Description

Detailed Parameter Table

| Parameter name | Parameter value |

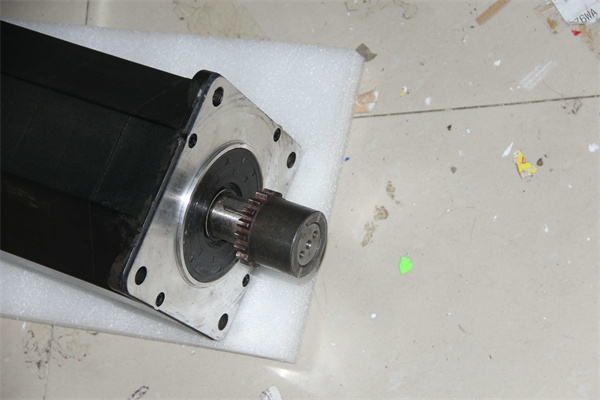

| Product model | A06B-0590-B004#7008 |

| Manufacturer | FANUC |

| Product category | Servo motor |

| Rated power | 1.5 kW |

| Rated voltage | 200 VAC (3-phase) |

| Rated current | 7.8 A |

| Rated speed | 3000 rpm |

| Maximum speed | 6000 rpm |

| Rated torque | 4.8 Nm |

| Maximum torque | 14.4 Nm (300% of rated torque) |

| Rotor inertia | 0.018 kg·m² |

| Feedback device | High-resolution absolute encoder (23-bit) |

| Protection class | IP65 (dust-tight and water jet resistant) |

| Cooling method | Natural air cooling |

| Dimensions (approx.) | 110 mm diameter × 220 mm length (excluding shaft) |

| Weight (approx.) | 5.8 kg |

| Shaft diameter | 14 mm |

| Keyway | Standard (6 mm width) |

FANUC A06B-0590-B004#7008

Product Introduction

The FANUC A06B-0590-B004#7008 is a high-performance servo motor, designed to deliver precise motion control in industrial automation applications. As a key component in FANUC’s extensive lineup of motion control products, this servo motor combines robust power with exceptional accuracy, making it a versatile solution for various manufacturing and robotics scenarios.

FANUC, a pioneer in CNC and servo technology, has engineered the A06B-0590-B004#7008 to work seamlessly with its servo amplifiers and CNC systems, forming an integrated motion control solution. Whether driving axes in machining centers, powering robotic joints, or controlling precision conveyors, this motor ensures smooth, repeatable motion with minimal latency. Its balanced design—blending power (1.5 kW) with compact dimensions—makes it suitable for applications where space is limited but performance cannot be compromised.

Core Advantages and Technical Highlights

High Dynamic Response

The A06B-0590-B004#7008 excels in dynamic performance, thanks to its low rotor inertia (0.018 kg·m²) and high torque-to-inertia ratio. This allows for rapid acceleration and deceleration, critical in applications like pick-and-place robotics where quick, precise movements are essential. For example, in an electronics assembly robot, the motor can swiftly transition from stationary to full speed (3000 rpm) and back, ensuring efficient handling of delicate components without delays.

Precision Positioning

Equipped with a 23-bit absolute encoder, the A06B-0590-B004#7008 delivers micron-level positioning accuracy. The encoder provides real-time position feedback to the servo amplifier, enabling closed-loop control that minimizes position error. In CNC machining, this precision ensures that cutting tools follow programmed paths with minimal deviation, resulting in parts with tight tolerances—vital for aerospace and medical device manufacturing.

Robust and Reliable Construction

Built to withstand harsh industrial environments, the A06B-0590-B004#7008 features an IP65 protection rating. This means it resists dust ingress and low-pressure water jets, making it suitable for use in machine shops, food processing facilities (with proper sealing), and outdoor installations. The motor’s natural air cooling design eliminates the need for external fans, reducing maintenance needs and failure points in dusty or humid conditions.

Seamless System Integration

Designed as part of FANUC’s ecosystem, the A06B-0590-B004#7008 integrates effortlessly with FANUC servo amplifiers (such as the A06B-6117 series) and CNC controllers. This compatibility simplifies setup, as the motor and amplifier automatically communicate parameters like rated current and feedback type, reducing configuration errors. The motor’s absolute encoder eliminates the need for homing sequences after power loss, saving time in production restart scenarios.

