Description

Detailed Parameter Table

| Parameter name | Parameter value |

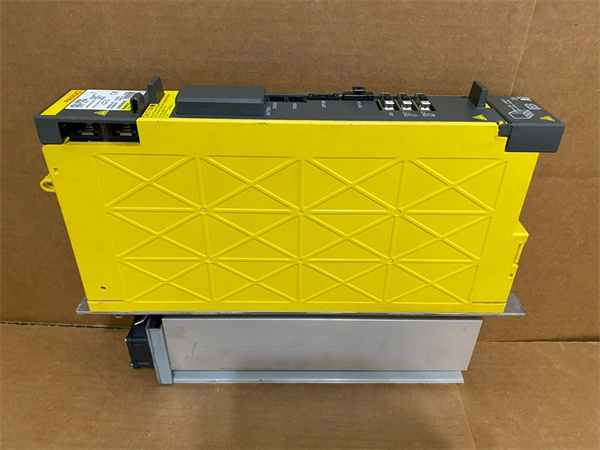

| Product model | A06B – 6117 – H208 |

| Manufacturer | FANUC |

| Product category | Servo amplifier |

| Power rating | Designed to power servo motors with specific torque and speed requirements, typically suitable for applications demanding medium – power servo control |

| Input voltage | Usually 3 – phase AC, with a voltage range optimized for compatibility with common industrial power supplies, often around 200 – 240 VAC (this may vary based on specific regional or application – specific configurations) |

| Output current | Capable of delivering an output current sufficient to drive servo motors effectively, with a rated output current value that aligns with the power and performance needs of the targeted servo motors, which could be in the range of several amperes depending on the motor it is paired with |

| Control interface | Equipped with advanced control interfaces to communicate with CNC (Computer Numerical Control) systems. Supports high – speed data transfer protocols to ensure precise and responsive control of servo motors. May include interfaces such as serial communication ports (RS – 232/RS – 485) or high – speed fieldbus interfaces like Ethernet – based protocols for seamless integration into modern automation setups |

| Protection features | Incorporates multiple protection mechanisms. Over – current protection safeguards against excessive current flow, which could damage the amplifier or connected servo motor. Over – voltage protection ensures that the amplifier remains operational even in the presence of transient voltage spikes in the power supply. Thermal protection is also in place to prevent overheating, automatically reducing power or shutting down the amplifier if the internal temperature exceeds safe limits |

| Dimensions | Compact and designed for easy integration into control cabinets. Specific dimensions are engineered to optimize space utilization, with a form factor that is compatible with standard industrial cabinet layouts. For example, it may have a width, height, and depth that allow for convenient mounting alongside other control components |

| Weight | Engineered to be lightweight without sacrificing durability, with a weight that is manageable during installation and maintenance. The weight is carefully balanced to ensure ease of handling while still providing a robust and reliable construction |

| Compatibility | Highly compatible with FANUC’s range of servo motors, ensuring seamless operation and optimal performance. Also designed to work in harmony with FANUC’s CNC systems, providing a comprehensive and integrated solution for industrial automation applications. However, it can also be integrated into some non – FANUC systems with appropriate interface adaptations |

FANUC A06B-6117-H208

Product Introduction

The FANUC A06B – 6117 – H208 is a high – performance servo amplifier, representing FANUC’s cutting – edge technology in the field of industrial automation. As a key component in motion control systems, this servo amplifier plays a pivotal role in driving servo motors with precision and efficiency.

FANUC, a globally renowned leader in CNC technology and industrial automation, has developed the A06B – 6117 – H208 with a focus on meeting the evolving demands of modern manufacturing. It is engineered to provide stable and accurate power to servo motors, enabling smooth and precise movement in various industrial applications. Whether in high – precision machining centers, robotic arms, or other automated machinery, the A06B – 6117 – H208 ensures that the servo motors operate at their best, translating into enhanced productivity and quality in industrial processes.

Core Advantages and Technical Highlights

High – Precision Motor Control

The A06B – 6117 – H208 is designed to deliver exceptional precision in servo motor control. It can accurately regulate the speed and torque of the servo motor, allowing for tight tolerances in applications that require highly accurate positioning. In a precision machining center, for example, the amplifier can precisely control the movement of the spindle and axes, ensuring that the cutting tool operates with micron – level accuracy. This high – precision control is achieved through advanced control algorithms and a high – speed signal processing unit, which can quickly respond to changes in the control commands from the CNC system.

Robust and Reliable Design

Constructed with high – quality materials and advanced manufacturing techniques, the A06B – 6117 – H208 offers robust and reliable performance. The enclosure is designed to protect the internal components from dust, moisture, and electromagnetic interference, making it suitable for use in harsh industrial environments. The high – quality capacitors, resistors, and power semiconductors used in the amplifier are selected for their long – term stability and durability. Additionally, the multiple protection features, such as over – current, over – voltage, and thermal protection, ensure that the amplifier can withstand abnormal operating conditions without suffering damage, minimizing downtime and maintenance costs.

Seamless Integration with FANUC Systems

One of the major advantages of the A06B – 6117 – H208 is its seamless integration with FANUC’s CNC systems and servo motors. FANUC has designed these components to work in harmony, ensuring optimal performance and compatibility. When used in a FANUC – based automation system, the amplifier can communicate efficiently with the CNC system, receiving and executing control commands with minimal latency. The compatibility with FANUC servo motors also allows for easy tuning and calibration, maximizing the overall performance of the motor – amplifier combination. This integration simplifies system design, installation, and maintenance, making it an ideal choice for FANUC – centric industrial setups.

