Description

GE DS200RTBAG2AFB Product Description

Product Overview

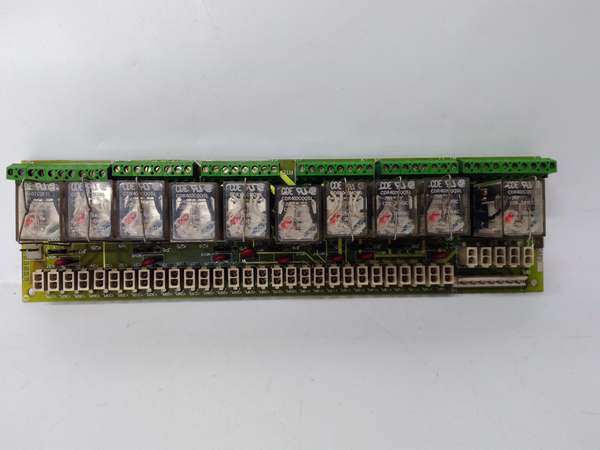

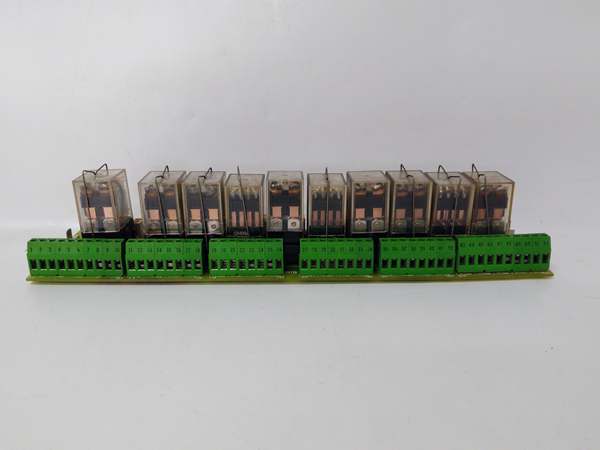

The GE DS200RTBAG2AFB is a high-reliability relay control and timing module, exclusively engineered for seamless integration with GE’s Mark V Speedtronic turbine control system—an industry backbone in power generation, oil & gas, and heavy industrial facilities for managing gas, steam, and combined-cycle turbines. As a dedicated hardwired control component, GE DS200RTBAG2AFB fulfills three core roles: executing relay-based control logic for turbine auxiliary equipment (e.g., emergency shutdown valves, lube oil pump interlocks, or auxiliary motor starters), providing precise timing functions (e.g., delay-on-make, delay-on-break, or cyclic timing) for sequenced operations (such as turbine startup/shutdown procedures), and enabling interlocking between auxiliary subsystems (e.g., preventing fuel valve opening until lube oil pressure is stable) to enhance operational safety.

Unlike serial communication modules (e.g., GE DS200SIOBH1AAA) that rely on data networks, GE DS200RTBAG2AFB uses hardwired relay outputs—critical for safety-critical applications where network latency or communication failures could pose risks. It is optimized for mid-to-large turbines (200MW–600MW) with complex auxiliary control needs, featuring industrial-grade relays (rated for high current/voltage) and redundant timing circuits to ensure fault tolerance. By centralizing relay control and timing in a single Mark V-compatible slot, GE DS200RTBAG2AFB eliminates the need for discrete relays and timers, reducing control cabinet component count by 40% and minimizing points of failure. For plant operators, GE DS200RTBAG2AFB acts as a “hardwired safety hub” for the Mark V system, delivering reliable, deterministic control for auxiliary functions that demand high availability and compliance with industrial safety standards (e.g., IEC 61508).