Typical Application Scenarios

CNC Machining Centers

In vertical machining centers, the FANUC A06B-0590-B004#7008 drives the X, Y, or Z axes, controlling the movement of the spindle or worktable. Its 3000 rpm rated speed and 4.8 Nm torque provide the power needed for cutting metal alloys, while its precision ensures that complex contours (like those in mold-making) are machined accurately. For example, when producing automotive engine components, the motor’s high dynamic response allows for rapid feed rate changes, reducing cycle times without sacrificing surface finish quality.

Industrial Robotics

Robotic arms in automotive assembly lines rely on the A06B-0590-B004#7008 to power joints responsible for welding, painting, or part handling. The motor’s maximum torque of 14.4 Nm enables it to lift heavy payloads (up to 10 kg in typical robotic configurations), while its low inertia ensures smooth, shake-free movement when positioning parts for assembly. In collaborative robots, its compact size and quiet operation make it ideal for working alongside human operators.

Automated Material Handling

In precision conveyor systems for electronics manufacturing, the A06B-0590-B004#7008 controls belt speed and positioning of PCBs or semiconductor wafers. Its accurate speed regulation (±0.1% of set speed) prevents damage to delicate components, while the absolute encoder ensures that parts are aligned correctly for inspection or processing. For example, in a wafer fabrication facility, the motor’s precision ensures that wafers are transported without vibration, avoiding defects during photolithography steps.

FANUC A06B-0590-B004#7008

Related Model Recommendations

FANUC A06B-6117-H208: A servo amplifier perfectly matched to the A06B-0590-B004#7008, providing 200 VAC output and advanced control algorithms to maximize motor performance.

FANUC A06B-0590-B005#7008: A higher-power variant (2.0 kW) of the same motor series, suitable for applications requiring increased torque while maintaining compatibility with the same amplifiers.

FANUC A860-2020-T301: A cable assembly designed for the A06B-0590-B004#7008, ensuring reliable signal transmission between the motor’s encoder and the servo amplifier.

FANUC i Series CNC Controllers: These controllers integrate seamlessly with the A06B-0590-B004#7008, enabling complex motion profiles and real-time monitoring in machining and robotics systems.

FANUC A06B-0227-B100: A lower-power servo motor (0.75 kW) from the same family, ideal for applications where the A06B-0590-B004#7008 provides more power than needed, maintaining system compatibility.

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installing the FANUC A06B-0590-B004#7008, ensure the mounting surface is flat, rigid, and capable of supporting the motor’s weight (5.8 kg). Clean the surface to remove debris that could cause vibration. Tools needed include a torque wrench (for mounting bolts), a shaft alignment tool, and a screwdriver for electrical connections. Verify that the power supply (via the servo amplifier) matches the motor’s 200 VAC rating. Use shielded cables for encoder and power connections to minimize electromagnetic interference. Align the motor shaft with the driven load (e.g., ball screw or gearbox) to within 0.1 mm axial and 0.05 mm radial runout to prevent premature bearing wear.

Maintenance Suggestions

For routine maintenance of the A06B-0590-B004#7008, inspect the motor quarterly for loose mounting bolts or damaged cables. Check the shaft seal for oil leaks (if coupled to a gearbox) and clean dust from cooling fins using compressed air. Monitor motor temperature during operation—if it exceeds 80°C (ambient + 40°C), investigate potential issues like overload or poor ventilation. Calibrate the encoder annually using FANUC’s diagnostic software to ensure position accuracy. If unusual noise or vibration occurs, check for misalignment or bearing wear; replace bearings only with genuine FANUC parts to maintain performance. Store spare motors in a dry environment with the shaft covered to prevent corrosion.

Service and Guarantee Commitment

FANUC backs the A06B-0590-B004#7008 with a 24-month warranty, covering manufacturing defects and material failures under normal operating conditions. During the warranty period, FANUC will repair or replace defective motors at no cost, including return shipping. The global technical support team offers 24/7 assistance for installation, troubleshooting, and calibration via phone, email, or remote diagnostics. Customers gain access to online resources such as installation manuals, maintenance guides, and firmware updates through FANUC’s portal. For critical applications, extended warranty options (up to 5 years) and on-site service contracts are available, ensuring minimal downtime. This commitment reflects FANUC’s confidence in the A06B-0590-B004#7008‘s reliability and its dedication to customer success in industrial automation.