Description

Product Overview

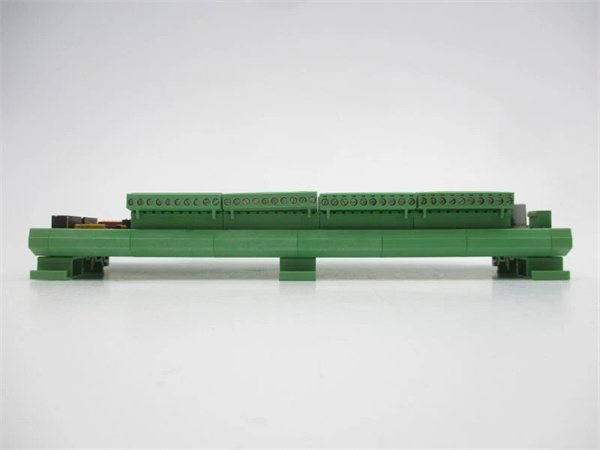

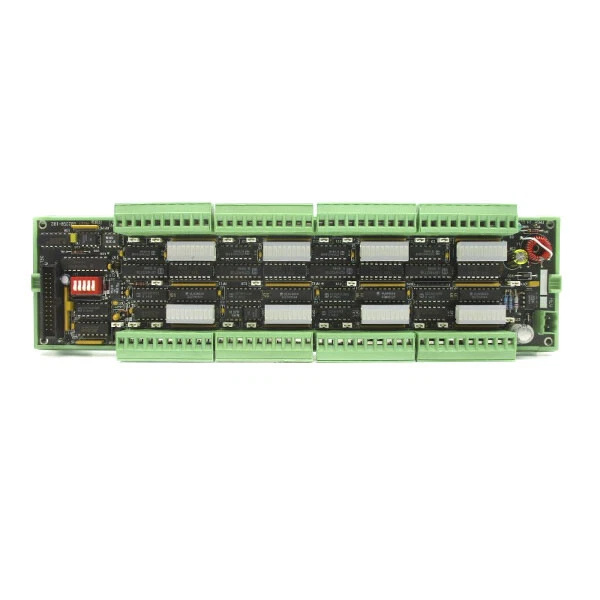

The DELTA TAU 602226 – 102 is a high – performance motion control product from DELTA TAU, a well – respected company specializing in automation and motion control solutions. As a key offering in their product lineup, the DELTA TAU 602226 – 102 is engineered to meet the complex and precise requirements of modern motion control systems. It serves as a critical component in a wide range of industrial automation applications, ensuring smooth, accurate, and efficient movement of machinery and equipment.

This product is designed to provide advanced motion control capabilities, including precise positioning, velocity control, and torque regulation. Its core functions enable seamless integration with various motors, such as servo motors and stepper motors, allowing for the creation of highly customized motion profiles. Whether deployed in CNC machining centers, robotic assembly lines, or advanced manufacturing equipment, the DELTA TAU 602226 – 102 offers reliable performance and exceptional control, enhancing the productivity and quality of industrial processes. It empowers manufacturers to achieve higher levels of automation, precision, and flexibility in their operations.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | 602226 – 102 |

| Manufacturer | DELTA TAU |

| Product Type | Motion Control Module |

| Input Voltage | 24 V DC (±10%) |

| Output Current per Channel | 3 A |

| Number of Control Axes | 4 |

| Communication Interfaces | Ethernet (EtherCAT), RS – 485, CAN |

| Maximum Positioning Resolution | 16 – bit encoder support (up to 65536 counts per revolution) |

| Control Modes | Position, Velocity, Torque |

| Operating Temperature Range | 0°C – 50°C |

| Relative Humidity Range | 5% – 95% non – condensing |

| Dimensions (W×H×D) | 120 mm × 100 mm × 50 mm |

| Weight | 0.5 kg |

| Protection Level | IP20 |

DELTA TAU 602226-102

Main Features and Advantages

Multi – Axis Precision Control

The DELTA TAU 602226 – 102 stands out with its ability to control up to 4 axes simultaneously, enabling complex multi – dimensional motion. It offers high – resolution positioning, thanks to its support for 16 – bit encoders, ensuring that machinery moves with extreme accuracy. In a CNC machining application, for example, this precision allows for the creation of intricate parts with tight tolerances, improving product quality and reducing waste. The module’s precise control over position, velocity, and torque across multiple axes makes it an ideal choice for applications that demand synchronized and accurate motion.

Versatile Communication Capabilities

Featuring multiple communication interfaces including Ethernet (EtherCAT), RS – 485, and CAN, the DELTA TAU 602226 – 102 enables seamless integration into various automation networks. EtherCAT provides high – speed, real – time communication, allowing for quick data transfer and responsive control, which is crucial for high – speed motion applications. The RS – 485 and CAN interfaces offer flexibility in connecting to a wide range of devices and legacy systems. This versatility ensures that the module can be easily incorporated into existing automation setups, reducing integration time and costs.

