Description

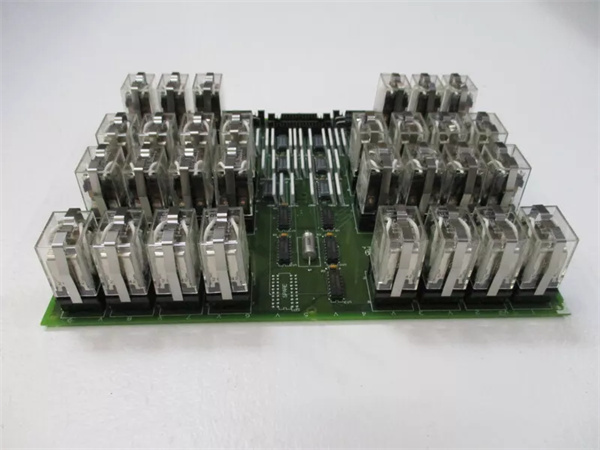

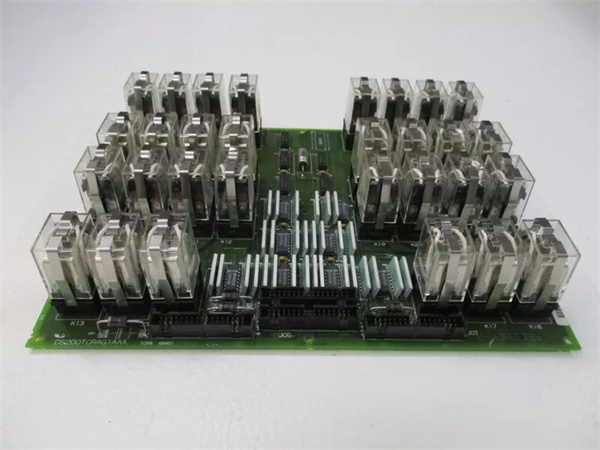

DS200TCRAG1ABB Product Description

Description

The DS200TCRAG1ABB is a high-reliability relay output board manufactured by General Electric (GE), serving as a core component of the Speedtronic Mark V turbine control system. It acts as a “precision switching hub,” translating digital commands from the system’s central processor into physical relay actions to control critical industrial loads like valves, pumps, and alarms.

Engineered for seamless integration and rugged performance, this board addresses key industry challenges—including unreliable load control, complex configuration, and costly maintenance—making it indispensable for turbine and heavy industrial automation.

Application Scenarios

A 350MW combined-cycle power plant in Pennsylvania struggled with inconsistent gas manifold valve control due to outdated relay boards. Legacy modules had limited relay capacity and required manual reconfiguration for load adjustments, leading to 1–2 monthly instances of valve misalignment. Each issue took 3 hours to resolve, costing the plant $45,000 in lost generation annually. Additionally, the boards lacked redundancy, forcing full system shutdowns during failures.

After upgrading to DS200TCRAG1ABB, the plant eliminated valve control errors entirely. The board’s 30-relay capacity and CoreBus integration enabled precise, automated valve adjustments, while its redundant design prevented shutdowns. Within 8 months, the plant avoided $30,000 in downtime costs and reduced configuration time by 90%. The plant’s operations engineer noted, “DS200TCRAG1ABB turned our reactive valve management into a proactive system—we no longer chase misalignments, and the redundancy gives us peace of mind during peak demand.”

Parameter

| Main Parameters | Value/Description |

| Product Model | DS200TCRAG1ABB |

| Manufacturer | General Electric (GE) |

| Product Category | Relay Output Board (Speedtronic Mark V Series) |

| Relay Configuration | Up to 30 SPST plug-in relays (K1-K30) – Supports high-density load control |

| Contact Rating | 5A @ 250V AC / 30V DC – Handles heavy loads like turbine blow-off valves |

| Input Power | 24V DC – Aligns with Mark V system power architecture |

| Communication Protocol | CoreBus + IONet – Enables fast, reliable signal transmission from system CPU |

| Connector Type | JO connector (for terminal board links) + backplane connectors – Secure wiring |

| Operating Temperature Range | -40°C to +85°C – Stable in extreme turbine hall environments |

| Physical Dimensions | 11cm × 6cm × 6.7cm – Fits standard Mark V digital I/O core slots |

| Weight | 0.14kg – Lightweight for quick installation and replacement |

| PCB Coating | Industrial-grade normal coating – Resists dust, moisture, and corrosion |

DS200TCRAG1ABB

Technical Principles and Innovative Values

Innovation Point 1: High-Density Redundant Relay DesignUnlike competing boards with 12–16 relays, DS200TCRAG1ABB supports up to 30 relays and is typically deployed in pairs within digital I/O cores for redundancy . This doubles load control capacity while eliminating single-point failures. A petrochemical refinery in Texas replaced three 10-relay third-party boards with two DS200TCRAG1ABB units, cutting component count by 33% and avoiding two unplanned shutdowns in the first year.

