Description

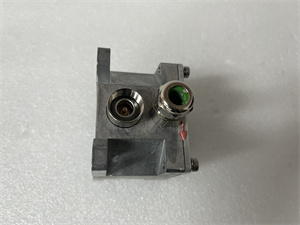

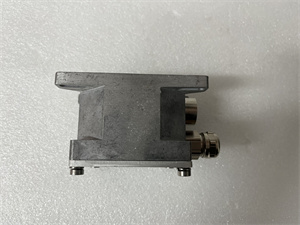

EPRO CON011 9200-00001 Eddy Current Signal Converter

1. Product Description

The EPRO CON011 9200-00001 is a high-precision eddy current signal converter designed for industrial machinery monitoring and non-destructive testing applications. As part of Emerson EPro’s MMS 6000 system, it converts raw eddy current signals from sensors (e.g., PR6422/…, PR6423/…, PR6426/…) into standardized analog or digital outputs, enabling real-time measurements of shaft displacement, vibration, oil film thickness, and more. Its robust design and compliance with international standards like API 670 and ISO 10817-1 make it a trusted choice for critical infrastructure in industries such as power generation, petrochemicals, and manufacturing.

The EPRO CON011 9200-00001 is a high-precision eddy current signal converter designed for industrial machinery monitoring and non-destructive testing applications. As part of Emerson EPro’s MMS 6000 system, it converts raw eddy current signals from sensors (e.g., PR6422/…, PR6423/…, PR6426/…) into standardized analog or digital outputs, enabling real-time measurements of shaft displacement, vibration, oil film thickness, and more. Its robust design and compliance with international standards like API 670 and ISO 10817-1 make it a trusted choice for critical infrastructure in industries such as power generation, petrochemicals, and manufacturing.

2. Key Technical Parameters

| Parameter | Specification |

|---|---|

| Input Type | Eddy current sensor signals (PR6422/…–PR6426/…) |

| Output Signal | Analog voltage (0–5V DC) or current (4–20mA) |

| Supply Voltage | 24V DC |

| Response Time | <15μs |

| Temperature Range | -20°C to 60°C (standard); extended options available |

| Communication | RS485 (optional) |

| Protection Class | IP65 (CON011) or IP67 (CON011/91) |

EPRO CON011 9200-00001

3. Advantages and Features

- Multi-Sensor Compatibility: Supports PR6422 to PR6426 sensors, covering measurement ranges from ±1mm to ±24mm.

- High Precision: Offers linearity ≤1.0% (with PR6423 sensors) and temperature drift <2%/100K, ensuring reliable performance in harsh conditions.

- Fast Response: <15μs response time for dynamic monitoring of rotating machinery.

- Explosion-Proof Option: Models like CON011/91 are certified for use in hazardous environments (EEx ib IIC T6).

- Modular Design: Easy integration with MMS 6000 systems and flexible installation via LEMO connectors or screw terminals.

4. Application Areas and Case Studies

Industries:

Industries:

- Power generation (turbines, generators)

- Petrochemical and oil/gas (compressors, pumps)

- Manufacturing (rotating equipment)

Case Study:

A major petrochemical plant in China reduced unplanned downtime by 30% by deploying EPRO CON011 9200-00001 with PR6423 sensors to monitor shaft alignment in compressors. The system’s real-time vibration analysis enabled predictive maintenance, preventing costly failures.

A major petrochemical plant in China reduced unplanned downtime by 30% by deploying EPRO CON011 9200-00001 with PR6423 sensors to monitor shaft alignment in compressors. The system’s real-time vibration analysis enabled predictive maintenance, preventing costly failures.

5. Competitor Comparison

Compared to generic signal converters, the EPRO CON011 9200-00001 offers:

Compared to generic signal converters, the EPRO CON011 9200-00001 offers:

- Wider Dynamic Range: Handles signals from 0–24mm displacement without additional modules.

- Simplified Calibration: Pre-programmed sensor profiles reduce setup time by 50%.

- Long-Term Stability: Advanced circuit design ensures ±0.1% annual drift, outperforming alternatives.

EPRO CON011 9200-00001

6. Selection Recommendations

- Sensor Compatibility: Verify sensor type (e.g., PR6423 for 8mm diameter targets) and measurement range.

- Environment: Choose IP67-rated CON011/91 for wet or dusty environments.

- Budget: Balance features like RS485 communication with project requirements.

7. Precautions

- Installation: Align sensors perpendicular to targets and shield cables from EMI.

- Calibration: Regularly validate accuracy using EPro-certified tools.

- Safety: In hazardous areas, use approved barriers (e.g., MTL5048) with CON011/91.