Description

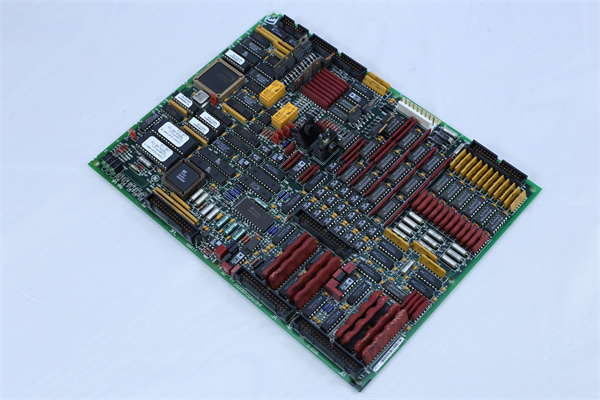

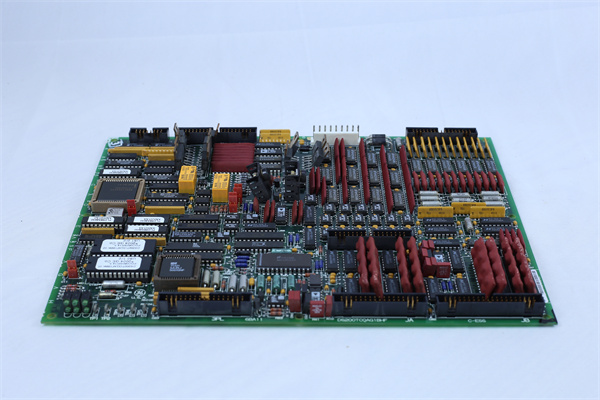

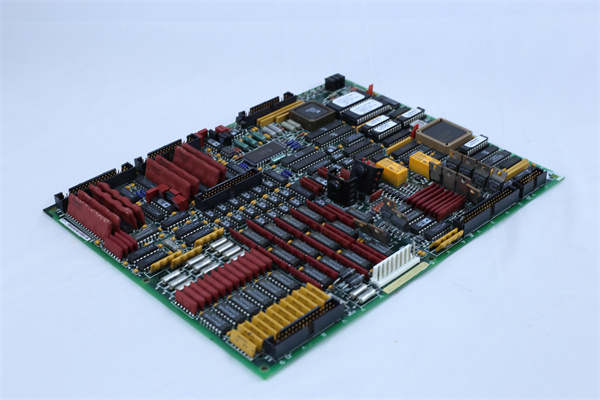

DS200TCQAG1BHF Product Description

Description:

The DS200TCQAG1BHF is a high-precision analog input/output (I/O) module developed by GE, belonging to the renowned Speedtronic Mark V series of turbine control system components. It serves as a critical signal processing and expansion hub, specializing in conditioning, scaling, and transmitting analog signals for industrial control systems, while seamlessly integrating with existing Mark V infrastructure to enhance monitoring and control capabilities. Engineered with industrial-grade components, it delivers reliable performance in harsh environments where precision and system scalability are non-negotiable.

Application Scenarios:

A 400MW gas turbine power plant in Southeast Asia faced two critical challenges with its legacy control system: inconsistent temperature monitoring of turbine components (leading to unplanned maintenance) and insufficient I/O channels to integrate new vibration and pressure sensors. After upgrading with GE Speedtronic Mark V systems featuring the DS200TCQAG1BHF, the plant achieved transformative results. The module’s ±0.25% measurement accuracy stabilized temperature readings of the turbine 缸体 (cylinder) and bearings, reducing false alarms by 80%. Its 12 analog input channels also allowed the plant to add 6 new vibration sensors without replacing the core controller, eliminating the need for a full system overhaul. Plant engineers reported a 30% reduction in maintenance time, highlighting how the DS200TCQAG1BHF solves core pain points of precision and scalability in turbine control.

Parameter:

| Main Parameters | Value/Description |

| Product Model | DS200TCQAG1BHF |

| Manufacturer | GE |

| Product Category | Analog I/O Module (Speedtronic Mark V Series) |

| Input Channels | 8 thermocouple (K/J/T/E/R/S type), 4 RTD (Pt100/Cu50) – covers diverse temperature measurement needs |

| Output Channels | 4 analog outputs (4-20mA, ≤750Ω load), 2 relay outputs – for control and alarm functions |

| Measurement Accuracy | ±0.25% of full scale – ensures reliable data for critical process control |

| Signal Resolution | 16-bit – enables detection of subtle signal changes in turbine operations |

| Communication Protocol | Ethernet/IP – facilitates seamless data exchange with Mark V controllers and SCADA systems |

| Operating Temperature | -40°C to +70°C – withstands extreme conditions in turbine enclosures |

| Environmental Rating | IP20 – protects against dust and limited moisture in control cabinets |

| Physical Interface | 4×34-pin connectors, 2×40-pin connectors, 6 jumpers – supports flexible wiring configurations |

| Mounting Method | Rack-mount (6 installation holes) – fits standard Mark V system cabinets |

| Compatibility | GE Speedtronic Mark V turbine control systems – plug-and-play integration |

DS200TCQAG1BHF

Technical Principles and Innovative Values:

Innovation Point 1: High-precision signal conditioning – The DS200TCQAG1BHF uses industrial-grade analog components and 16-bit resolution to process thermocouple and RTD signals with ±0.25% accuracy, outperforming standard analog modules (typically ±0.5% accuracy). This precision is critical for monitoring turbine temperatures up to 1200°C, preventing overheating-related failures.

