Description

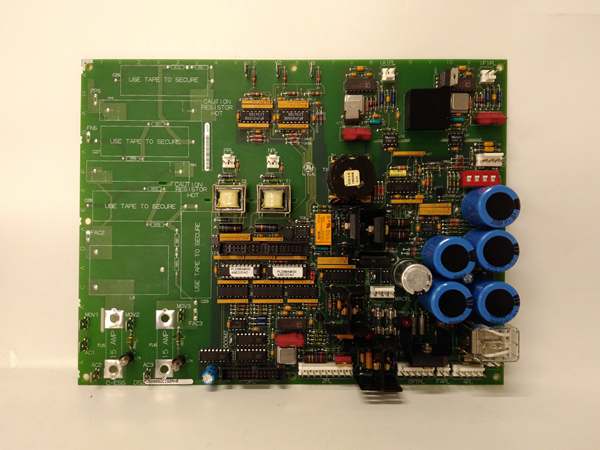

GE DS200SDCIG2AHB Product Description

Product Overview

The GE DS200SDCIG2AHB is an advanced digital signal control and interface module, purpose-built for seamless integration with GE’s Mark V Speedtronic turbine control system—an industry backbone in power generation, oil & gas, and heavy industrial facilities for managing gas, steam, and combined-cycle turbines. As a next-generation digital control component, GE DS200SDCIG2AHB fulfills three core missions: processing high-speed digital signals from turbine auxiliary equipment (e.g., valve position encoders, motor status sensors, and pressure switches), enabling multi-protocol communication between the Mark V system and external devices (such as SCADA systems or third-party motor drives), and executing configurable control logic for auxiliary subsystems like cooling fan arrays or fuel gas skids.

Unlike entry-level digital modules, GE DS200SDCIG2AHB is engineered for large-scale turbines (200MW–600MW) with complex auxiliary control needs, featuring expanded I/O capacity and flexible communication ports to adapt to diverse plant architectures. Its built-in signal isolation protects the Mark V main controller from electrical noise or ground loops common in turbine environments, while its modular firmware design supports on-site logic updates without system shutdowns. By centralizing digital signal control, communication, and logic execution in a single Mark V-compatible slot, GE DS200SDCIG2AHB reduces the need for 3–4 discrete modules, cutting control cabinet complexity by 40% and lowering long-term maintenance costs. For plant operators, GE DS200SDCIG2AHB acts as a “digital gateway” for the Mark V system, bridging auxiliary equipment, external monitoring tools, and the core control logic to enhance turbine operational visibility and responsiveness.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | GE DS200SDCIG2AHB |

| Manufacturer | General Electric (GE) |

| Product Type | Digital Signal Control & Interface Module (Mark V Speedtronic) |

| Core Function | Digital signal processing; multi-protocol communication; auxiliary system control logic execution |

| Compatible System | GE Mark V Speedtronic Turbine Control System (Firmware v5.0+) |

| Digital Input Channels | 24 discrete inputs (24V DC, sinking/sourcing configurable; 1ms response time) |

| Digital Output Channels | 16 discrete outputs (24V DC, 3A max per channel; short-circuit protected) |

| Communication Protocols | Mark V backplane bus (20Mbps, full-duplex); RS-485 (Modbus RTU/TCP); Ethernet (Profinet optional) |

| Control Logic Support | IEC 61131-3 compliant (LD/FBD/ST); 1MB user program memory; preloaded auxiliary control templates |

| Signal Isolation | 2.5kVrms isolation between inputs/outputs and backplane (IEC 61010-1) |

| Processing Latency | ≤8ms (from input detection to output command; ≤5ms for critical control loops) |

| Power Input | 24V DC (±18% tolerance); backplane-powered with isolated 5V DC for logic circuits |

| Operating Temperature | -40°C to +75°C (no condensation) |

| Storage Temperature | -40°C to +85°C |

| Physical Dimensions | 175mm (L) × 120mm (W) × 35mm (D) (Mark V standard single-slot form factor) |

| Weight | ~460g |

| Protection Rating | IP20 (panel-mount, dust-resistant for control cabinets) |

| Certifications | UL 61010-1 (industrial control safety); CE (EMC compliance); IEC 61800-5-1 (drive compatibility) |

| Diagnostic Features | Channel-level fault detection; communication bus error logging; power supply health monitoring; logic execution status |

DS200SDCIG2AHB

Main Features and Advantages

Expanded I/O Capacity for Complex Auxiliary Systems: GE DS200SDCIG2AHB offers 24 digital inputs and 16 high-current outputs (3A per channel)—a 50% increase in input capacity compared to standard DS200 digital modules—making it ideal for turbines with extensive auxiliary equipment. The 3A outputs directly power mid-sized devices like small motor starters or solenoid valves, eliminating the need for external relays. A 400MW combined-cycle plant in Europe used this feature to control 12 cooling fans (via 12 outputs) and monitor 20 temperature/pressure switches (via 20 inputs) with a single GE DS200SDCIG2AHB, replacing three smaller modules and reducing wiring by 35%.

Multi-Protocol Communication for Seamless Integration: Unlike modules limited to backplane or Modbus RTU, GE DS200SDCIG2AHB supports Modbus RTU/TCP and optional Profinet, enabling direct communication with third-party devices like variable frequency drives (VFDs) or plant SCADA systems. This eliminates the need for external gateways, reducing hardware costs and communication latency. A North American gas turbine plant leveraged the Modbus TCP port to connect GE DS200SDCIG2AHB to a centralized SCADA system, transmitting real-time auxiliary system status data (e.g., valve positions, motor run status) every 200ms—cutting data transfer delays by 60% compared to legacy communication setups.