Robust and Compact Design

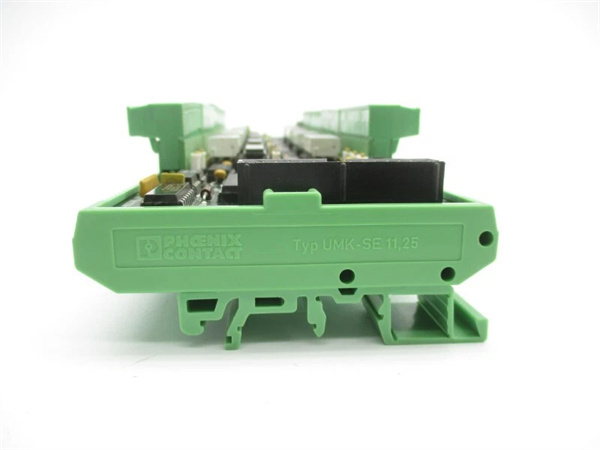

Despite its powerful functionality, the DELTA TAU 602226 – 102 has a compact form factor, making it suitable for installations where space is limited. Its robust design allows it to operate reliably within a temperature range of 0°C – 50°C and withstand moderate levels of humidity. The IP20 protection level safeguards the module from dust and accidental contact, ensuring long – term durability in industrial environments. This combination of compactness and robustness makes it a practical choice for a variety of industrial settings, from small – scale manufacturing cells to large – scale production facilities.

DELTA TAU 602226-102

Application Field

In the CNC machining industry, the DELTA TAU 602226 – 102 is widely used to control the movement of milling machines, lathes, and grinders. It enables precise cutting, drilling, and shaping operations, ensuring that workpieces meet strict dimensional requirements. By providing accurate motion control, it helps increase machining efficiency and reduce the need for post – processing adjustments.

For robotic assembly lines, the DELTA TAU 602226 – 102 plays a crucial role in controlling the movement of robotic arms. It allows robots to pick, place, and assemble components with high speed and accuracy, improving the overall productivity of the assembly process. The multi – axis control feature is particularly useful for complex robotic maneuvers, such as those required in electronics manufacturing or automotive assembly.

In the packaging industry, the module is used to control the motion of packaging machines, ensuring that products are accurately positioned, wrapped, and sealed. Its precise control capabilities help optimize the packaging process, reduce material waste, and enhance the quality of the packaged products. Additionally, in the textile and printing industries, the DELTA TAU 602226 – 102 enables smooth and accurate movement of machinery, contributing to the production of high – quality textiles and printed materials.

Related Products

- DELTA TAU 602226 – 103: An upgraded version of the DELTA TAU 602226 – 102, the 602226 – 103may offer additional control axes, higher output current capabilities, or enhanced communication features, making it suitable for more complex motion control applications.

- DELTA TAU 602225 – 102: This model has a lower number of control axes (2 axes) compared to the DELTA TAU 602226 – 102. It is a more cost – effective option for applications that require basic motion control of fewer axes, such as simple pick – and – place operations or single – axis positioning systems.

- DELTA TAU Motion Control Software: Specifically designed to work with DELTA TAU motion control products like the 602226 – 102, this software provides an intuitive interface for programming and configuring motion profiles. It enables users to easily set up complex motion sequences, monitor system performance, and perform diagnostics, enhancing the overall usability and functionality of the motion control module.

- DELTA TAU Servo Drives: These servo drives are complementary products to the DELTA TAU 602226 – 102. They convert the control signals from the motion control module into power signals to drive servo motors, ensuring smooth and accurate motor operation. Different models of servo drives offer varying power ratings and features to match the requirements of different motor sizes and applications.

- DELTA TAU Encoder Feedback Modules: Encoder feedback is essential for accurate motion control, and these modules work in tandem with the DELTA TAU 602226 – 102. They receive encoder signals from the motors and provide real – time position and velocity feedback to the motion control module, enabling closed – loop control and ensuring precise positioning.

Installation and Maintenance

Pre – installation preparation: Before installing the DELTA TAU 602226 – 102, carefully read the installation manual provided by DELTA TAU. Ensure that the installation environment meets the specified temperature and humidity requirements. Check the power supply to confirm that it is within the 24 V DC (±10%) range. Mount the module on a suitable surface using the provided mounting brackets, and ensure that there is sufficient space around it for proper ventilation. Connect the communication cables and power supply cables according to the wiring diagram in the manual, and make sure all connections are secure to prevent loose connections that could cause communication failures or electrical issues.

Maintenance recommendations: Regularly inspect the DELTA TAU 602226 – 102 for any signs of physical damage, loose connections, or abnormal operation. Clean the module periodically using a dry, soft cloth to remove dust, which can affect its heat dissipation and performance. Monitor the operating temperature of the module during operation; if it exceeds the specified range, check for proper ventilation and ensure that the power supply is stable. Periodically update the firmware of the module as recommended by DELTA TAU to benefit from the latest features, performance improvements, and security enhancements. In case of any malfunctions, such as communication errors or inaccurate motion control, refer to the troubleshooting guide in the user manual or contact DELTA TAU’s technical support team for assistance.

Product Guarantee

DELTA TAU stands firmly behind the quality and reliability of the DELTA TAU 602226 – 102. The product is covered by a comprehensive quality assurance program that adheres to strict industry standards. DELTA TAU offers a standard warranty period, during which any manufacturing defects will be addressed promptly with free repair or replacement services. Their dedicated technical support team, consisting of experts with in – depth knowledge of motion control systems, is available to assist customers with installation, operation, and maintenance. Whether customers encounter technical issues, need advice on system integration, or have questions about product performance, DELTA TAU’s support ensures timely and effective solutions, reflecting the company’s confidence in the product and its commitment to customer satisfaction in the motion control industry.