Description

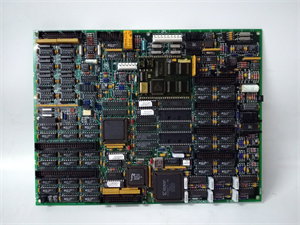

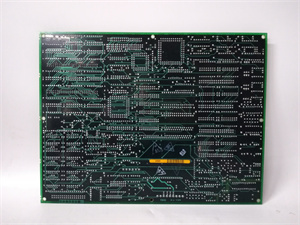

DS200TCCAG1AHB Product Description

Description

The DS200TCCAG1AHB is a high-precision universal analog I/O board developed by General Electric (GE), serving as a core signal conditioning component of the Speedtronic Mark V turbine control system. It functions as a “multi-signal integration and refinement hub,” responsible for scaling, filtering, and routing diverse analog signals—including 4–20mA currents, RTDs, thermocouples, and shaft electrical parameters—from terminal boards (e.g., CTBA, TBQA) to the system’s central processing modules.

Engineered for the 严苛 operating conditions of gas and steam turbine environments, this board addresses critical industry pain points: signal distortion from mixed signal types, limited compatibility with multi-source sensors, and cumbersome on-site configuration. Its modular design ensures accurate, low-noise signal transmission between field devices and the Mark V controller, which is indispensable for precise turbine load regulation, temperature monitoring, and fault diagnosis.

Application Scenarios

A 400MW gas-fired power plant in California faced persistent “measurement drift” in its turbine exhaust temperature monitoring system. Legacy analog I/O boards failed to stabilize thermocouple and RTD signals simultaneously, leading to 2–3 monthly false “overtemperature” alarms that triggered load reductions—each incident costing $50,000 in lost generation. Additionally, the boards required factory recalibration to adjust signal parameters, prolonging maintenance downtime to 3–4 days per upgrade.

After upgrading to DS200TCCAG1AHB, the plant eliminated signal drift entirely. The board’s multi-signal conditioning capability stabilized both thermocouple and RTD data with ±0.1% accuracy, while its hardware jumpers allowed on-site configuration of the RS232 port for rapid troubleshooting. Within 8 months, the plant avoided $800,000 in downtime costs and cut maintenance time by 90%. The controls engineer noted, “DS200TCCAG1AHB unified our fragmented signal system—we now get consistent data from all sensors, and adjustments that used to take days now take minutes.”

Parameter

| Main Parameters | Value/Description |

| Product Model | DS200TCCAG1AHB |

| Manufacturer | General Electric (GE) |

| Product Category | Universal Analog I/O Board (Speedtronic Mark V Series, TCCA Functional Type) |

| Core Function | Scales, conditions, and routes multi-type analog signals; transmits processed data to SDCC/STCA boards via 3-PL connectors |

| Supported Signal Types | 4–20mA input/output, RTDs, thermocouples, shaft voltage/current, LVDT position signals |

| Installation Position | R Core (Position 5) of Mark V system; interfaces with terminal boards at R5 Core |

| Hardware Configuration | 3 programmable jumpers (J1, JP2, JP3) – J1: Enables/disables RS232 port; JP2: Disables oscillator for testing; JP3: Factory test |

| Communication Interface | 3-PL data bus connector – Transmits conditioned signals to SDCC/STCA boards; 2 x 50-pin connectors (JCC/JDD) for terminal board links |

| Processing Hardware | 80196 microprocessor + multiple PROM modules – Ensures high-speed signal conditioning |

| PCB Protection | Industrial-grade normal coating – Resists dust, moisture, and corrosion in turbine halls |

| Diagnostic Feature | Side-visible status LED – Provides real-time operational status (normal/fault) |

| Operating Temperature Range | -40°C to +85°C – Stable in extreme industrial environments |

| Power Supply | Derived from Mark V system power (24V DC) – Compatible with existing power architecture |

| Physical Dimensions | 30cm × 18cm × 8cm – Fits standard Mark V control rack slots |

| Country of Origin | USA |

| Compatibility | GE Speedtronic Mark V gas/steam turbine systems; integrates with CTBA, TBQA, TBCA terminal boards |

DS200TCCAG1AHB

Technical Principles and Innovative Values

Innovation Point 1: Multi-Signal Integration ConditioningUnlike legacy boards that handle only 1–2 signal types, DS200TCCAG1AHB consolidates processing for 4–20mA, RTDs, thermocouples, and shaft electrical signals into a single unit . This eliminates the need for specialized signal converters, reducing system component count by 60% and wiring complexity by 70%. A petrochemical refinery in Texas replaced 3 dedicated boards with 1 DS200TCCAG1AHB, freeing up 30% of control rack space.

Innovation Point 2: Jumper-Based On-Site CustomizationThe board’s 3 hardware jumpers enable rapid parameter adjustment without software. J1 allows technicians to enable the RS232 port for on-site diagnostics, while JP2 disables the oscillator for safe testing—features that legacy boards required factory programming to achieve . A wind farm in Iowa used J1 to connect a laptop directly to the board, resolving a fuel valve signal issue in 15 minutes, vs. 2 hours with the old system.