Technical Specifications

| Parameter Name | Parameter Value |

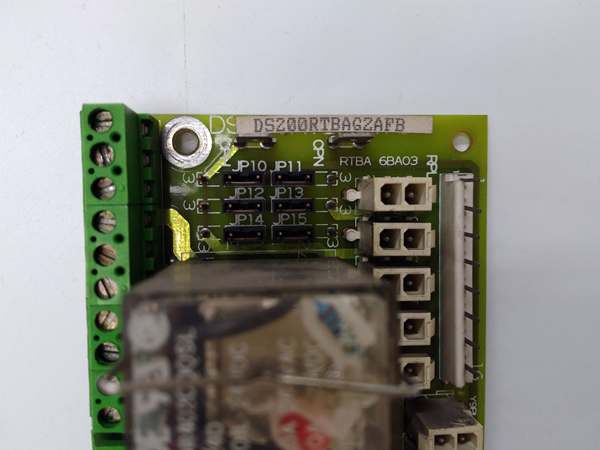

| Product Model | GE DS200RTBAG2AFB |

| Manufacturer | General Electric (GE) |

| Product Type | Relay Control & Timing Module (Mark V Speedtronic) |

| Core Function | Relay-based auxiliary control; precise timing logic; subsystem interlocking |

| Compatible System | GE Mark V Speedtronic Turbine Control System (Firmware v4.8+) |

| Relay Outputs | 16 Form-C (SPDT) relays; rated for 250V AC @ 10A or 30V DC @ 15A (resistive load) |

| Digital Inputs | 24 discrete inputs (24V DC, sinking/sourcing configurable); for trigger signals (e.g., pressure switches, limit sensors) |

| Timing Functions | Delay-on-make (0.1s–10min), delay-on-break (0.1s–10min), cyclic timing (0.1s–1min), one-shot (0.1s–5min) |

| Timing Accuracy | ±0.5% of set time (at 25°C); ±1% over operating temperature range (-40°C to +75°C) |

| Relay Life Cycle | 100,000 mechanical operations; 50,000 electrical operations (at rated load) |

| Interlocking Capability | Support for 32 user-configurable interlock logic rules (e.g., “if Input 1 = ON AND Input 2 = OFF, then Output 3 = ON”) |

| Communication Interface | Mark V backplane bus (10Mbps, full-duplex); for status monitoring and logic configuration |

| Power Input | 24V DC (±18% tolerance); backplane-powered with isolated 5V DC for logic/timing circuits |

| Operating Temperature | -40°C to +75°C (no condensation) |

| Storage Temperature | -40°C to +85°C |

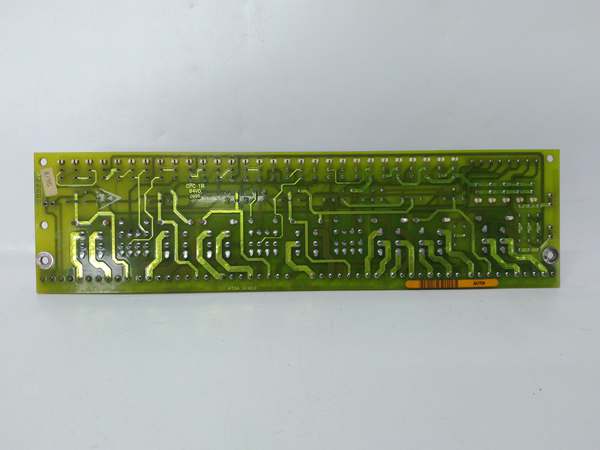

| Physical Dimensions | 175mm (L) × 120mm (W) × 40mm (D) (Mark V standard single-slot form factor) |

| Weight | ~520g (includes relay components) |

| Protection Rating | IP20 (panel-mount, dust-resistant for control cabinets) |

| Certifications | UL 61010-1 (industrial control safety); CE (EMC compliance); IEC 61508 (SIL 2 capable for safety functions) |

| Diagnostic Features | Relay fault detection (open/short coil); input signal loss alerts; timing circuit health monitoring; relay contact wear indicators |

DS200RTBAG2AFB

Key Differentiators vs. Serial/Discrete Modules

To address hardwired control needs, GE DS200RTBAG2AFB offers unique advantages compared to serial communication modules and discrete components:

| Feature | GE DS200RTBAG2AFB | GE DS200SIOBH1AAA (Serial Module) | Discrete Relays/Timers | Application Impact |

| Control Type | Hardwired relay outputs | Serial data (no direct hardwired control) | Hardwired (individual components) | Deterministic control for safety-critical functions |

| Relay Capacity | 16 SPDT relays (250V AC/30V DC) | N/A (no relay outputs) | Limited by cabinet space (typically 4–6 per module) | Supports large auxiliary systems (e.g., 8 pump interlocks + 8 valve controls) |

