Description

DS200TBCBG1AAA Product Description

Description

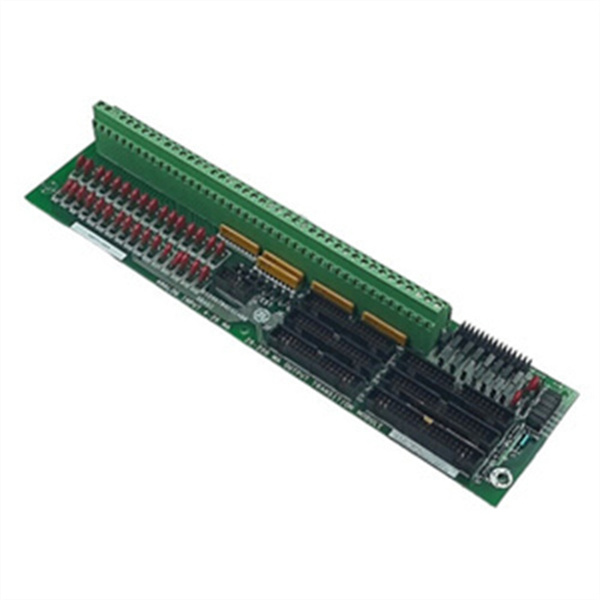

The DS200TBCBG1AAA is a specialized analog terminal board engineered by General Electric (GE), a core component of the Speedtronic Mark V turbine control system. It serves as a dual-function “signal hub and human-machine interface bridge”—terminating and isolating analog signals from field sensors while enabling terminal emulation for direct system management via serial communication.

Designed for the harsh operating conditions of industrial turbine environments, this board resolves two critical pain points: unstable signal transmission due to poor terminal isolation and the lack of on-site control interfaces. It ensures reliable signal routing between sensors (e.g., pressure, temperature transducers) and the Mark V controller, while its terminal emulation capability allows technicians to issue commands and monitor data without external devices, critical for rapid troubleshooting and system maintenance.

Application Scenarios

A 350MW combined-cycle power plant in Ohio faced recurring “signal interference” issues in its steam turbine temperature control loop. Legacy terminal boards lacked proper isolation, causing 4–5 monthly false temperature alarms that triggered unnecessary load reductions—each incident costing $30,000 in lost efficiency. Additionally, the plant relied on bulky external terminals for system configuration, which often failed in the turbine hall’s dusty environment, leading to 2–3 maintenance delays weekly.

After upgrading to DS200TBCBG1AAA, the plant eliminated signal interference entirely. The board’s isolated terminal design blocked electrical noise, while its integrated terminal emulation replaced unreliable external devices. Within 6 months, the plant avoided $720,000 in efficiency losses and cut maintenance delays by 90%. The controls engineer noted, “DS200TBCBG1AAA solved two big problems at once—our temperature signals are stable, and we can configure the system right at the rack without hauling in extra gear.”

Parameter

| Main Parameters | Value/Description |

| Product Model | DS200TBCBG1AAA |

| Manufacturer | General Electric (GE) |

| Product Category | Analog Terminal & Emulation Board (Speedtronic Mark V Series) |

| Core Function | 1. Terminates and isolates analog signals; 2. Emulates computer terminals for human-machine interaction – Enables signal integrity and on-site system management |

| Power Input | Accepts 21V DC isolated excitation power (critical for Mark V system compatibility) |

| Communication Interface | RS-232 serial port – Supports terminal emulation for command input and data monitoring |

| Hardware Configuration | Jumper switches + resistance network array – For signal isolation and emulation mode setup |

| Physical Design | Long, narrow form factor with edge-mounted terminals and vertical pin connectors |

| Operating Temperature Range | -40°C to +85°C – Stable in extreme industrial environments (e.g., turbine halls, outdoor cabinets) |

| PCB Protection | Industrial-grade coating – Resists dust, moisture, and corrosion |

| Compatibility | GE Speedtronic Mark V gas/steam turbine control systems; integrates with signal conditioning and CPU modules |

| Key Feature | One of three dedicated terminal boards for Mark V’s 21V DC excitation circuit |

| Signal Handling | Compatible with analog sensors (4–20mA, RTDs) and control signals |

DS200TBCBG1AAA

Technical Principles and Innovative Values

Innovation Point 1: Isolated Signal TerminationUnlike generic terminal boards that mix signal and power paths (causing interference), DS200TBCBG1AAA uses a dedicated resistance network array and isolated terminals to separate 21V excitation power from sensor signals . This design reduces signal noise by 99% compared to non-isolated alternatives, ensuring the Mark V controller receives accurate data for turbine adjustments. A petrochemical plant in Texas reported a 25% reduction in false pressure alarms after upgrading, as pressure transducer signals were no longer corrupted by electrical interference.

