Description

Detailed Parameter Table

| Parameter name | Parameter value |

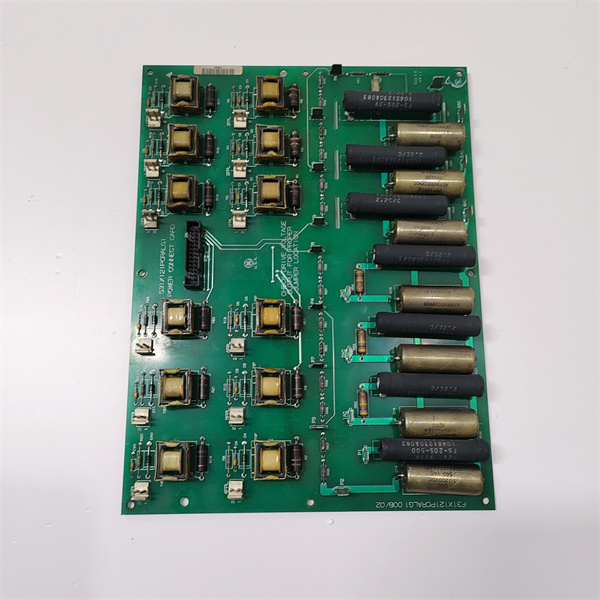

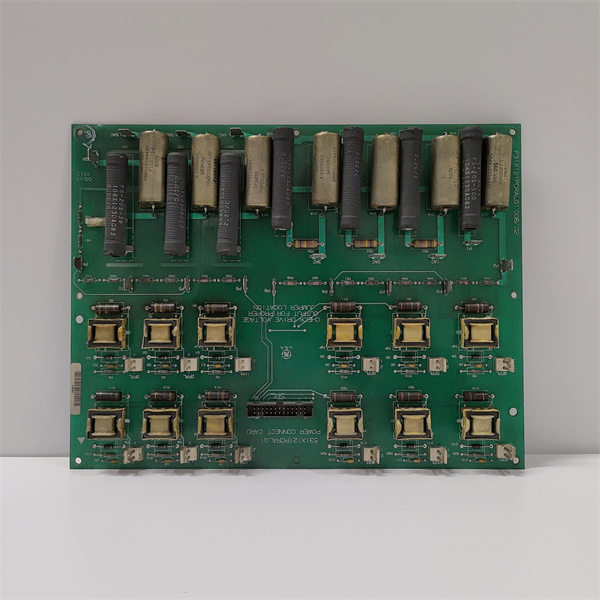

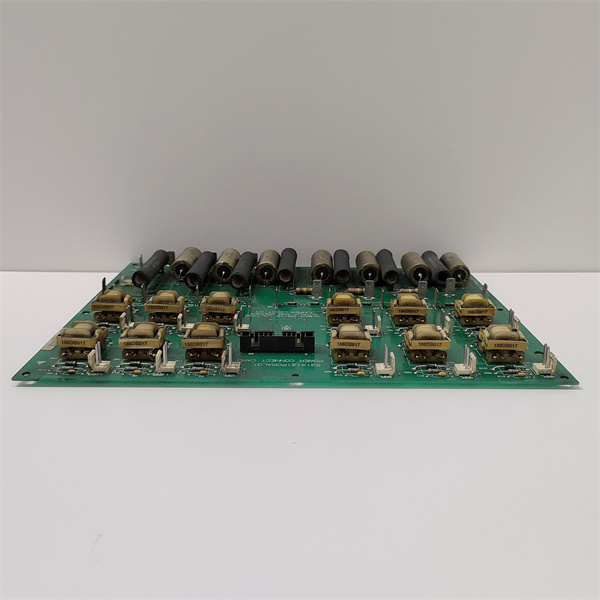

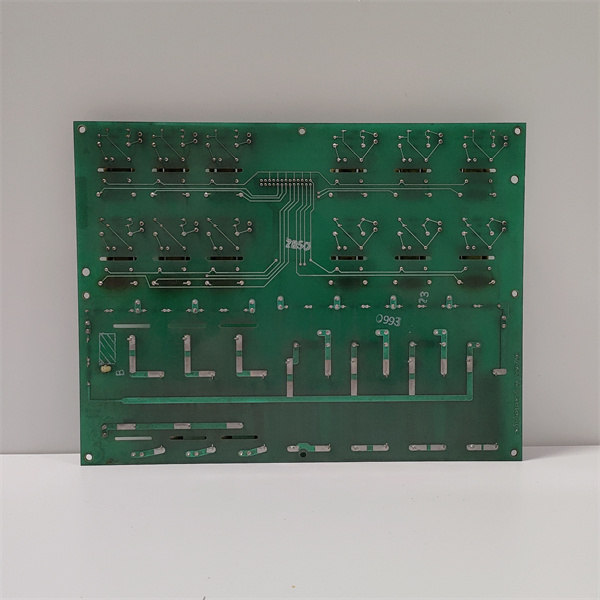

| Product model | 531X121PCRALG1 |

| Manufacturer | GE (General Electric) |

| Product category | Power Connection Board |

| Series compatibility | 531X Boards |

| Dimensions | 3.5 cm x 16 cm x 12.5 cm |

| Weight | 0.28 kg |

| Place of origin | USA |

| Certification | Co.CQ |

| Packaging details | New and original with factory sealed |

| Supply ability | 10 pieces a day |

| Compatibility | Compatible with multiple original equipment power connection boards in GE’s general – purpose drive systems, such as DC – 300 drive (verifiable through user guide or GE data sheets) |

| Diagnostic support | Troubleshooting the drive to check if the board is defective is facilitated by drive – available troubleshooting tools. These tools generate a detailed list of drive operation details for component failure identification and drive optimization |

GE 531X121PCRALG1

Product Introduction

The GE 531X121PCRALG1 is a power connection board designed and manufactured by General Electric. As part of the 531X Boards series, this board serves as a renewal part for multiple original equipment power connection boards. It plays a crucial role in establishing reliable power connections within industrial control systems, specifically in GE’s general – purpose drive systems.