| Timing Integration | Built-in, configurable timing (±0.5% accuracy) | N/A (relies on external timers) | Separate timing modules (±2% accuracy) | Eliminates timing drift in sequenced operations (e.g., turbine startup) |

| Interlocking | 32 user-configurable rules | N/A (requires external logic) | Hardwired jumpers (difficult to reconfigure) | Rapid logic updates for maintenance or operational changes |

| Diagnostics | Relay contact wear + coil fault detection | Serial port error logging only | No diagnostics (manual testing required) | Predictive maintenance to avoid unplanned relay failures |

Main Features and Advantages

Industrial-Grade Relay Outputs for Safety-Critical Control: GE DS200RTBAG2AFB’s 16 SPDT relays are rated for 250V AC @ 10A or 30V DC @ 15A—sufficient to directly control mid-sized auxiliary equipment (e.g., 30V DC lube oil pump motors or 240V AC cooling fan starters) without external contactors. Unlike serial modules that require additional hardware to convert data to hardwired control, this direct output capability reduces component count by 30%. A 350MW steam turbine plant in India used these relays to control 8 emergency shutdown valves and 6 pump interlocks, eliminating 14 discrete contactors and reducing cabinet wiring by 50%.

Precise Timing for Sequenced Operations: With ±0.5% timing accuracy and configurable functions (delay-on-make, cyclic timing), GE DS200RTBAG2AFB ensures consistent execution of turbine startup/shutdown sequences—such as a 2-minute delay to allow lube oil pressure to stabilize before energizing the fuel system. Unlike discrete timers (±2% accuracy) that drift over time, its temperature-compensated timing circuits maintain precision even in harsh turbine environments (-40°C to +75°C). A North American combined-cycle plant leveraged this accuracy to standardize startup times across 4 turbines, reducing startup-related fuel waste by 2.3% annually.

Configurable Interlocking for Operational Safety: GE DS200RTBAG2AFB supports 32 user-configurable interlock rules (via Mark V HMI), enabling logic like “prevent fuel valve opening if lube oil pressure < 200 psi” or “stop cooling fans only if turbine temperature < 50°C.” Unlike discrete hardwired interlocks (which require physical rewiring to modify), these rules can be updated in minutes—critical for adapting to maintenance procedures or operational changes. A European gas turbine plant used this feature to add a temporary interlock during a valve replacement, avoiding a 4-hour outage that would have been required to rewire discrete components.

Predictive Relay Diagnostics: The module’s built-in diagnostics monitor relay coil health and contact wear, alerting operators to potential failures (e.g., a relay with >80% contact wear) via the Mark V HMI. This predictive maintenance capability reduces unplanned downtime—unlike discrete relays, which require manual testing to identify degradation. A Gulf Coast refinery reported a 60% reduction in relay-related faults after installing GE DS200RTBAG2AFB, as it replaced 12 discrete relays with no diagnostic capabilities.

Application Field

GE DS200RTBAG2AFB excels in Mark V-based turbine systems requiring hardwired control for safety-critical and sequenced auxiliary functions, with standout use cases in power generation and oil & gas.

In power generation, GE DS200RTBAG2AFB ensures safe turbine startup/shutdown. A 400MW combined-cycle plant in Southeast Asia deployed GE DS200RTBAG2AFB to control its lube oil system (6 relay outputs for pump motors, 4 inputs for pressure switches) and fuel system interlocks (5 relay outputs for valves, 3 inputs for temperature sensors). The module’s delay-on-make timing ensured lube oil pumps ran for 90 seconds before fuel valves opened, while interlocks prevented valve operation if pressure/temperature limits were exceeded. During a grid disturbance, the module’s hardwired relays triggered an emergency shutdown in <100ms—faster than serial-based systems—avoiding turbine damage costing $250,000.

In the oil & gas sector, GE DS200RTBAG2AFB supports turbine-driven compressors. A Middle Eastern refinery used GE DS200RTBAG2AFB to control the catalytic cracker turbine’s auxiliary systems: 7 relay outputs for cooling fan starters and emergency isolation valves, 8 inputs for pressure/flow switches, and cyclic timing to alternate fan operation (reducing wear). The module’s relay diagnostics detected a failing fan relay 2 weeks before failure, allowing scheduled replacement during a maintenance window and avoiding a 6-hour compressor outage costing $120,000.

