Description

Key Technical Specifications

-

Model Number: 469-P5-HI-A20

-

Manufacturer: GE Grid Solutions (Canada)

-

Control Power: 70-265 VAC, 48-62 Hz or 90-300 VDC, 15 W typical

-

Phase CT Secondary: 5 A (1 A option via set-point)

-

Ground CT: 5 A or 1 A (set-point)

-

Analog Outputs: 1 × 4-20 mA, ±1 % FS accuracy

-

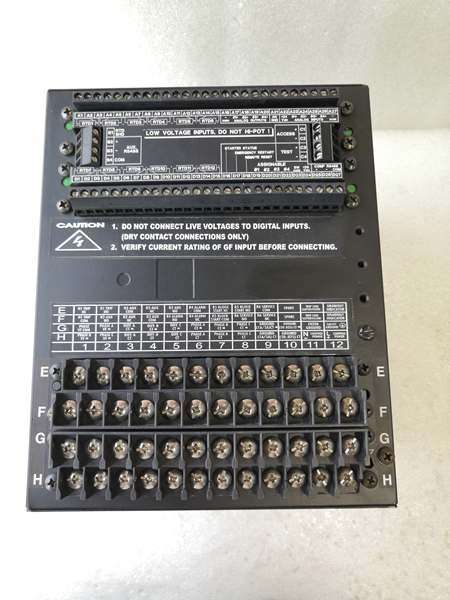

Digital I/O: 6 Form-C relay outputs (2 A, 250 VAC), 8 opto-isolated inputs (24-250 VAC/DC)

-

Communication: 1 × RS-232, 2 × RS-485 (Modbus RTU), optional 10Base-T Ethernet on “-E” suffix

-

Protection Functions: Thermal overload, jam/stall, unbalance, under/over-voltage, under/over-frequency, ground fault, RTD/thermistor overtemperature, phase reversal, acceleration timer

-

Timing Accuracy: ±0.5 %, 1–30 s delay in 1 s steps

-

Environmental: –40 °C to +70 °C operational, IP20 housing (IP54 with gasketed case)

-

Dimensions / Weight: 18.1 × 12.5 × 11.5 in, 20 lb (9 kg) in draw-out case

GE 469-P5-HI-A20

Field Application & Problem Solved

A 4 kV induced-draft fan doesn’t care about fancy algorithms—it wants a relay that will trip on overload before the motor cooks and give you a 4-20 mA feed to the DCS. The 469-P5-HI-A20 sits in the switchgear, reads 5 A secondaries from the CTs, and delivers thermal-overload, jam, unbalance and ground-fault protection in one box. When the card fails you lose all motor protection, the fan trips on “MOTOR FAULT” and the boiler backs out; swap the relay (draw-out case), set the CT ratio with the front keypad, and you’re back online in five minutes—no laptop required. Found in every medium-voltage MCC from pulp mills to combined-cycle plants; its value is bullet-proof repeatability: the overload curve is baked into EEPROM, so you get the same trip time the motor was commissioned with—critical for keeping old electromechanical breakers happy.

A 4 kV induced-draft fan doesn’t care about fancy algorithms—it wants a relay that will trip on overload before the motor cooks and give you a 4-20 mA feed to the DCS. The 469-P5-HI-A20 sits in the switchgear, reads 5 A secondaries from the CTs, and delivers thermal-overload, jam, unbalance and ground-fault protection in one box. When the card fails you lose all motor protection, the fan trips on “MOTOR FAULT” and the boiler backs out; swap the relay (draw-out case), set the CT ratio with the front keypad, and you’re back online in five minutes—no laptop required. Found in every medium-voltage MCC from pulp mills to combined-cycle plants; its value is bullet-proof repeatability: the overload curve is baked into EEPROM, so you get the same trip time the motor was commissioned with—critical for keeping old electromechanical breakers happy.

Installation & Maintenance Pitfalls (Expert Tips)

CT ratio mismatch—thermal element under-protects

The relay defaults to 5 A secondary. If you land on a 1 A CT and forget to change the setting the overload curve is 5× too high—motor cooks before the relay trips. Always verify CT primary/secondary in SETPOINTS > CURRENT before you energize.

The relay defaults to 5 A secondary. If you land on a 1 A CT and forget to change the setting the overload curve is 5× too high—motor cooks before the relay trips. Always verify CT primary/secondary in SETPOINTS > CURRENT before you energize.

Control-power dip—relay resets on starter inrush

The 90-300 VDC supply rides the same battery as the starter contactor. If the battery sags below 90 V during crank the relay reboots and you lose protection. Meter DC bus under crank; if it dips, add a separate 125 VDC feed or a small UPS.

The 90-300 VDC supply rides the same battery as the starter contactor. If the battery sags below 90 V during crank the relay reboots and you lose protection. Meter DC bus under crank; if it dips, add a separate 125 VDC feed or a small UPS.

RS-485 ground loop—communication drops out in storms

The two RS-485 ports are isolated, but if you tie shield drain at both ends you create a ground loop that glitches Modbus during lightning. Earth-ground the shield at the master only—float it at the relay.

The two RS-485 ports are isolated, but if you tie shield drain at both ends you create a ground loop that glitches Modbus during lightning. Earth-ground the shield at the master only—float it at the relay.

Draw-out case mis-racked—trip contacts don’t open

The case has a mechanical interlock; if you don’t rack the relay fully in the “CONNECT” position the Form-C contacts stay closed even when the LED says “TRIP.” Always rack until the white line aligns and the latch clicks—then tug-test.

The case has a mechanical interlock; if you don’t rack the relay fully in the “CONNECT” position the Form-C contacts stay closed even when the LED says “TRIP.” Always rack until the white line aligns and the latch clicks—then tug-test.

GE 469-P5-HI-A20

Technical Deep Dive & Overview

469-P5-HI-A20 is a microprocessor relay frozen in 1999 silicon. A 16-bit DSP runs the thermal model, samples CT/PT inputs at 3.2 kHz, drives six Form-C outputs, and talks Modbus RTU out the rear port. Because the curve library is in EEPROM you can swap the relay hot and the motor never knows—just open the CT shorting block first or you’ll arc-weld the test switch. Treat the 5 A CT inputs like precision shunts and the relay will keep the motor alive for another thirty years

469-P5-HI-A20 is a microprocessor relay frozen in 1999 silicon. A 16-bit DSP runs the thermal model, samples CT/PT inputs at 3.2 kHz, drives six Form-C outputs, and talks Modbus RTU out the rear port. Because the curve library is in EEPROM you can swap the relay hot and the motor never knows—just open the CT shorting block first or you’ll arc-weld the test switch. Treat the 5 A CT inputs like precision shunts and the relay will keep the motor alive for another thirty years

.