This board is engineered to meet the demanding requirements of industrial environments, ensuring stable power transfer and compatibility with a range of equipment. With its well – defined dimensions of 3.5 cm x 16 cm x 12.5 cm and a weight of 0.28 kg, it is designed for easy integration into existing control setups. The factory – sealed packaging ensures that the board arrives in pristine condition, ready for installation.

Core Advantages and Technical Highlights

Compatibility and renewal function: The 531X121PCRALG1 offers the advantage of being a renewal part for multiple original power connection boards. This means that in cases where the original equipment power connection boards need replacement, the 531X121PCRALG1 can be used as a suitable substitute. It provides a cost – effective solution for maintaining and upgrading industrial control systems without the need to overhaul the entire power connection infrastructure.

Efficient troubleshooting: GE has designed the drive system in a way that troubleshooting to determine if the 531X121PCRALG1 board is defective is a straightforward process. The available troubleshooting tools within the drive can be accessed via the control panel. When these tools are run, they generate a comprehensive list of all the specific details regarding the drive’s operation. This list is invaluable for identifying components that have failed or are on the verge of failure. For example, in a manufacturing plant’s motor control system, if there are power – related issues, technicians can quickly use these diagnostic tools to pinpoint whether the 531X121PCRALG1 board is the source of the problem.

Typical Application Scenarios

Industrial drive systems: In a large – scale manufacturing facility, the GE 531X121PCRALG1 can be used in the power connection of motors within the production line. It ensures that the motors receive stable power, which is essential for their smooth operation. For instance, in an automotive assembly plant, where numerous motors power conveyor belts, robotic arms, and other machinery, the 531X121PCRALG1 can be installed in the drive systems of these motors. If any of the original power connection boards fail, the 531X121PCRALG1 can be easily replaced, minimizing production downtime.

Power – intensive industrial processes: In industries such as metalworking or mining, where heavy – duty equipment requires substantial power, the 531X121PCRALG1 can be integrated into the power connection systems of large – scale machinery. In a metal smelting plant, for example, the high – power electric furnaces and related equipment need reliable power connections. The 531X121PCRALG1 can be used to ensure that these power – hungry devices receive a stable power supply, contributing to the efficient operation of the entire smelting process.

GE 531X121PCRALG1

Related Model Recommendations

GE 531X121PCRAGG1: Another power connection board in the 531X series. It also serves as a replacement for multiple power connection boards but has different specifications for the DC armature voltage range. It uses two jumpers for configuration, which can be useful in applications where the voltage requirements need to be adjusted. In a power – generation – related application where the armature voltage may vary depending on the load, the 531X121PCRAGG1 could be considered as an alternative or supplementary board to the 531X121PCRALG1.

GE 531X175SSBAAM3: A dual – channel BIU interface circuit board. While it has a different function compared to the 531X121PCRALG1, in complex industrial control systems, it can work in tandem with the power connection board. For example, in a system where data communication and power management need to be coordinated, the 531X175SSBAAM3 can handle the data interface aspects, while the 531X121PCRALG1 takes care of the power connection requirements.

GE 531X304IBDARG1: A PC base drive card. It has components like crystal oscillators, metal brackets, and communication ports. In a multi – board industrial control setup, the 531X304IBDARG1 can communicate with the 531X121PCRALG1. In a motor control system, the 531X304IBDARG1 may process control signals and then use the 531X121PCRALG1 to ensure the proper power delivery to the motor based on those signals.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing the GE 531X121PCRALG1, ensure that the power to the drive system is completely turned off and isolated. Verify that the installation area is clean, free from dust, and has proper ventilation. Gather the necessary tools, such as a screwdriver for securing the board in place. Check the compatibility of the board with the existing equipment by referring to the user guide or GE data sheets. If the board is a replacement, carefully note the connections and configurations of the original board.

Maintenance suggestions: Regularly conduct visual inspections of the 531X121PCRALG1 to check for any signs of physical damage, such as cracks or burn marks. Look for loose connections or signs of overheating, like discolored components. Periodically use the drive’s diagnostic tools to check the functionality of the board. If any issues are detected, follow the troubleshooting procedures provided in the user manual. Keep the board clean by using compressed air to remove dust, especially from ventilation slots. Back up any configuration data related to the board in case a replacement becomes necessary.

Service and Guarantee Commitment

GE offers a [specify warranty period, e.g., 12 – month] warranty for the GE 531X121PCRALG1, covering manufacturing defects and component failures under normal operating conditions. The company’s global technical support team is available to assist customers with any technical issues. They can be reached via phone, email, or online chat. For more complex problems, on – site service can be arranged in major industrial regions.

Customers can access a range of resources, including user manuals, technical documentation, and firmware updates (if applicable), through GE’s industrial support portal. Training courses may be available to help technicians and system integrators understand the installation, configuration, and maintenance of the 531X121PCRALG1. For critical applications, GE may offer extended warranty plans that include priority support and preventive maintenance services, ensuring the long – term reliable operation of the board.