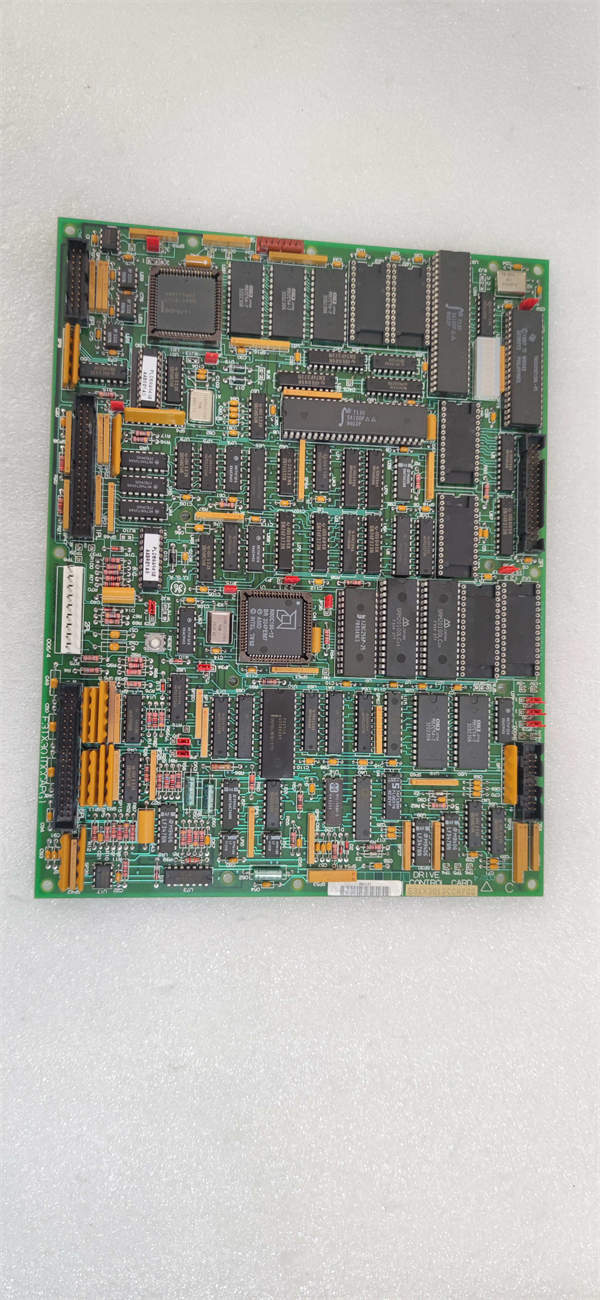

| Product model | 531X301DCCAFG2 |

| Manufacturer | General Electric (GE) |

| Product category | Control Module |

| Dimensions (approx.) | Compact design suitable for integration into control systems, specific dimensions in product manuals |

| Weight | Lightweight for easy installation and handling |

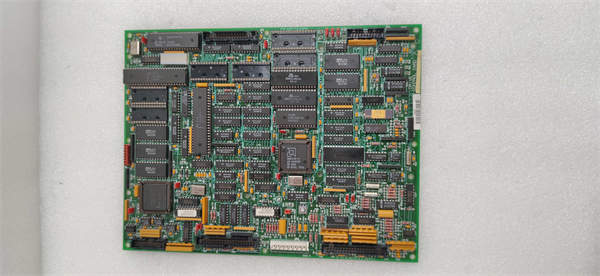

| Processor | High-performance processor for efficient data processing and control logic execution |

| Memory | Adequate memory for program storage and data logging, with expandable options |

| Communication interfaces | Supports multiple industrial communication protocols for seamless integration with other devices |

| I/O compatibility | Compatible with a range of digital and analog I/O modules for versatile connectivity |

| Operating temperature range | -40°C to +70°C, ensuring reliable operation in extreme industrial environments |

| Power supply | 24 V DC, compatible with standard industrial power systems |

| Certifications | Complies with international standards such as IEC and UL for quality and safety |

| Redundancy | Optional redundancy support for critical applications requiring high availability |

| LED indicators | Front-panel LEDs for power, communication, and system status monitoring |

GE 531X301DCCAFG2

Product introduction

The GE 531X301DCCAFG2 is a high-performance control module, a critical component in industrial automation and control systems. As part of GE’s extensive portfolio of industrial control products, it is designed to serve as a core processing unit, executing control logic and coordinating the operation of various devices in complex industrial processes.

This control module acts as a central hub, receiving input data from sensors and other monitoring devices, processing this information based on pre-programmed control algorithms, and generating output signals to control actuators, valves, motors, and other industrial equipment. It plays a vital role in ensuring the stability, efficiency, and safety of industrial operations by enabling precise control and real-time monitoring.

With its robust design and advanced features, the 531X301DCCAFG2 is well-suited for applications in industries such as oil and gas, power generation, chemical processing, and manufacturing. It can adapt to diverse operational requirements, making it a versatile solution for a wide range of industrial control scenarios.