Energy – Efficient Operation

In an era of increasing focus on energy efficiency, the A06B – 6117 – H208 is engineered to operate with high energy efficiency. It incorporates advanced power management techniques that reduce power consumption during operation. For instance, the amplifier can adjust the power output to the servo motor based on the actual load requirements, minimizing energy waste. This not only helps in reducing the overall energy costs of industrial operations but also contributes to a more sustainable and environmentally friendly manufacturing process.

Typical Application Scenarios

Machining Centers

In machining centers, the FANUC A06B – 6117 – H208 is used to drive the servo motors that control the movement of the spindle, X – axis, Y – axis, and Z – axis. The high – precision control of the amplifier enables the machining center to perform complex milling, drilling, and turning operations with extreme accuracy. For example, in the production of aerospace components, where tight tolerances are crucial, the A06B – 6117 – H208 ensures that the machining operations are carried out with the required precision, resulting in high – quality components. The robust design of the amplifier also ensures reliable operation in the harsh environment of a machining center, where there may be vibrations, dust, and electrical interference.

Robotics

In robotic applications, the A06B – 6117 – H208 is used to power the servo motors in robotic arms. The precise control of the amplifier allows the robotic arm to move with accuracy and repeatability, making it suitable for tasks such as pick – and – place operations in manufacturing plants or assembly lines. In an automotive assembly plant, robotic arms powered by this amplifier can accurately pick and place parts, ensuring efficient and error – free assembly. The seamless integration with FANUC’s control systems also enables easy programming and control of the robotic arms, enhancing the overall productivity of the robotic application.

Semiconductor Manufacturing

Semiconductor manufacturing requires extremely high – precision equipment. The A06B – 6117 – H208 is used in semiconductor manufacturing equipment to drive servo motors for wafer handling, lithography, and other critical processes. In lithography machines, which are used to pattern circuits on semiconductor wafers, the high – precision control of the amplifier is essential to ensure accurate alignment and patterning. The energy – efficient operation of the amplifier is also beneficial in semiconductor manufacturing, where large amounts of power are consumed, helping to reduce operational costs in these energy – intensive facilities.

FANUC A06B-6117-H208

Related Model Recommendations

FANUC Servo Motors: FANUC offers a range of servo motors that are specifically designed to work with the A06B – 6117 – H208. These motors, with their high – efficiency designs and compatibility with the amplifier’s control algorithms, can further optimize the overall performance of the motor – amplifier system. For applications where high – torque or precise speed control is required, selecting a compatible FANUC servo motor can enhance the effectiveness of the servo amplifier.

FANUC CNC Systems: Pairing the A06B – 6117 – H208 with FANUC’s CNC systems provides a comprehensive and integrated solution for industrial automation. The seamless communication and compatibility between the amplifier and the CNC system ensure smooth operation and easy programming. Different models of FANUC CNC systems offer varying levels of functionality, allowing users to choose the one that best suits their application requirements.

Power Supply Modules: To ensure stable and reliable operation of the A06B – 6117 – H208, FANUC also provides power supply modules that are specifically designed to work with this servo amplifier. These power supply modules can regulate the input voltage, providing a clean and stable power source for the amplifier. They also help in protecting the amplifier from voltage fluctuations and spikes, further enhancing the reliability of the overall system.

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installing the FANUC A06B – 6117 – H208, ensure that the installation location is clean, dry, and well – ventilated. The area should be free from excessive dust, moisture, and electromagnetic interference. Verify that the input voltage of the power supply matches the requirements of the amplifier. Tools required for installation include a screwdriver for securing the amplifier in place, a wire stripper for preparing the electrical connections, and a multimeter to check the electrical parameters. Disconnect all power sources before starting the installation to avoid electrical hazards. When connecting the amplifier to the servo motor and power supply, follow the wiring diagram provided in the product manual carefully to ensure correct connections.

Maintenance Suggestions

For routine maintenance of the A06B – 6117 – H208, perform visual inspections regularly. Check for any signs of physical damage, such as cracks on the enclosure or loose connections. Use compressed air to clean dust from the amplifier’s internal components, especially the cooling fins, to prevent overheating. Periodically test the amplifier’s functionality using diagnostic tools to verify servo motor control accuracy and check for any error messages. If communication or control issues arise, check the electrical connections, verify the input voltage, and ensure that the amplifier’s firmware is up to date (firmware updates can usually be obtained from FANUC’s official website). Replace any damaged cables or connectors promptly to maintain the integrity of the electrical connections. When replacing components, always use genuine FANUC parts to ensure compatibility and optimal performance.

Service and Guarantee Commitment

FANUC provides a comprehensive warranty for the A06B – 6117 – H208. The standard warranty typically covers manufacturing defects for a specified period, usually 12 – 24 months from the date of purchase, depending on the region and specific terms. During this warranty period, if the amplifier is found to be defective due to manufacturing issues, FANUC will repair or replace it free of charge. The company’s global technical support team is available to provide assistance with installation, configuration, and troubleshooting. Customers can access a wealth of online resources, including user manuals, installation guides, and technical bulletins, through FANUC’s official website. For critical applications, FANUC also offers extended warranty options and on – site support services to minimize downtime and ensure the long – term, reliable operation of the product. This commitment reflects FANUC’s confidence in the quality of the A06B – 6117 – H208 and its dedication to customer satisfaction.