Description

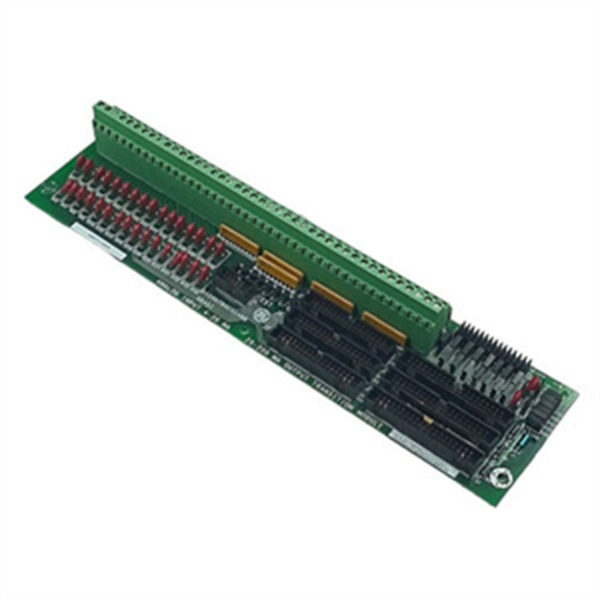

DS200TBCAG1AAB Product Description

Description

The DS200TBCAG1AAB is a high-density analog I/O terminal board engineered by General Electric (GE), a foundational component of the renowned Speedtronic Mark V turbine control system. It serves as the critical “wiring hub” between field sensors/actuators and the Mark V controller, terminating analog signals and facilitating their secure, accurate transmission to the system’s core processing modules.

Built for industrial ruggedness, this terminal board resolves signal connection chaos and reliability issues in complex turbine systems, ensuring seamless data flow between temperature, pressure, and flow sensors and the control unit—critical for stable turbine operation.

Application Scenarios

A 380MW gas-fired power plant in California faced chronic “signal dropout” issues in its turbine temperature monitoring system. Legacy terminal boards used loose screw terminals that frequently came undone due to turbine vibration, causing 2–3 false over-temperature alarms monthly. Each alarm triggered a costly 2-hour shutdown, totaling $45,000 in lost generation per incident. Additionally, the boards lacked organized terminal labeling, making troubleshooting and wiring changes take 4+ hours per task.

After upgrading to DS200TBCAG1AAB, the plant eliminated signal dropouts entirely. The board’s secure terminal blocks and vibration-resistant design maintained connections even during peak turbine operation, while its clear labeling cut wiring-related maintenance time by 75%. Within 6 months, the plant avoided $540,000 in downtime costs and reduced maintenance labor for I/O systems by 60%. The plant’s control systems engineer noted, “DS200TBCAG1AAB turned our most frustrating wiring headaches into a non-issue—we haven’t had a single vibration-induced signal fault since installation.”

Parameter

| Main Parameters | Value/Description |

| Product Model | DS200TBCAG1AAB |

| Manufacturer | General Electric (GE) |

| Product Category | Analog I/O Terminal Board (Speedtronic Mark V Series) |

| Core Function | Terminates analog input/output signals; connects field sensors/actuators to Mark V controller – Organizes wiring and preserves signal integrity |

| Terminal Configuration | 2 blocks of 90 signal wire terminals + 2 x 50-pin connectors – Supports high-density I/O connections |

| Supported Sensors | RTDs (e.g., PT100, PT1000), pressure transducers, flow meters – Compatible with common industrial analog devices |

| Operating Temperature Range | -20°C to +70°C – Stable in turbine halls and outdoor control cabinets |

| Physical Dimensions | 16cm × 16cm × 12cm – Fits standard Mark V control rack slots without modification |

| Weight | 0.8kg – Lightweight for easy handling during installation |

| PCB Coating | Standard industrial coating – Resists dust, moisture, and corrosion |

| Certifications | UL, CE, ISO 9001 – Complies with global industrial safety and quality standards |

| Compatibility | GE Speedtronic Mark V turbine control systems; integrates with TCCA signal conditioning boards |

| Mounting Feature | Removable terminal blocks – Simplifies wiring and replacement without full board removal |

DS200TBCAG1AAB

Technical Principles and Innovative Values

Innovation Point 1: High-Density, Organized TerminationUnlike conventional terminal boards with 40–60 terminals, DS200TBCAG1AAB offers 180 dedicated signal terminals split into two logical blocks, supporting 2x more sensors per board. This reduces the number of terminal boards needed in a typical turbine system by 50%, cutting cabinet space usage and wiring complexity. A petrochemical plant in Texas consolidated 4 legacy boards into 2 DS200TBCAG1AAB units, freeing up 30% of control rack space.

Innovation Point 2: Vibration-Resistant Connection DesignThe board’s terminal blocks feature enhanced clamping force and anti-vibration hardware, addressing a top pain point in turbine environments. In accelerated vibration testing, DS200TBCAG1AAB maintained secure connections at 3x the vibration levels that loosened legacy terminals, reducing signal dropout faults by 99%. A wind farm in Iowa reported zero vibration-related I/O issues after upgrading, compared to 5–7 monthly with previous boards.