Core advantages and technical highlights

Powerful processing capabilities: Equipped with a high-performance processor, the 531X301DCCAFG2 can quickly execute complex control logic and handle large volumes of data. This allows for real-time processing of input signals and rapid generation of output commands, ensuring timely responses to changes in industrial processes. For example, in a high-speed manufacturing line, the module can process sensor data related to product quality and adjust production parameters instantaneously to maintain consistent output.

Versatile communication: The module supports multiple industrial communication protocols, enabling seamless integration with other control systems, HMIs, SCADA systems, and intelligent devices. This ensures smooth data exchange and interoperability, facilitating the creation of a connected industrial ecosystem. Whether it’s communicating with a PLC on the factory floor or a remote monitoring system, the 531X301DCCAFG2 can transmit and receive data efficiently, enhancing operational visibility and control.

Extreme environment resilience: Designed to operate in harsh industrial conditions, the 531X301DCCAFG2 boasts an operating temperature range of -40°C to +70°C. It is also resistant to vibration, shock, and electromagnetic interference, ensuring reliable performance in challenging environments such as offshore oil platforms, desert power plants, and chemical factories. This durability minimizes downtime and reduces maintenance costs, even in the most demanding settings.

Flexible I/O integration: The module is compatible with a wide range of digital and analog I/O modules, allowing for flexible configuration based on specific application needs. This adaptability makes it suitable for both simple and complex control systems, from small-scale machinery control to large-scale industrial process automation. Users can easily expand the I/O capabilities by adding compatible modules, ensuring the system can grow with changing operational requirements.

Enhanced reliability with redundancy options: For critical applications where downtime is unacceptable, the 531X301DCCAFG2 offers optional redundancy support. In a redundant configuration, a backup module stands ready to take over in case of a primary module failure, ensuring uninterrupted operation. This feature is particularly valuable in industries such as power generation and oil refining, where even a brief disruption can lead to significant financial losses or safety risks.

Typical application scenarios

Oil and gas industry: In oil and gas exploration and production, the 531X301DCCAFG2 is used to control and monitor drilling operations, wellhead equipment, and pipeline systems. It can process data from pressure, temperature, and flow sensors to optimize drilling parameters, control valve operations to regulate fluid flow, and monitor equipment health to prevent failures. For example, in an offshore drilling platform, the module can adjust the operation of pumps and compressors based on real-time pressure readings, ensuring safe and efficient oil extraction.

Power generation facilities: In power plants, the module plays a key role in controlling turbine systems, boiler operations, and electrical distribution networks. It can monitor parameters such as steam pressure, temperature, and fuel flow, and adjust control valves and fuel supply systems to maintain optimal power generation efficiency. In a coal-fired power plant, the 531X301DCCAFG2 can regulate the feed rate of coal to the boiler based on electricity demand, ensuring stable power output while minimizing fuel consumption.

Chemical processing plants: In chemical manufacturing, precise control of reaction conditions is critical. The 531X301DCCAFG2 can control 搅拌器速度,heating/cooling systems, and raw material feed rates in chemical reactors. It processes data from pH sensors, temperature probes, and level indicators to maintain optimal reaction conditions, ensuring product quality and safety. For instance, in the production of fertilizers, the module can adjust the addition of chemicals based on real-time pH measurements, ensuring the final product meets strict quality standards.

Manufacturing automation: In manufacturing facilities, the module is used to coordinate the operation of production lines, robotic systems, and material handling equipment. It can control conveyor belt speeds, robotic arm movements, and machine tool operations to optimize production efficiency. In an automotive assembly plant, the 531X301DCCAFG2 can synchronize the activities of different workstations, ensuring that each component is installed in the correct sequence and at the right time, reducing production bottlenecks and improving overall productivity.

GE 531X301DCCAFG2

Comparison with related models in the series

Compared with other GE control modules: Other modules in GE’s control module series may differ in processing power, memory capacity, and communication capabilities. Lower-end models may be suitable for simple control tasks with limited I/O requirements, while the 531X301DCCAFG2, with its high-performance processor and versatile communication options, is better equipped for complex industrial applications. Higher-end models may offer advanced features such as built-in artificial intelligence for predictive maintenance or enhanced cybersecurity protocols, but the 531X301DCCAFG2 provides a balance of performance and cost-effectiveness for most standard to moderately complex control scenarios.

Compared with similar products from other brands: GE’s 531X301DCCAFG2 stands out due to its seamless integration with GE’s broader industrial automation ecosystem, including its I/O modules, HMIs, and software platforms. This integration simplifies system design, installation, and maintenance, reducing overall project complexity. The module’s extreme environment resilience also gives it an edge over many competing products, which may have more limited operating temperature ranges. Additionally, GE’s global service network ensures timely technical support and access to spare parts, which is crucial for minimizing downtime in industrial operations. The module’s flexibility in I/O integration and optional redundancy further enhance its competitiveness in the market.