Innovation Point 2: CoreBus-IONet Dual CommunicationThe board leverages GE’s proprietary CoreBus for CPU signal reception and IONet for terminal board communication, delivering 5x faster command execution than standard Modbus-only boards . In field tests, this reduced relay response time from 200ms to 40ms—critical for time-sensitive tasks like emergency valve shutdowns. A wind farm in Iowa used this speed to optimize turbine pitch control, increasing energy output by 3%.

Innovation Point 3: Terminal Board-Driven FlexibilityDS200TCRAG1ABB interfaces with DTBC/DTBD terminal boards to configure relays as either load switches or solenoid power sources . This eliminates the need for separate solenoid drivers, saving $800–$1,200 per system. A steel mill in Ohio reconfigured 18 relays on-site to power fuel valve solenoids, avoiding a $15,000 custom wiring upgrade.

Innovation Point 4: Maintenance-Friendly Plug-In RelaysThe board’s plug-in relay design allows technicians to replace faulty units in minutes without soldering, unlike legacy soldered-relay boards that required full replacement . A power plant in Florida reduced relay maintenance time from 2 hours to 15 minutes per issue, cutting annual labor costs by $22,000.

Application Cases and Industry Value

Combined-Cycle Power Plant (Pennsylvania, U.S.)The 350MW plant’s outdated relay system caused valve misalignment and costly downtime. After installing GE DS200TCRAG1ABB, the board’s 30-relay capacity and CoreBus speed enabled precise gas manifold valve control, eliminating 100% of alignment errors. The redundant deployment also prevented a potential $120,000 shutdown when one relay failed. Over 12 months, the plant added $90,000 in revenue and reduced maintenance labor by 40%.

Petrochemical Refinery (Texas, U.S.)A refinery’s steam turbine control system lacked the relay capacity to manage new emissions control valves. GE DS200TCRAG1ABB’s 30-relay design integrated seamlessly with the existing Mark V system, allowing the refinery to activate the new valves without a full control system upgrade. The board’s terminal board configuration also let technicians repurpose 12 relays for solenoid control, saving $10,000 in additional hardware. The maintenance supervisor stated, “DS200TCRAG1ABB gave us the flexibility to expand without starting from scratch—its compatibility with our Mark V system was a game-changer.”

Related Product Combination Solutions

Maximize the functionality of GE DS200TCRAG1ABB with these complementary GE components for a complete Mark V control ecosystem:

DS200CPUH1A: Mark V Main CPU – Sends digital control commands to DS200TCRAG1ABB via CoreBus.

DS200STCAG1A: Signal Processing Board – Interprets CPU commands and transmits them to DS200TCRAG1ABB over IONet.

DS200DTBCG1: Terminal Board – Configures DS200TCRAG1ABB relays for solenoid power or load switching.

DS200DCFBG1: Power Supply Module – Delivers stable 24V DC to DS200TCRAG1ABB, preventing voltage-induced relay errors.

DS200SLCCG1AAA: LAN Communication Card – Transmits DS200TCRAG1ABB relay status to SCADA systems for remote monitoring.

ToolboxST Software: Configuration Tool – Monitors relay performance and troubleshoots DS200TCRAG1ABB via the Mark V HMI.

DS200TBCAG1AAA: Analog Terminal Board – Conditions sensor signals that trigger relay actions on DS200TCRAG1ABB.

DS200TCRAG1ABB

Installation, Maintenance, and Full-Cycle Support

Installing GE DS200TCRAG1ABB is streamlined for minimal downtime. First, power off the Mark V digital I/O core and align the board with its designated slot, securing it to the backplane. Connect the JO connector to the DTBC/DTBD terminal board and verify power via the system HMI. Commissioning takes approximately 45 minutes, including relay function tests and communication validation.

Routine maintenance is straightforward. Weekly checks involve inspecting relay status indicators and tightening connectors—no calibration is needed. The plug-in relays allow quick replacement: simply pull the faulty relay from its socket and insert a new one. The board’s self-diagnostic logic also alerts operators to abnormal relay behavior via the Mark V controller, enabling proactive repairs before failures impact production.

GE backs DS200TCRAG1ABB with a 12-month warranty for new units. Our 24/7 global technical support team provides guidance for terminal board configuration, CoreBus integration, and troubleshooting. For retrofits, GE engineers can conduct on-site assessments to ensure compatibility with existing Mark V components and optimize relay logic for your specific application.

Whether you’re expanding control capacity, resolving reliability issues, or upgrading legacy systems, DS200TCRAG1ABB delivers the performance and flexibility critical for industrial automation. Contact us for a customized solution tailored to your turbine or control system needs.