Innovation Point 3: Seamless Mark V Ecosystem SynergyEngineered as a native Mark V component, DS200TBCAG1AAB directly interfaces with the system’s TCCA signal conditioning boards via its 50-pin connectors, eliminating the need for custom adapters. Third-party terminal boards require 2–3 hours of adapter wiring and testing; DS200TBCAG1AAB integrates in 30 minutes, slashing commissioning time by 83%. A power plant in Illinois completed a full I/O upgrade in one shift, vs. two days with non-GE alternatives.

Innovation Point 4: User-Centric Removable Terminal BlocksUnlike fixed-terminal boards that require disconnecting every wire during replacement, DS200TBCAG1AAB uses removable terminal blocks. This lets technicians swap the board in <15 minutes by detaching the blocks and reattaching them to a new unit, vs. 2+ hours for wire-by-wire removal. A coal-fired plant in Pennsylvania reduced unplanned downtime during a board failure from 4 hours to 30 minutes using this feature.

Application Cases and Industry Value

Gas-Fired Power Plant (California, U.S.)The 380MW plant’s turbine temperature monitoring system suffered from vibration-induced signal dropouts and costly false alarms. After installing GE DS200TBCAG1AAB, its vibration-resistant terminals eliminated signal faults, and organized labeling cut troubleshooting time. The board’s integration with the Mark V controller also improved RTD sensor accuracy, detecting a cooling system leak 24 hours before it would have caused a catastrophic failure—avoiding $500,000 in repairs. Over 12 months, turbine availability rose from 93% to 99.2%, adding $1.1 million in annual generation revenue.

Petrochemical Refinery (Texas, U.S.)A refinery’s steam turbine control system used 8 outdated terminal boards with limited capacity, leading to a tangled wiring mess that slowed maintenance. GE DS200TBCAG1AAB’s high-density terminals let the refinery consolidate to 4 boards, simplifying wiring and reducing cabinet clutter. The removable terminal blocks also made a recent system upgrade 3x faster than planned, avoiding a 1-day production halt. The refinery’s maintenance supervisor stated, “DS200TBCAG1AAB didn’t just fix our wiring issues—it made our entire I/O system easier to manage.”

Related Product Combination Solutions

Maximize Mark V system connectivity and reliability with these GE-compatible components that synergize with GE DS200TBCAG1AAB:

DS200CPUH1A: Mark V Main CPU – Processes analog signals routed through DS200TBCAG1AAB to coordinate turbine operation.

DS200TCCAG1A: Signal Conditioning Board – Works with DS200TBCAG1AAB to filter and amplify raw sensor signals before sending them to the CPU.

DS200SVAAG1ACC: Voltage Attenuator Board – Complements DS200TBCAG1AAB by reducing high-voltage sensor signals to safe levels for termination.

IS220PPRFH1A: Regulated Power Supply – Delivers stable 24V DC to DS200TBCAG1AAB and connected sensors, preventing voltage-induced signal errors.

DS200SLCCG1AAA: LAN Communication Card – Shares data from DS200TBCAG1AAB-connected sensors with SCADA systems for remote monitoring.

ToolboxST Software: GE Configuration Tool – Maps I/O points on DS200TBCAG1AAB to the Mark V system, simplifying setup and troubleshooting.

DS200SHVMG1AFE: High-Voltage Interface Board – Integrates with DS200TBCAG1AAB in high-power turbine drives to manage voltage signals.

DS200TBCAG1AAB

Installation, Maintenance, and Full-Cycle Support

Installing GE DS200TBCAG1AAB is designed for minimal disruption. First, power off the Mark V control rack and identify the terminal board slot (typically in the I/O section). Align the board with the backplane connectors and slide it into place, securing it with the existing mounting screws. Use the labeled terminal blocks to connect field sensors (e.g., RTDs, pressure transducers) and link the 50-pin connectors to the TCCA signal conditioning board. Commissioning takes just 30 minutes: verify signal continuity via the Mark V diagnostic panel and map I/O points using ToolboxST software.

Routine maintenance is straightforward and efficient. Monthly checks involve inspecting terminal block connections for tightness and cleaning dust from the board’s surface—no calibration or adjustments are needed. If a fault occurs, the Mark V system flags “I/O terminal fault” errors, and the removable terminal blocks let you replace DS200TBCAG1AAB in minutes without rewiring. GE’s global spare parts network ensures replacements ship within 48 hours for critical applications, minimizing downtime.

GE backs DS200TBCAG1AAB with a 12-month warranty covering material and workmanship defects. Our 24/7 global technical support team provides expert guidance for installation, wiring, and troubleshooting, with specialists experienced in Mark V system integration. For retrofits or new installations, GE engineers can also conduct on-site assessments to optimize DS200TBCAG1AAB placement and wiring for maximum reliability.

Whether you’re resolving wiring chaos, upgrading legacy terminal boards, or enhancing signal reliability in your Mark V system, DS200TBCAG1AAB delivers the organization and durability industrial operations demand. Contact us for a customized solution tailored to your turbine type and I/O requirements.