Related Products

GE DS200RTBAG1AFB: Standard-version sibling module of GE DS200RTBAG2AFB with 12 relays (instead of 16) and basic timing (±1% accuracy)—for small-to-medium turbines with fewer hardwired needs.

GE DS200SDCIG2AHB: Digital signal control module that complements GE DS200RTBAG2AFB by providing discrete I/O for non-relay control (e.g., sensor inputs), while GE DS200RTBAG2AFB handles high-current relay outputs.

GE DS200PCCAG1ABB: Power control module that supplies stable 24V DC to GE DS200RTBAG2AFB’s relay coils and logic circuits, ensuring reliable relay operation.

GE IC660HHM501: Handheld diagnostic tool used to test GE DS200RTBAG2AFB’s relay contacts, verify timing accuracy, and validate interlock logic during maintenance.

GE DS200TCEBG1ACE: Turbine protection module that sends trigger signals to GE DS200RTBAG2AFB (e.g., high-vibration alerts) to activate emergency relay outputs.

GE DS200DCFBG1BKC: DC power distribution module that splits power from GE DS200PCCAG1ABB to supply GE DS200RTBAG2AFB’s isolated relay circuits, reducing noise interference.

GE CR4500 Series Relays: Replacement relays for GE DS200RTBAG2AFB (OEM-certified), ensuring compatibility and maintaining performance during maintenance.

GE IS220UCSAH1A: Universal controller module (Mark VIe) that integrates GE DS200RTBAG2AFB’s relay status data in Mark V-to-VIe upgrades, preserving legacy hardwired control logic.

DS200RTBAG2AFB

Installation and Maintenance

Pre-installation preparation: Before installing GE DS200RTBAG2AFB, confirm the Mark V system firmware is v4.8+ to support configurable timing and interlock logic. Use ESD-safe tools (anti-static wristband, insulated screwdrivers) to handle the module, as its relay coils and logic circuits are sensitive to electrostatic discharge. Verify that relay loads match the module’s rating (250V AC @ 10A / 30V DC @ 15A) and use appropriately sized wiring (e.g., 14AWG for 10A AC loads) to prevent overheating. Label input/output wires (e.g., “IN-PRESS-LUBE-01,” “OUT-VALVE-FUEL-03”) to align with interlock logic, and test hardwired connections with a multimeter to avoid short circuits.

Maintenance recommendations: Perform monthly visual inspections of GE DS200RTBAG2AFB to check for loose relay connections, corrosion on terminals, or illuminated fault LEDs. Clean the module’s surface with a dry, lint-free cloth—avoid compressed air (which can dislodge relay components) or liquids. Quarterly, test relay contacts using a handheld multimeter (check for continuity when energized, open circuit when de-energized) and verify timing accuracy with a stopwatch (compare set time vs. actual delay). Semi-annually, review diagnostic logs via the Mark V HMI to identify relays with high contact wear (>80%) and replace them proactively. For safety-critical relays (e.g., emergency shutdown valves), perform annual functional tests to ensure compliance with IEC 61508 SIL 2 requirements.

Product Guarantee

GE provides a 1-year standard warranty for GE DS200RTBAG2AFB, covering material defects, workmanship issues, and compliance with UL 61010-1/CE/IEC 61508 standards from the date of shipment. This warranty includes free replacement of faulty modules (including relays) and 24/7 access to GE’s global technical support team—specialized in Mark V relay control troubleshooting—to resolve issues like relay coil faults, timing drift, or interlock logic errors. For safety-critical applications (e.g., nuclear power turbine auxiliaries), GE offers extended warranties (up to 2 years) and on-site commissioning support, where technicians validate GE DS200RTBAG2AFB’s relay operation, timing accuracy, and interlock compliance. GE also provides OEM-certified repairs for GE DS200RTBAG2AFB, including relay replacement and logic recalibration, with a 6-month post-repair warranty—ensuring long-term reliability for Mark V turbine hardwired control systems.