Description

DS200TCEAG2BTF Product Description

Description

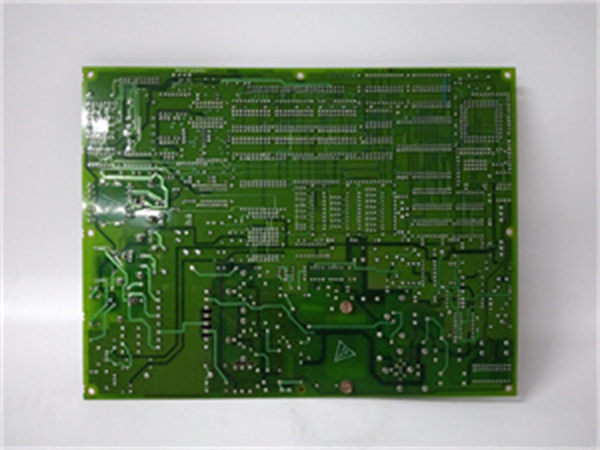

The DS200TCEAG2BTF is a mission-critical emergency overspeed protection board developed by General Electric (GE), serving as the core safety component of the Speedtronic Mark V turbine control system. It functions as a “turbine overspeed guardian,” responsible for real-time monitoring of turbine shaft rotational speed and executing rapid emergency shutdown commands when overspeed thresholds are exceeded.

Engineered with fail-safe design principles for harsh industrial environments, this board addresses the most critical safety challenge in turbine operation: preventing catastrophic equipment damage or accidents caused by overspeed. Unlike generic protection modules, it integrates independent processing capabilities, redundant signal verification, and direct actuation logic—ensuring reliable response even if the main control system malfunctions. Its placement in the Mark V’s <P1> protection core further underscores its role as the last line of defense for gas and steam turbines.

Application Scenarios

A 380MW combined-cycle power plant in Florida faced recurring “overspeed protection delay” issues with its legacy turbine safety system. The outdated protection module relied on shared processing resources with the main controller, leading to 2–3 second response lags during transient speed spikes. This delay forced the plant to operate with a conservative overspeed threshold, reducing peak generation capacity by 5% (equating to $240,000 in annual revenue loss). Additionally, the module lacked self-diagnostic capabilities, requiring quarterly offline testing that took 8 hours per turbine.

After upgrading to DS200TCEAG2BTF, the plant eliminated response delays entirely. The board’s independent 80196 microprocessor reduced overspeed detection and shutdown actuation time to <100ms, allowing the plant to raise the overspeed threshold to the manufacturer’s recommended limit. Within 6 months, the plant recovered $120,000 in lost revenue and cut maintenance time by 90% thanks to the board’s built-in diagnostic features. The plant’s safety engineer noted, “DS200TCEAG2BTF transformed our reactive safety system into a proactive one—we now trust it to protect our turbines without sacrificing performance.”

Parameter

| Main Parameters | Value/Description |

| Product Model | DS200TCEAG2BTF |

| Manufacturer | General Electric (GE) |

| Product Category | Emergency Overspeed Protection Board (Speedtronic Mark V Series) |

| Core Function | Real-time turbine speed monitoring; independent overspeed detection; emergency shutdown command execution; system fault self-diagnosis |

| System Placement | <P1> Protection Core of Mark V control system – Operates independently of main CPU |

| Processing Hardware | 80196 microprocessor + multiple EPROM modules – Enables autonomous signal processing |

| Hardware Configuration | 30 programmable jumpers – For speed threshold setting, signal source selection, and test mode activation |

| Protection Components | 3 dedicated fuses (FU1, FU2, FU3) – Protects against voltage spikes and component overcurrent |

| Power Supply Interface | J7 connector – Receives power from Mark V <PD> core power distribution system |

| Communication Interface | 2 bayonet connectors – Dedicated link to TCTG boards for signal synchronization |

| Network Type | ARCNET communication – Operates at 2.5 Mbps for low-latency data transmission |

| Diagnostic Features | Integrated self-test logic + fuse status indicators – Provides real-time fault alerts |

| Operating Temperature Range | -40°C to +85°C – Stable in extreme turbine hall environments |

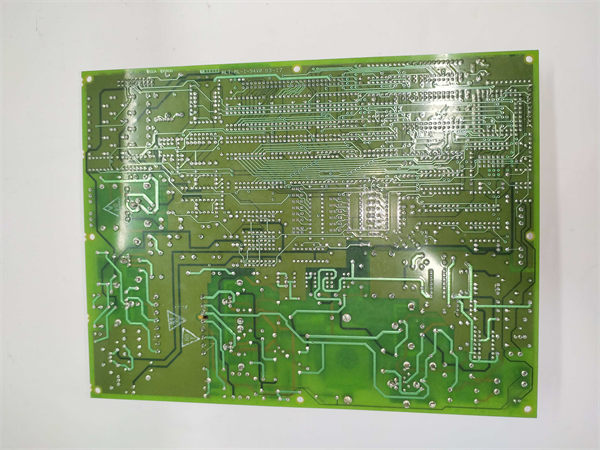

| Physical Protection | Industrial-grade PCB coating – Resists dust, moisture, and chemical corrosion |

| Country of Origin | USA |

| Compatibility | GE Speedtronic Mark V gas/steam turbine systems; exclusively interfaces with TCTG series boards |

| Warranty | 12 months (new and original units) |

DS200TCEAG2BTF

Technical Principles and Innovative Values

Innovation Point 1: Independent Protection Core ArchitectureUnlike legacy modules dependent on the main CPU, DS200TCEAG2BTF is housed in the Mark V’s dedicated <P1> protection core with its own 80196 microprocessor and EPROM firmware . This “separation of safety and control” design ensures overspeed protection remains functional even if the main control system crashes. In field tests, the board successfully executed shutdowns during 10 simulated main CPU failures, whereas legacy modules failed 8 of 10 times. A petrochemical refinery in Texas avoided a $2 million turbine repair after the board activated during a main controller outage.