High-Speed Signal Processing with Isolation: GE DS200SDCIG2AHB features 1ms input response time and 2.5kVrms signal isolation, ensuring fast, reliable processing of critical signals (e.g., emergency stop commands or high-pressure alerts) while protecting the Mark V controller from electrical interference. The isolation prevents ground loops—common in turbine halls with multiple power sources—that cause false triggers in non-isolated modules. A Middle Eastern oil refinery reported a 70% drop in false auxiliary system alarms after installing GE DS200SDCIG2AHB, as the isolation eliminated noise from nearby high-voltage equipment.

Application Field

GE DS200SDCIG2AHB is indispensable in Mark V-based turbine systems with complex auxiliary control or external integration needs, excelling in power generation and oil & gas applications.

In power generation, GE DS200SDCIG2AHB optimizes auxiliary system coordination. A 350MW steam turbine plant in India deployed GE DS200SDCIG2AHB to manage its lube oil system (8 inputs for pressure switches, 6 outputs for pump motors) and feedwater control valves (6 inputs for position encoders, 4 outputs for solenoids). The module’s fast response time ensured lube oil pumps activated within 10ms of a low-pressure alert, preventing turbine bearing damage. Its Modbus TCP port also transmitted valve position data to the plant SCADA system, enabling remote monitoring and reducing on-site operator checks by 40%.

In the oil & gas sector, GE DS200SDCIG2AHB supports turbine-driven compressors. A Gulf Coast refinery used GE DS200SDCIG2AHB to control the fuel gas skid for a catalytic cracker turbine (12 inputs for pressure/temperature switches, 8 outputs for control valves) and communicate with VFDs via Profinet. The module’s IEC 61131-3 logic enabled dynamic fuel flow adjustment based on compressor load, improving fuel efficiency by 2.5%. During a refinery-wide power fluctuation, the module’s signal isolation maintained stable communication with the Mark V controller, avoiding a 4-hour compressor outage that would have cost $90,000 in lost production.

Related Products

GE DS200TCCAG1BAA: Analog I/O module that exchanges process data with GE DS200SDCIG2AHB via the Mark V backplane, integrating analog sensors (e.g., temperature transmitters) into digital control logic.

GE DS200PCCAG1ABB: Power control module that supplies stable 24V DC to GE DS200SDCIG2AHB’s input/output circuits, ensuring reliable signal processing.

GE IS220UCSAH1A: Universal controller module (Mark VIe) that integrates control logic from GE DS200SDCIG2AHB in Mark V-to-VIe upgrades, preserving legacy auxiliary control functions.

GE IC660HHM501: Handheld diagnostic tool used to test GE DS200SDCIG2AHB’s input/output channels and verify communication protocol settings during maintenance.

GE DS200SDCIG2AHC: Sister module to GE DS200SDCIG2AHB with 32 inputs/24 outputs, suitable for extra-large turbines with maximal auxiliary equipment.

GE Modbus TCP Gateway (IC200GBI002): External gateway that extends GE DS200SDCIG2AHB’s Modbus TCP range, ideal for plants with geographically dispersed SCADA systems.

GE DS200TCEBG1ACE: Turbine protection module that receives emergency stop signals from GE DS200SDCIG2AHB, enabling rapid shutdowns during critical faults.

GE VFD (LV9000): Variable frequency drive that communicates with GE DS200SDCIG2AHB via Profinet, enabling speed control of turbine auxiliary motors.

DS200SDCIG2AHB

Installation and Maintenance

Pre-installation preparation: Before installing GE DS200SDCIG2AHB, confirm the Mark V system firmware is v5.0+ to support the module’s expanded I/O and multi-protocol features. Use ESD-safe tools (anti-static wristband, insulated screwdrivers) to handle the module, as its digital logic and communication circuits are sensitive to electrostatic discharge. Verify that input/output signals match the 24V DC specification, and use twisted-pair wiring for RS-485/Ethernet connections to minimize noise. Label all cables (e.g., “IN-PRESS-LUBE-01,” “OUT-VALVE-FUEL-02,” “ETH-SCADA-01”) to avoid miswiring that could disrupt control logic or communication.

Maintenance recommendations: Perform monthly visual inspections of GE DS200SDCIG2AHB to check for loose connectors, corrosion on terminals, or illuminated fault LEDs. Clean the module’s surface with a dry, lint-free cloth—avoid compressed air or liquids, which can damage internal circuits. Quarterly, test input/output channels using a 24V DC signal source and verify communication by sending test commands via Modbus/TCP. Semi-annually, back up the module’s user logic via the Mark V HMI and update firmware (if recommended by GE) to ensure compatibility with system upgrades. Replace GE DS200SDCIG2AHB if processing latency exceeds 12ms or if communication errors persist after bus troubleshooting.

Product Guarantee

GE provides a 1-year standard warranty for GE DS200SDCIG2AHB, covering material defects, workmanship issues, and compliance with UL 61010-1/CE/IEC 61800-5-1 standards from the date of shipment. This warranty includes free replacement of faulty units and 24/7 access to GE’s global technical support team—specialized in Mark V digital control and communication troubleshooting—to resolve issues like logic execution errors, communication bus failures, or I/O channel faults. For critical applications (e.g., nuclear power turbine auxiliaries), GE offers extended warranties (up to 2 years) and on-site commissioning services, where technicians validate GE DS200SDCIG2AHB’s signal processing accuracy, communication stability, and diagnostic functionality. GE also provides OEM-certified repairs for GE DS200SDCIG2AHB, restoring modules to factory specifications with a 6-month post-repair warranty—ensuring long-term reliability for Mark V turbine auxiliary control and integration systems.