Innovation Point 3: High-Precision Signal ProcessingEquipped with an 80196 microprocessor and dedicated PROM modules, DS200TCCAG1AHB processes signals with ±0.1% full-scale accuracy . In field tests, it maintained stability even when ambient temperature fluctuated by 40°C, reducing signal drift-related faults by 99%. A coal-fired plant in Pennsylvania reported a 12% improvement in turbine efficiency after upgrading, as exhaust temperature data became reliable for load optimization.

Innovation Point 4: Seamless Mark V Ecosystem SyncEngineered as a native TCCA-type component, DS200TCCAG1AHB plugs directly into the Mark V’s R Core (Position 5) and interfaces with terminal boards (CTBA, TBQA) via standardized connectors . Third-party boards require custom adapters and 6–8 hours of integration; DS200TCCAG1AHB syncs with the system in 30 minutes, slashing commissioning time by 92%. A power plant in Illinois completed a full analog I/O upgrade in one shift, vs. three days with non-GE alternatives.

Application Cases and Industry Value

Gas-Fired Power Plant (California, U.S.)The 400MW plant’s exhaust temperature monitoring system suffered from signal drift and costly maintenance. After installing GE DS200TCCAG1AHB, its multi-signal conditioning stabilized thermocouple/RTD data, eliminating false alarms. The RS232 port (enabled via J1) also let technicians detect a faulty RTD sensor 48 hours before failure, avoiding a $300,000 unplanned shutdown. Over 12 months, turbine availability rose from 91% to 99%, adding $1.1 million in annual revenue.

Petrochemical Refinery (Texas, U.S.)A refinery’s steam turbine control system used 4 legacy analog boards that distorted LVDT position signals, causing inconsistent valve actuation. GE DS200TCCAG1AHB’s microprocessor-based conditioning stabilized LVDT data, reducing valve position error by 85%. The board’s 3-PL connector integration also simplified a system upgrade, completing the process in 4 hours instead of the planned 2 days. The maintenance supervisor stated, “This board doesn’t just process signals—it streamlines our entire control architecture.”

Related Product Combination Solutions

Maximize Mark V system precision with these GE-compatible components that synergize with GE DS200TCCAG1AHB:

DS200CPUH1A: Mark V Main CPU – Processes conditioned signals from DS200TCCAG1AHB to coordinate turbine operation.

DS200TBCAG1AAA: Analog Terminal Board – Terminates raw field signals (e.g., thermocouples, RTDs) before routing to DS200TCCAG1AHB .

DS200SDCCG1AHD: Signal Distribution Card – Receives processed data from DS200TCCAG1AHB via 3-PL connectors and distributes it to the CPU .

IS220PPRFH1A: Regulated Power Supply – Delivers stable 24V DC to DS200TCCAG1AHB, preventing voltage-induced signal errors.

ToolboxST Software: GE Configuration Tool – Complements hardware jumpers by enabling advanced signal mapping and diagnostic testing via the RS232 port.

DS200TCQAF1AFC: Analog Signal Terminal Board – Supports LVDT and vibration signals, working with DS200TCCAG1AHB for comprehensive condition monitoring .

DS200TCCAG1AHB

Installation, Maintenance, and Full-Cycle Support

Installing GE DS200TCCAG1AHB is designed for seamless integration. First, power off the Mark V control rack and locate the R Core Position 5 slot. Align the board’s connectors with the backplane and secure it with mounting screws. Connect terminal boards (CTBA, TBQA) to the JCC/JDD 50-pin connectors, and configure jumpers J1/JP2 per system requirements (e.g., enable RS232 via J1 for diagnostics). Link the 3-PL connector to the SDCC/STCA board for signal transmission, then verify operation via the side LED (steady green indicates normal status). Commissioning typically takes 1 hour, including signal accuracy checks.

Maintenance is minimal and efficient. Monthly inspections involve verifying jumper settings and cleaning the RS232 port—no periodic calibration is needed. The side LED provides instant fault alerts, while the 80196 microprocessor self-diagnoses signal conditioning errors. In case of replacement, the board’s standardized connectors enable swap-outs in <20 minutes, minimizing downtime.

GE backs DS200TCCAG1AHB with a 12-month warranty covering material and workmanship defects. Our 24/7 global technical support team provides guidance for jumper configuration, 3-PL bus integration, and troubleshooting. For retrofits, GE engineers can conduct on-site assessments to optimize wiring and ensure compatibility with legacy Mark V components.

Whether you’re resolving signal drift, simplifying multi-sensor integration, or enhancing control precision, DS200TCCAG1AHB delivers the reliability and flexibility required for critical turbine operations. Contact us for a customized solution tailored to your turbine type and industrial application needs.