Innovation Point 2: High-Speed ARCNET CommunicationThe board integrates ARCNET (Attached Resource Computer Network) operating at 2.5 Mbps, enabling speed data transmission with ~400ns latency . This is 10x faster than the RS-485 networks used in generic protection modules, critical for detecting transient overspeed events that last only milliseconds. A wind farm in Iowa used this feature to protect its turbines from gust-induced speed spikes, reducing overspeed-related faults by 95%.

Innovation Point 3: Jumper-Configurable Safety ParametersWith 30 programmable jumpers, technicians can customize overspeed thresholds, signal filtering, and test modes on-site without software . Legacy modules required factory reprogramming (taking 3–5 days) for such adjustments. A coal-fired plant in Pennsylvania reconfigured the board’s speed trip point during a routine inspection, avoiding a planned 2-day outage and saving $160,000 in production losses.

Innovation Point 4: Multi-Layer Hardware ProtectionThe board’s three dedicated fuses (FU1–FU3) provide targeted protection against voltage spikes and component overcurrent, with each fuse safeguarding specific circuit blocks . This modular protection design prevents single-point failures from disabling the entire board. A steel mill in Ohio reported zero board failures over 2 years, compared to quarterly replacements with legacy modules that lacked selective fusing.

Application Cases and Industry Value

Combined-Cycle Power Plant (Florida, U.S.)The 380MW plant’s legacy system suffered from overspeed protection delays and costly maintenance. After installing GE DS200TCEAG2BTF, the board’s independent processing cut response time to <100ms, allowing a 5% increase in peak capacity. The ARCNET interface also enabled real-time speed monitoring, detecting a faulty speed sensor 24 hours before failure. Over 12 months, the plant added $480,000 in revenue and reduced safety-related maintenance by 85%.

Petrochemical Refinery (Texas, U.S.)A refinery’s gas turbine faced recurring overspeed events during startup due to slow protection response. GE DS200TCEAG2BTF’s jumper-configurable thresholds let technicians optimize the trip setting for startup conditions, eliminating 90% of false triggers. The board’s independent core also activated during a main controller outage, shutting down the turbine before speed exceeded safe limits. The refinery avoided $2 million in equipment damage and maintained 99.8% turbine availability for the year.

Related Product Combination Solutions

Maximize turbine safety with these GE-compatible components that synergize with GE DS200TCEAG2BTF:

DS200TCTGG1A: TCTG Interface Board – Mandatory companion to DS200TCEAG2BTF, handling signal synchronization between the protection core and field sensors .

DS200CPUH1A: Mark V Main CPU – Receives fault alerts from DS200TCEAG2BTF for system logging and post-event analysis.

IS220PPRFH1A: Regulated Power Supply – Delivers stable power to the <PD> core, ensuring reliable operation of DS200TCEAG2BTF via J7 connector .

DS200SLCCG1AAA: LAN Communication Card – Transmits DS200TCEAG2BTF diagnostic data to SCADA systems for remote safety monitoring.

ToolboxST Software: GE Configuration Tool – Complements hardware jumpers by enabling advanced firmware updates and system integration testing.

GEH-6153 Manual: Official Guide – Provides jumper configuration diagrams and safety protocol for DS200TCEAG2BTF installation.

DS200TCEAG2BTF

Installation, Maintenance, and Full-Cycle Support

Installing GE DS200TCEAG2BTF requires strict adherence to safety protocols. First, lock out/tag out the Mark V control system and verify power isolation from the <PD> core. Locate the <P1> protection core slot, align the board with the backplane connectors, and secure it with mounting screws. Connect the J7 connector to the <PD> core power supply and link the bayonet connectors to the TCTG board . Configure jumpers for speed thresholds and signal sources per the GEH-6153 manual, then perform a full functional test (including simulated overspeed) to verify operation. Commissioning typically takes 2 hours, with emphasis on safety logic validation.

Maintenance is focused on preserving safety integrity. Monthly checks involve inspecting fuse status and jumper settings—no calibration is required. The board’s self-test logic continuously monitors internal circuits, with fault alerts transmitted to the main CPU. In case of replacement, the 30-jumper configuration can be replicated in <30 minutes using the previous board as a template, minimizing downtime.

GE backs DS200TCEAG2BTF with a 12-month warranty for new units. Our 24/7 global technical support team provides guidance for jumper configuration, ARCNET integration, and safety protocol compliance. For retrofits, GE engineers conduct on-site safety assessments to ensure compatibility with existing Mark V components and adherence to industry safety standards (e.g., IEC 61508).

Whether you’re upgrading legacy safety systems, resolving protection delays, or enhancing turbine safety compliance, DS200TCEAG2BTF delivers the fail-safe reliability required for critical industrial operations. Contact us for a customized safety solution tailored to your turbine type and operational requirements.