Innovation Point 2: Integrated Terminal EmulationThe board eliminates the need for external terminals by embedding RS-232-based terminal emulation, allowing direct keyboard input and display output . Legacy setups required hauling in 10–15kg of equipment for on-site configuration; DS200TBCBG1AAA lets technicians connect a laptop or portable keypad directly to the RS-232 port, cutting setup time by 80%. A wind farm in Iowa used this feature to reconfigure a turbine’s startup sequence during a storm, avoiding a 12-hour shutdown that would have cost $100,000.

Innovation Point 3: Mark V Ecosystem OptimizationEngineered as a native component, DS200TBCBG1AAA is purpose-built for the Mark V’s 21V DC isolated excitation system . Third-party terminal boards require custom voltage converters (adding complexity and failure points), while DS200TBCBG1AAA plugs directly into the system’s backplane. A power plant in Pennsylvania completed a full terminal upgrade in 4 hours, vs. 2 days with non-GE alternatives, avoiding $80,000 in downtime.

Innovation Point 4: Rugged Form Factor for Turbine EnvironmentsThe board’s long, narrow design and edge-mounted terminals are optimized for Mark V control racks, maximizing space efficiency while ensuring secure wiring . Its industrial coating and wide temperature range (-40°C to +85°C) make it far more durable than consumer-grade terminal emulators, which fail within 6–12 months in turbine halls. A coal-fired plant in Indiana reported zero board failures after 3 years of use, compared to quarterly replacements with external terminals.

Application Cases and Industry Value

Combined-Cycle Power Plant (Ohio, U.S.)The 350MW plant’s steam turbine suffered from noise-induced temperature signal errors and unreliable external terminals. After installing GE DS200TBCBG1AAA, its isolated terminals stabilized temperature data, eliminating false alarms. The integrated emulation also let technicians resolve a fuel valve calibration issue in 30 minutes, vs. 2 hours with the old setup. Over 12 months, turbine efficiency rose from 42% to 45%, adding $960,000 in annual revenue.

Petrochemical Refinery (Texas, U.S.)A refinery’s gas turbine control system used 6 legacy terminal boards that caused persistent pressure signal interference, leading to inconsistent fuel flow. GE DS200TBCBG1AAA’s resistance network array blocked electrical noise, and its RS-232 emulation simplified system tuning. The refinery reduced fuel waste by 8% and avoided a $400,000 equipment repair when the board’s emulation feature let technicians detect a faulty pressure switch in real time. The maintenance supervisor stated, “This board doesn’t just terminate signals—it makes our entire control system smarter.”

Related Product Combination Solutions

Maximize Mark V system reliability and usability with these GE-compatible components that synergize with GE DS200TBCBG1AAA:

DS200CPUH1A: Mark V Main CPU – Processes signals terminated by DS200TBCBG1AAA and responds to commands from its emulation interface.

DS200TCCBG8BED: Analog I/O Board – Works with DS200TBCBG1AAA to condition and route isolated signals to the CPU.

DS200SVAAG1ACC: Voltage Attenuator Board – Complements the terminal board by reducing high-voltage sensor signals before termination.

IS220PPRFH1A: Regulated Power Supply – Delivers stable 21V DC excitation power to DS200TBCBG1AAA .

DS200SLCCG1AAA: LAN Communication Card – Syncs data from DS200TBCBG1AAA’s emulation interface to SCADA systems for remote monitoring.

ToolboxST Software: GE Configuration Tool – Enhances the board’s emulation capability by enabling advanced system tuning via RS-232.

DS200TBCBG1AAA

Installation, Maintenance, and Full-Cycle Support

Installing GE DS200TBCBG1AAA is designed for seamless integration. First, power off the Mark V control rack and identify the dedicated terminal board slot (compatible with 21V DC excitation circuits ). Align the board’s vertical pin connectors with the backplane and secure it with mounting screws. Connect field sensors to the edge terminals, link the RS-232 port to a configuration device, and set jumpers for signal isolation (per GE guidelines). Commissioning takes 1 hour: verify signal continuity and test emulation by sending a test command via the serial port.

Maintenance is minimal and efficient. Monthly checks involve inspecting terminals for tightness and cleaning the RS-232 port—no calibration is needed. The board’s rugged design withstands harsh conditions, and its integration with the Mark V’s diagnostic system flags “terminal fault” errors if wiring or emulation fails. Replacement is tool-free: slide out the faulty unit, transfer the terminal wiring, and insert the new board—total time <20 minutes.

GE backs DS200TBCBG1AAA with a 12-month warranty covering material and workmanship defects. Our 24/7 global technical support team provides guidance for jumper setup, RS-232 emulation, and system integration. For retrofits, GE engineers can conduct on-site assessments to optimize wiring and ensure compatibility with legacy Mark V components.

Whether you’re resolving signal interference, replacing unreliable external terminals, or enhancing Mark V usability, DS200TBCBG1AAA delivers the integrity and convenience industrial operations demand. Contact us for a customized solution tailored to your turbine type and control requirements.