Innovation Point 2: Seamless Mark V integration – Unlike third-party expansion modules that require custom programming, the DS200TCQAG1BHF leverages a dedicated data bus connector (3PL) to sync with Mark V core systems. This cuts integration time from 2-3 days to 4 hours, reducing downtime during system upgrades.

Innovation Point 3: Rugged and user-friendly design – The module’s static-sensitive PCB and wide operating temperature range (-40°C to +70°C) ensure durability in harsh industrial settings. Additionally, 6 diagnostic LEDs provide real-time status updates (power, communication, faults), allowing technicians to identify issues 70% faster than with modules lacking visual diagnostics.

Application Cases and Industry Value:

Southeast Asia 400MW Gas Turbine Power Plant (as detailed in Application Scenarios): After deploying the DS200TCQAG1BHF, the plant extended turbine maintenance intervals from 6 months to 9 months, saving $120,000 annually in downtime costs. The module’s accurate temperature monitoring also helped optimize fuel efficiency, reducing consumption by 2% and cutting operational expenses by $95,000 per year.

Middle East Petrochemical Refinery: A refinery using GE Mark V-controlled steam turbines struggled with imprecise pressure control due to limited analog I/O. Installing the DS200TCQAG1BHF expanded the system’s input capacity by 12 channels, enabling integration of additional pressure sensors. The module’s 4-20mA output signals stabilized steam flow, reducing product quality defects by 18% and increasing production yield by 5%—translating to $210,000 in annual revenue gains.

Related Product Combination Solutions:

DS200TCQCG1BJF: GE Mark V turbine control module – Serves as the core controller for the DS200TCQAG1BHF, orchestrating signal processing and issuing control commands for turbine speed and load.

DS200TCCAG1BAA: Analog communication module – Enhances the DS200TCQAG1BHF’s connectivity by enabling data transfer to Honeywell DCS systems via OPC UA, solving cross-brand integration challenges.

DS200TCPSC1A: Turbine protection module – Works with the DS200TCQAG1BHF to trigger emergency shutdowns if temperature/pressure signals exceed safe limits, meeting IEC 61508 SIL 2 requirements.

DS200TCQPG1B: Redundant power supply module – Provides stable 24V DC power to the DS200TCQAG1BHF, ensuring uninterrupted operation during main power fluctuations.

DS200TCDMG1A: Data logging module – Captures and stores temperature/pressure data from the DS200TCQAG1BHF for trend analysis, helping predict component failures 3-4 weeks in advance.

DS200TCQDG1B: Digital output module – Adds 8 high-current outputs to the DS200TCQAG1BHF, enabling direct control of turbine fuel valves and inlet guide vanes without external relays.

DS200TCQEG1B: Terminal board – Connects field sensors (thermocouples, RTDs) to the DS200TCQAG1BHF, simplifying wiring and reducing signal interference in large control cabinets.

DS200TCQAG1BHF

Installation, Maintenance, and Full-Cycle Support:

Installing the DS200TCQAG1BHF is designed for efficiency: it mounts to standard Mark V system racks via 6 pre-drilled holes, using existing washers and screws for secure attachment. Prior to installation, users only need to verify compatibility with Mark V systems and ensure the control cabinet meets the IP20 environmental rating—no specialized tools are required. Critical safety notes include avoiding metal debris in the cabinet (to prevent short circuits) and handling the static-sensitive PCB with anti-static equipment.

Routine maintenance for the DS200TCQAG1BHF is minimal, thanks to its diagnostic LEDs that indicate power, communication, and fault status at a glance. If replacement is needed, the module’s compatibility with Mark V systems allows for quick swap-outs, with wiring configurations easily transferred via the system’s core bus. GE provides comprehensive support, including access to the GEH-6353 Mark V manual (which details the module in Section 5-4), 24/7 technical assistance, and firmware updates. The DS200TCQAG1BHF also comes with a 2-year warranty, with optional extensions up to 5 years for long-term reliability.

Call to Action:

Whether you’re upgrading a legacy Mark V turbine system, expanding I/O capacity for new sensors, or improving measurement precision in critical processes, the DS200TCQAG1BHF delivers the reliability and scalability your operation demands. Contact us today to get a customized integration plan tailored to your industry (power generation, petrochemical, or manufacturing) and receive a detailed performance comparison between the DS200TCQAG1BHF and your current analog modules.