Installation, commissioning and maintenance instructions

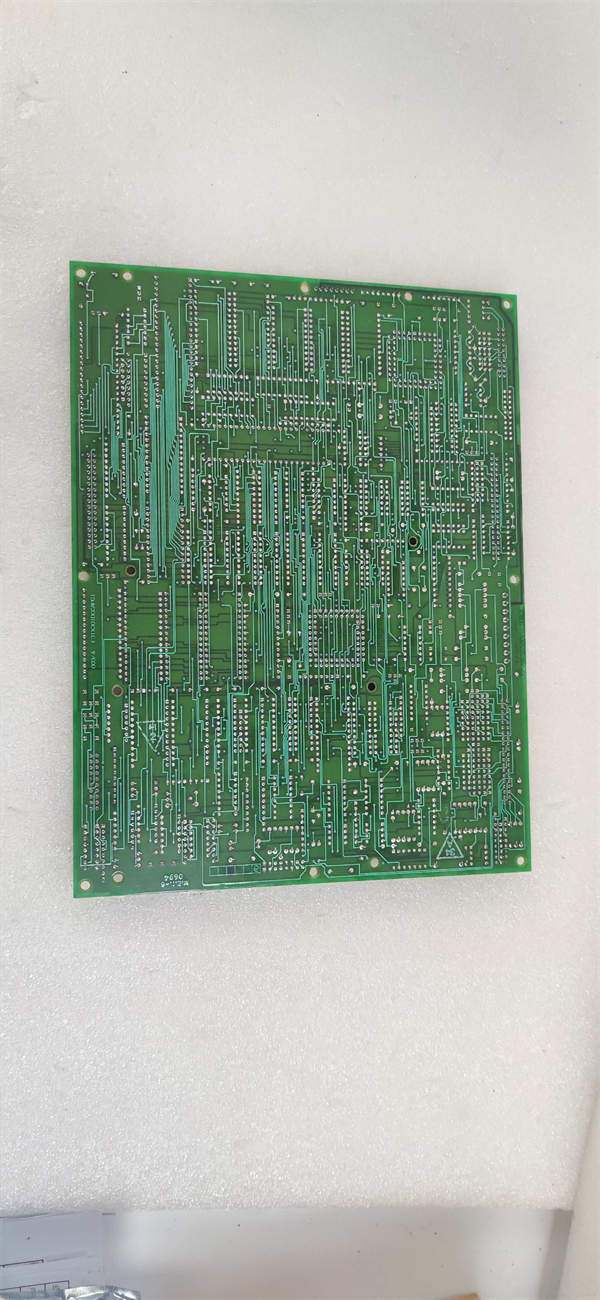

Installation preparation: Before installing the 531X301DCCAFG2, select a location that is clean, dry, and free from excessive vibration, dust, and corrosive substances. Ensure the mounting surface is sturdy enough to support the module and any connected components. Verify that the power supply meets the 24 V DC requirement and is properly grounded. Gather necessary tools such as screwdrivers, torque wrenches, and cable crimpers. Review the installation manual and wiring diagrams to familiarize yourself with the module’s connections and mounting specifications.

Commissioning process: Mount the module securely on the designated surface using appropriate fasteners. Connect the power supply cables, ensuring correct polarity and secure connections. Connect communication cables to the relevant interfaces, following the recommended wiring guidelines. Install and connect compatible I/O modules as needed, ensuring proper alignment and secure seating. Power on the module and check the front-panel LEDs to confirm power and communication status. Use GE’s configuration software to load the control program, configure communication parameters, and set up I/O mappings. Test the system by simulating various input conditions and verifying that the module generates the correct output signals. Monitor system performance for a period to ensure stable operation before full deployment.

Maintenance suggestions: Regularly inspect the 531X301DCCAFG2 for physical damage, loose connections, or signs of overheating. Clean the module’s surface and ventilation ports to prevent dust accumulation, which can impede cooling. Check the LED indicators periodically to monitor system status. Back up the control program and configuration data regularly to prevent loss in case of module failure. Update the module’s firmware to the latest version when available, using GE’s software tools, to benefit from performance improvements and security patches. If redundancy is enabled, test the failover functionality periodically to ensure it operates correctly. In case of faults, refer to the troubleshooting guide or contact GE’s technical support for assistance. Use only genuine GE spare parts for repairs to maintain system reliability.

Service and guarantee commitment

GE provides a standard warranty period for the 531X301DCCAFG2, covering manufacturing defects. Their global technical support team is available 24/7 to assist with installation, commissioning, and troubleshooting via phone, email, or online portals. Customers can access technical documentation, software updates, and training materials through GE’s online resources. For complex issues, GE’s field service engineers can be dispatched to provide on-site support. GE also offers extended warranty options and preventive maintenance services to ensure long-term reliability. Additionally, training programs are available to help customers maximize the module’s performance and troubleshoot common issues, ensuring optimal operation throughout its service life.